Definition of Structural Health Monitoring

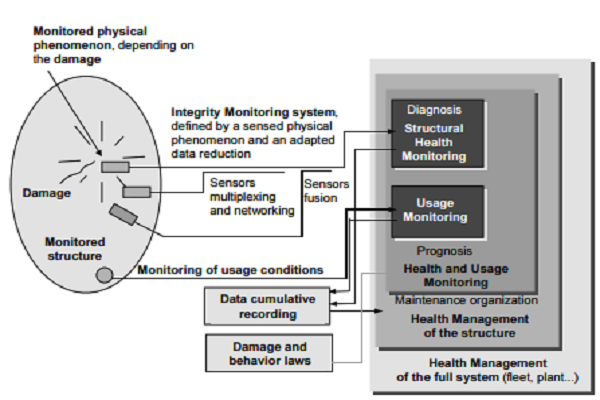

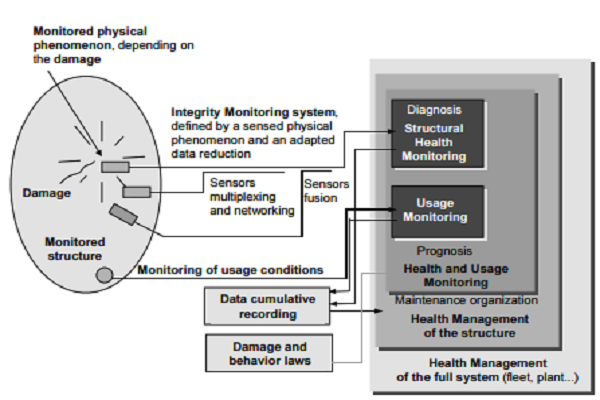

Structural Health Monitoring (SHM) aims to give, at every moment during the life of a structure, a diagnosis of the “state” of the constituent materials, of the different parts, and of the full assembly of these parts constituting the structure as a whole. The state of the structure must remain in the domain specified in the design, although this can be altered by normal aging due to usage, by the action of the environment, and by accidental events. Thanks to the time-dimension of monitoring, which makes it possible to consider the full history database of the structure, and with the help of Usage Monitoring, it can also provide a prognosis (evolution of damage, residual life, etc.). If we consider only the first function, the diagnosis, we could estimate that Structural Health Monitoring is a new and improved way to make a Non-Destructive Evaluation. This is partially true, but SHM is much more. It involves the integration of sensors, possibly smart materials, data transmission, computational power, and processing ability inside the structures. It makes it possible to reconsider the design of the structure and the full management of the structure itself and of the structure considered as a part of wider systems. This is schematically presented in the figure below:

Organization of a SHM system

In this figure, the organization of a typical SHM system is given in detail. The first part of the system, which corresponds to the structural integrity monitoring function, can be defined by: i) the type of physical phenomenon, closely related to the damage, which is monitored by the sensor, ii) the type of physical phenomenon that is used by the sensor to produce a signal (generally electric) sent to the acquisition and storage sub-system. Several sensors of the same type, constituting a network, can be multiplexed and their data merged with those from other types of sensors. Possibly, other sensors, monitoring the environmental conditions, make it possible to perform the usage monitoring function. The signal delivered by the integrity monitoring sub-system, in parallel with the previously registered data, is used by the controller to create a diagnostic. Mixing the information of the integrity monitoring sub-system with that of the usage monitoring sub-system and with the knowledge based on damage mechanics and behavior laws makes it possible to determine the prognosis (residual life) and the health management of the structure (organization of maintenance, repair operations, etc.). Finally, similar structure management systems related to other structures which constitute a type of super system (a fleet of aircraft, a group of power stations, etc.) make possible the health management of the super system. Of course, workable systems can be set up even if they are not as comprehensive as described here.

Health Monitoring of Civil Structures

Commonly known as Structural Health Assessment (SHA) or SHM, this concept is widely applied to various forms of infrastructures, especially as countries all over the world enter into an even greater period of construction of various infrastructures ranging from bridges to skyscrapers. Especially so when damages to structures are concerned, it is important to note that there are stages of increasing difficulty that require the knowledge of previous stages, namely:

- Detecting the existence of the damage on the structure

- Locating the damage

- Identifying the types of damage

- Quantifying the severity of the damage

It is necessary to employ signal processing and statistical classification to convert sensor data on the infrastructural health status into damage info for assessment.

Components

SHM System’s elements include:

- Structure

- Sensors

- Data acquisition systems

- Data transfer and storage mechanism

- Data management

- Data interpretation and diagnosis:

- System Identification

- Structural model update

- Structural condition assessment

- Prediction of remaining service life

An example of this technology is embedding sensors in structures like bridges and aircraft. These sensors provide real time monitoring of various structural changes like stress and strain. In the case of civil engineering structures, the data provided by the sensors is usually transmitted to a remote data acquisition centers. With the aid of modern technology, real time control of structures (Active Structural Control) based on the information of sensors is possible