PRODUCT DESCRIPTION

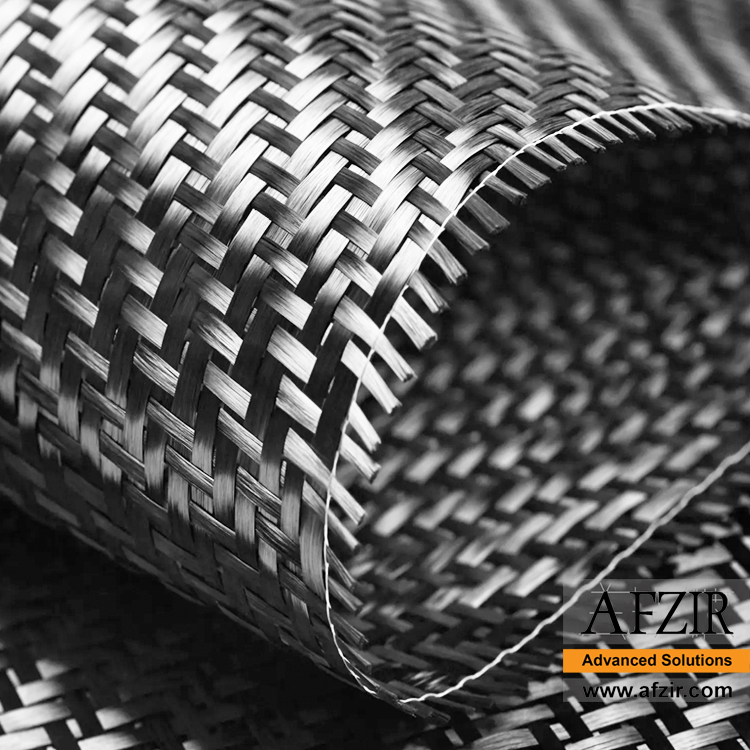

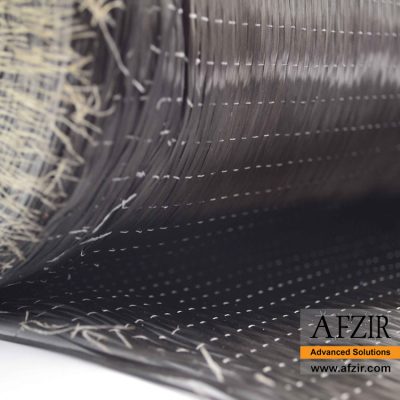

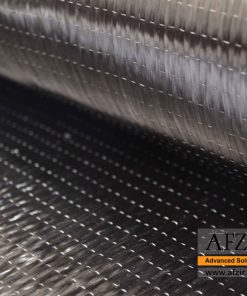

bidirectional carbon wrap have many applications in industry due to their very high tensile strength against low weight. Bidirectional carbon wrap is used in the fields and different industries such as composite, aerospace, war, medicine and sports equipment and in general in any field and industry that requires composite materials. One of the most important applications of CFRP composites is in the construction and building retrofitting.

bidirectional carbon wrap is used in most residential and industrial concrete structures. carbon wrap is a very light yet very durable compound. The structure of carbon wrap is up to 10 times stronger than that of steel. In addition to special features such as lightness or durability, easy installation conditions, anti-corrosion capability and also no need for maintenance of carbon fiber fabric should be mentioned.

Afzir Company produces bi-directional carbon wrap in different samples weighing 160 to 600 grams per square meter in all construction activities. The density of bidirectional carbon wrap represents the strength and fabrication of the final carbon fabric, which should be used according to the project conditions and engineering requirements.

Advantages of bidirectional carbon wrap increase the final bending capacity of reinforced concrete

- fast and clean installation

- bidirectional carbon wrap is cured at ambient temperature

- Prevents concrete bleeding

- keep moisture in the concrete until the concrete is finally dry

- Increase the tensile strength of concrete

- Corrosion resistance

- Has less permeability than steel beams

- Bidirectional carbon wrap could be implemented with various finish coatings.

