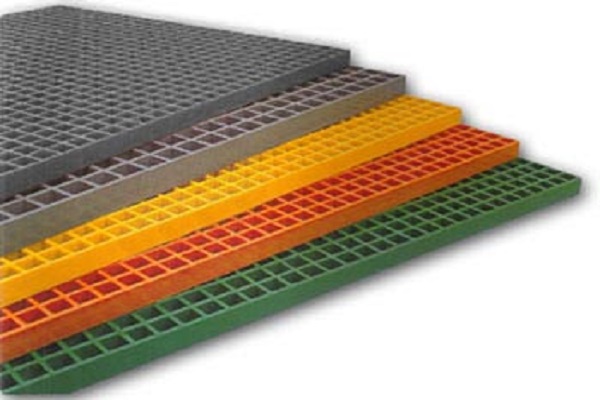

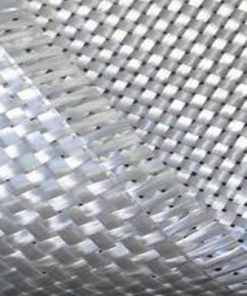

The Fiberglass Reinforced Plastic Grate (FRP grate) is made from unsaturated polyester and fiberglass. It is the pultrusion technology to turn slabs with a certain opening rate.

FRP Grating has the strength of steel, but it won’t corrode like steel can.

Advantages:

- Light weight with high strength. Easy for cutting and installation.

- No metal, never rust and corrosion resistance.

- Antiflaming, insulation and nonmagnetic.

- Impact resistance, hard material not liable to warp.

- Varied design and specifications is suit for your demand.

- Anti-skidding with slightly elastic, comfortable in stepping it.

- Long service cycle, and free for maintaining.

- Colors for chosen, excellent appearance.

Common Sizes and Applications:

Common sheet sizes for FRP grating include: 4’x8′, 4’x12′, and 3’x10′.

Common thicknesses include: 1″, 1.5″ and 2″.

Our molded FRP gratings have applications in many industries, including:

· chemical processing

· food & beverage

· marine

· oil & gas

· power

· manufacturing

· construction

· pharmaceutical

· metals & mining

· pulp & paper

· recreation

· water parks

· telecommunications

· IT server farms

· shipping centers

· transportation facilities

· water & waste treatment, and

· numerous architectural uses.

Be the first to review “FRP Grating”