- Being very flexible

What is the purchase price of various fabrics and carbon wrap?

bidirectional carbon wrap has a high value compared to other known fibers with high strength and has a higher price in the market.

the idea of using carbon fiber has revolutionized the construction of today’s very strong structures. now the commercialization approach of this product has changed. Carbon fiber is another well-known compound that has emerged from the study phase, experiencing commercialized mass-produced patterns on an industrialized scale.

Until a few years ago, you had to spend about $ 15 per pound of carbon fiber. But for now, each pound of these fibers cost just $ 7. Numerous factors play a role in the production to commercialization of each product. Factors such as raw materials, energy, scientific development as well as industrial capabilities are influential in creating modern technologies in the production and supply of each product. Especially for the commercialization and production of carbon fiber, they play a role more than any other product.

If you are trying to use carbon wrap in two directions and you want to design different and durable structures with the art of using carbon fiber and for this purpose you are looking for a manufacturer of carbon fiber composites, you are now in the right place. Afzir Reinforcement is one of the domestic pioneers in the supply and sale of bidirectional carbon fabric, which offers its products. You can contact Afzir specialists for professional advice on choosing the right type of carbon fabric.

Key Features

- High tensile strength

- Corrosion resistant

- Lightweight with an insignificant thickness

- Excellent electrical conductivity

- Very low thermal expansion coefficient

- Compatible with a variety of adhesives and resins, including FRP epoxy adhesive, polyester resin, and more.

Applications

- Structural strengthening and seismic retrofitting

- Enhancing the load-carrying capacity of structural components

- Repairing damaged elements of structures

- Effective defect remediation

- Mitigating blast effects on structures

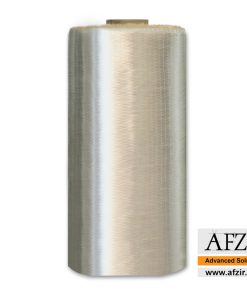

Packaging

- Thicknesses 0.09-0.34 and widths of 50 and 100 mm

Colour

- black

technical specifications

| Arial Weight |

160-600 gr/m² |

| Fabric Thickness |

0.09-0.34 mm |

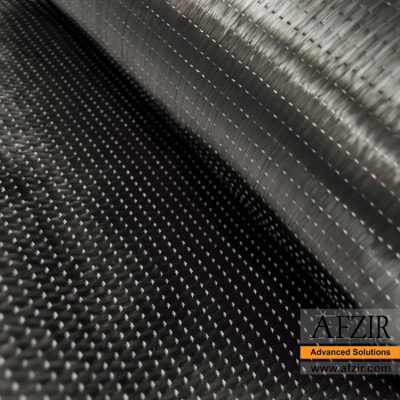

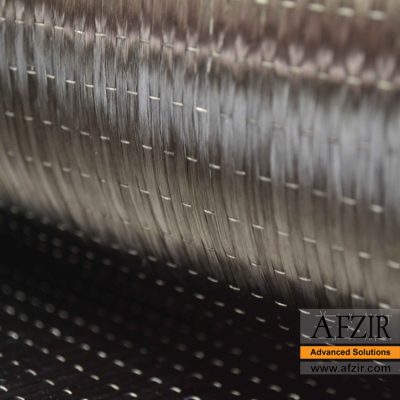

| Weave Pattern |

bidirectional |

| Primary Fiber Direction |

0° and 90° |

|

Width (mm) |

50-100 mm |

|

color |

black |

|

Comparison of properties of bidirectional carbon wrap with conventional construction steel |

||

|

parameter |

Bidirectional fiber |

steel |

|

Tensile Strength |

4900MPa |

360MPa |

|

Tensile Modulus |

230GPa |

200GPa |

|

Density |

1800Kg/m³ |

7850Kg/m³ |

|

Corrosion resistance |

Yes |

No |

|

Acid resistance |

Yes |

No |

In general, the reinforcement of structures is done in order to increase the bearing capacity of the building, improve the defects caused by corrosion and erosion, increase the ductility of the structure, the need to change the use of the structure and compensate for design and execution errors.

bidirectional carbon fibers are corrosion resistant and have high tensile strength, and its low weight, which is one of the goals of retrofitting, has led to an increasing use of them in seismic retrofitting and improvement projects.

In order to perform reinforcement in projects, it is necessary to thoroughly examine the current condition of the structure, such as the current bearing capacity of the elements, defects, the calculation files of the structure, and the existing documents and drawings of the structure.

General principles of bidirectional carbon wrap reinforcement system design

General principles and general design method are based on the limit state to provide an acceptable level of performance and safety, and due to less knowledge of FRP composites than other available materials such as concrete, it is necessary to apply strength reduction coefficients. So that the design reliability coefficient is more than 3.5. It is also necessary to measure the properties of existing materials such as compressive strength, modulus of elasticity and… by tests such as core drilling and compressive strength testing and ultrasonic testing.

Types of behavior of bidirectional carbon wrap

Tensile behavior of bidirectional carbon wrap

Under direct tensile loading, the carbon fibers have no plastic behavior before rupture. The tensile behavior of materials is characterized by an elastic linear stress-strain relationship until sudden failure occurs. Tensile strength and hardness of materials depend on several factors. Since fibers play an essential role in bearing in FRP composite, the type of fibers, orientation and also their amount of them play the most important role in tensile properties.

Compressive behavior of components reinforced with bidirectional carbon wrap

bidirectional carbon fiber that acts as an outer covering should not be used as a compression reinforcement. However, in columns, due to the confinement behavior of compressive resistant fibers and the capacity of the column increases indirectly.

Evaluation and acceptance

To evaluate the FRP system, the direction of the fibers, the presence of layer separation and adhesion to the surface, the location of the layers and… and Also, the compliance or non-compliance with the design drawings should be checked by the supervisory body, which we will refer to some of the cases and tasks of the supervisory body.

To use bidirectional carbon fiber in projects, these materials must be controlled based on laboratory information about these materials. Laboratory information is provided by the supplier company.

After installing and obtaining the strength of CFRP composites, the adhesive tensile test (Pull-Off test) is performed on the core samples and the adhesive resistance must be more than 1.4 MPa to observe the phenomenon of separation and rupture in concrete. If the strength is less than the specified value or the FRP system separates from the concrete, it indicates that the system is defective and the carbon fiber cannot provide the expected performance.

To evaluate and approve the installed fibers, other things should be considered, some of which we will mention:

- Occurrence of separation phenomenon

- For the placement of the layers, the direction is very important and the presence of deflection even by 5 degrees from the specified direction can have a great impact on reducing resistance.

- Thickness after curing with resin

- The length of the fiber splice

Rehabilitation goals

In general, the purpose of reinforcement is to increase the tolerance of the structure against various forces, especially earthquakes. Of course, the purpose of reinforcement is not always to increase the resistance of the structure to earthquakes and can have other causes such as change of use of a building and reduced the quality of materials. Building retrofitting can be considered in two types of buildings:

- Existing and in use buildings

- Earthquake-damaged buildings

Since the demolition and replacement of existing buildings with the new ones is very costly and time-consuming, so the importance of retrofitting buildings is increasing day by day.

Requirements for retrofitting in the building

In the following, we refer to the cases that in case of any of them, we need to present a plan and implement retrofitting in the building:

existing damage in old building

One of the most common cases in buildings is damage and defects during the use of the building. These damages can be seen in different forms in buildings. honeycombing, abnormal cracks and corrosion of rebars in beams, columns and roofs can be considered as common failures in concrete buildings, although many of these cases are not easily detected and Need to perform various methods of concrete testing, including corrugation, rebar scanning and …

Executive errors

Mistakes that occur during the implementation phase need to be investigated by retrofitting experts. These errors can occur in many different ways in different buildings, such as weakness in concrete test specimens, inconsistency of concrete design strength with existing strength, beam and column buckling, honeycombing, and so on.

Change of use of a building

These days, Changes in the use of buildings are common and are among the cases in which the building must be thoroughly examined by experts before doing so. Changes in the use of the building create new forces in the members of the building for which the building is not designed, and their emergence may cause severe breakage and damage to the load-bearing members such as beams, columns and… In these cases, it is necessary for the experienced consulting engineer to fully evaluate the existing structure and perform the feasibility of change of use in order to finally provide a plan with high accuracy and complete details.

detection of defects in a proper time and choosing the right solution will save a lot of building costs. Since choosing an inappropriate method of strengthening, repairing or retrofitting a structure can even make matters worse, it is necessary to seek the help of experienced and expert people in this field.

As there are various retrofitting solutions, employers also have different options for it and they must choose one of these methods to implement in their projects. Reinforcement using unidirectional carbon fiber is a method that is becoming more and more widely used. But what are the most important reasons for the pervasiveness of unidirectional carbon fiber retrofitting?

high resistance, low weight, Lack of conductivity of electricity, reduction in costs and…

There are also problems that other common methods of retrofitting, such as steel and concrete jackets, create for the building, such as weight gain, changes in architecture, disruption of long-term use of buildings, rising costs, and so on. The possibility of recurring problems such as corrosion and rust all add to the benefits of reinforcement using bidirectional carbon fiber.

The details of the implementation of bidirectional carbon fibers depend on the geometry of the structure, the smoothness of the substrate and so on, and It is necessary for the contractor to use FRP materials in accordance with the specifications described by the consulting engineer, such as type of fibers, type of resin, number of layers, method of execution and… in performing reinforcement operations.

Steps of implementing bidirectional carbon wrap

Carbon fiber reinforcement systems should be implemented according to the following steps and carefully to achieve the desired quality.

Concrete repair and substructure preparation

It is necessary to eliminate all the defects in the main concrete and the underlying concrete, which may affect the integrity of the CFRP composite, before applying the fibers, and also in cases where there is a possibility of corrosion and rust of the rebars in the concrete, Corrosion and sediments should be cleaned and damaged.

Mixing resins

Mixing of resins should be done according to the procedure recommended by the manufacturer in accordance with the technical specifications of the project. All resin components must be mixed at a suitable temperature and in sufficient quantity until the material

A variety of methods for installing bidirectional carbon wrap

After preparing the substrate, it is time to install FRP fibers, which have different methods and the installation method must be specified by the consultant. Here are some ways to install FRP fibers:

bidirectional carbon wrap wet gluing system

In this installation method, the fiber system is installed by hand without corrosion or dry resin. The fibers can be fertilized and impregnated in a separate process with the help of a device impregnated with resin materials and then installed on the concrete surface.

Pre-impregnated fiber system

unidirectional pre-impregnated systems are first impregnated with resin at the factory, but the resin is not cured. These fibers are bonded to surfaces with or without additional resin and cured on site.

Failure to comply with any of the above and other cases expressed by the consultant and the manufacturer will cause a weakness in the bearing of the system and in some cases the fibers will be separated from the surface. Fibers will prevent:

- Avoid sticking bidirectional carbon wrap on the inner surface of the corners as much as possible and observe sufficient development length

- overlap should be applied to the patched areas

After the implementation of the FRP system, it is necessary to implement quality assurance and control programs and programs by the quality control unit (QC). Quality control should be done through a series of required inspections and tests.

Quality control inspectors should be fully familiar with the FRP system and how to implement and install it, and during the installation of the unidirectional carbon fiber system should conduct daily inspections, which should include the following:

- Ambient temperature, relative wetness and weather conditions

- The dryness of the surfaces

- Surface preparation methods

- Observe the resin curing process

- The position and size of any layer separation or the presence of air bubbles

The quality control unit should also periodically inspect and evaluate the implemented CFRP composite.

Types of FRP system evaluation methods

General inspections

With general visual inspections, any changes in color, fiber separation, cracking, etc. are examined, and the presence of any of these factors indicates a weakness in the system and improper execution. The nature of FRP composite materials is such that they should never or very rarely be repaired during operation, so surfaces covered with FRP materials should be generally monitored and inspected.

One of the common failures in FRP systems is the separation of concrete composite materials, which is a very dangerous failure that if it occurs, the FRP system is practically inefficient. Therefore, the separation of concrete composite materials should be evaluated. The best way to diagnose this condition is to perform a pull-off test, which should be done at regular intervals according to the regulations. Make a correction for it. If minor damage to the composite material is detected, it can be repaired by methods such as resin injection with caution so that the material is not further damaged. If general and more significant damage, such as scaling or separation of layers, occurs on a large scale, adhesives and composites may need to be removed. Defective materials are removed from the concrete surface on a large enough surface and the cleaned part is re-coated with new materials.

Long-term monitoring and inspection

According to the monitoring and inspection system, like all structural members, the reinforcement system with unidirectional carbon wrap must be monitored and inspected. Such measures for bridges are usually carried out once a year in general and every six years in detail, but regular inspections of buildings are rarely carried out. Building quality control engineers need to justify regular monitoring and inspection of reinforced members, and CFRP composite reinforced buildings should be regularly monitored and inspected for reinforced members.

technical documents

Photo Gallery

Technical documentation request

Frequently Asked Questions

What are bidirectional carbon wraps?

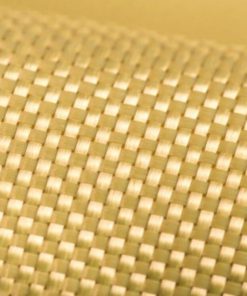

bidirectional carbon wraps are fibrous fabrics woven from carbon fiber yarns in two perpendicular directions (0 ° and 90 °).

What are the applications of bidirectional carbon fiber?

bidirectional carbon fiber fabrics are used as reinforcing materials to increase the bearing capacity of the structure, repair defects, deflection control, increase flexural and shear strength, reduce the effect of explosion on structural elements, etc.

What are the weight types of bidirectional carbon wrap?

bidirectional carbon wrap is available in weights of 160, 200, 320 to 600 grams.

What is the difference between bidirectional carbon wrap and unidirectional carbon fabric?

bidirectional carbon wrap, with the blur texture of carbon fiber yarns, applies the mechanical properties of carbon fibers in two directions and can simultaneously reinforce the structural element in two or two directions perpendicular to each other. But unidirectional carbon wrap benefits from the mechanical properties of carbon fiber in only one direction, and the damaged structural elements reinforce the structure in only one direction.

Under what conditions should we store bi-directional carbon fiber fabrics?

bidirectional carbon fiber fabrics should be stored at 10 to 40 ° C in a dry place away from direct sunlight. Bidirectional carbon wrap can last up to about 10 years if stored in tight, closed boxes.

What is the price of bi-directional carbon fiber?

The price of bidirectional carbon wrap is determined depending on the desired weight and dimensions. Due to market fluctuations, the price of construction reinforcement products also varies. For this purpose, you can contact the experts of Afzir Company to inquire about the up-to-date price of carbon fiber.

What resins are bi-directional carbon fiber fabrics compatible with?

bidirectional carbon fibers, like unidirectional carbon fibers, are compatible with resins such as epoxy resin, vinyl ester resin and polyester resin. But for the highest performance, epoxy resin and vinyl ester resin are preferred.

What are the two methods of installing carbon fiber fabric?

bidirectional carbon wrap can be applied by methods such as wet gluing system or pre-impregnated system to the desired surfaces.

Can bidirectional carbon wrap be used to reinforce concrete?

bidirectional carbon wrap are compatible with concrete. This type of fibrous fabric, together with the relevant resin, is attached to damaged or defective concrete surfaces in various ways. These reinforcing materials can greatly improve the mechanical properties of concrete such as flexural and shear strength, toughness, heat resistance, useful life of concrete, etc.

Can bidirectional carbon fiber be used on steel surfaces?

In general, steel and carbon fiber are compatible with each other. Therefore, bi-directional carbon fiber fabrics can also be used with steel. carbon wrap with resin (CFRP) as reinforcing materials for steel elements, can increase its bearing capacity by up to 75%.

Be the first to review “Bidirectional Carbon Wrap”