PRODUCT DESCRIPTION

CBA™, short for Concrete Bonding Adhesive, is a high-quality binder formulated explicitly for effectively bonding fresh cementitious materials to various surfaces. This versatile adhesive is suitable for creating strong connections between new concrete and a wide range of materials, including concrete, stone, wood, steel, ceramic, and brick.

When using CBA™, it is essential to apply it to clean, durable surfaces free from contaminants. This adhesive is particularly useful for bonding new concrete to existing surfaces such as epoxy-based concrete, steel, brick, glazed tile, ceramic, mosaic, and concrete floors.

With its exceptional adhesion properties, CBA™ enables reliable and long-lasting bonds, making it ideal for reinforcing structures, repairing damaged concrete surfaces, and seamlessly integrating different flooring materials. Its compatibility with various substrates makes it a preferred choice among construction professionals seeking reliable and efficient bonding solutions.

By utilizing CBA™, you can achieve strong and durable connections between different materials, significantly enhancing your construction projects’ longevity and structural integrity.

Features of the Product:

- Excellent adhesion to concrete and most building materials

- Achieves excellent initial and final resistances

- Demonstrates good tensile strength

- Offers stability against impact and wear

- Compatible with both dry and wet substrates

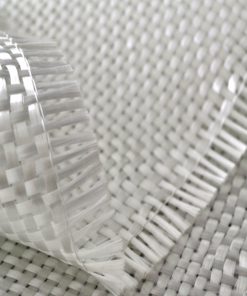

- Exhibits good moisturizing properties and the ability to impregnate woven and non-woven fibers

- Possesses low concentration and high penetrating power

- Has an insignificant smell and is safe for users

- Allows for easy mixing and provides a long working time

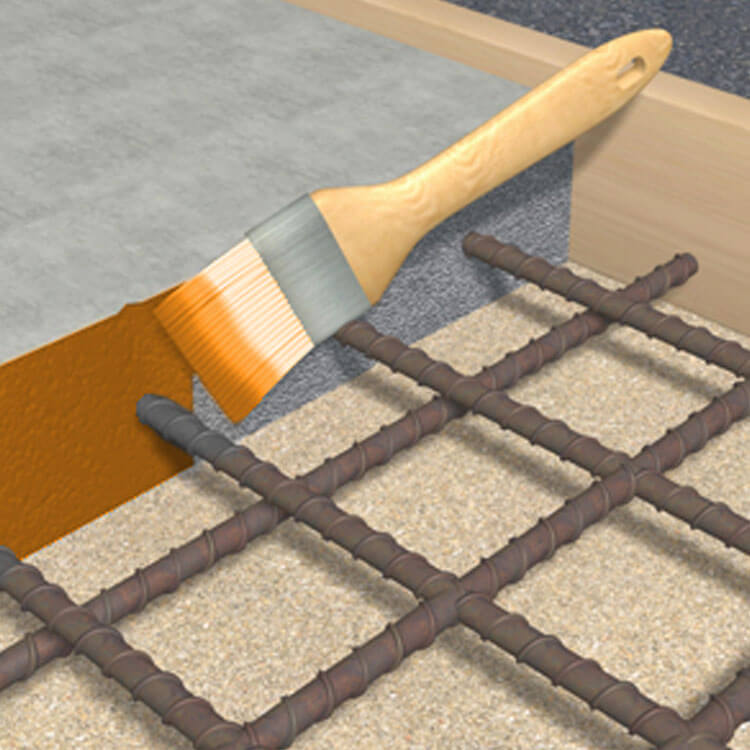

- Can be applied with a roller or brush.

Which factors affect the price of CBA™?

Several factors can influence the price of CBA (Concrete Bonding Adhesive):

-

Quality and Brand:

Established brands known for high-quality materials may have higher-priced CBAs due to their reputation and investments in research and development.

-

Product Formulation:

CBAs with specialized formulations, such as additives for faster curing or increased bond strength, may have a higher price point.

-

Packaging and Quantity:

Larger quantities or bulk packaging options generally cost less per unit than smaller packages or specialized packaging formats.

-

Market Demand:

Supply and demand dynamics in the construction industry can impact CBA prices, with high demand potentially leading to price increases.

-

Distribution and Location:

Factors like shipping costs, distance to the market, and local market conditions can affect the overall pricing of CBAs.

Considering these factors when assessing CBA prices allows for informed decision-making, balancing both cost and quality.

Features

- Excellent adhesion to concrete and most building materials

- Achieves excellent initial and final resistance

Demonstrates good tensile strength - It offers stability against impact and wear

Compatible with both dry and wet substrates

Exhibits good moisturizing properties and the - ability to impregnate woven and non-woven fibers

- Possesses low concentration and high penetrating power

- It has an insignificant smell and is safe for users.

- It allows for easy mixing and provides a long working time.

- It can be applied with a roller or brush.

Applications

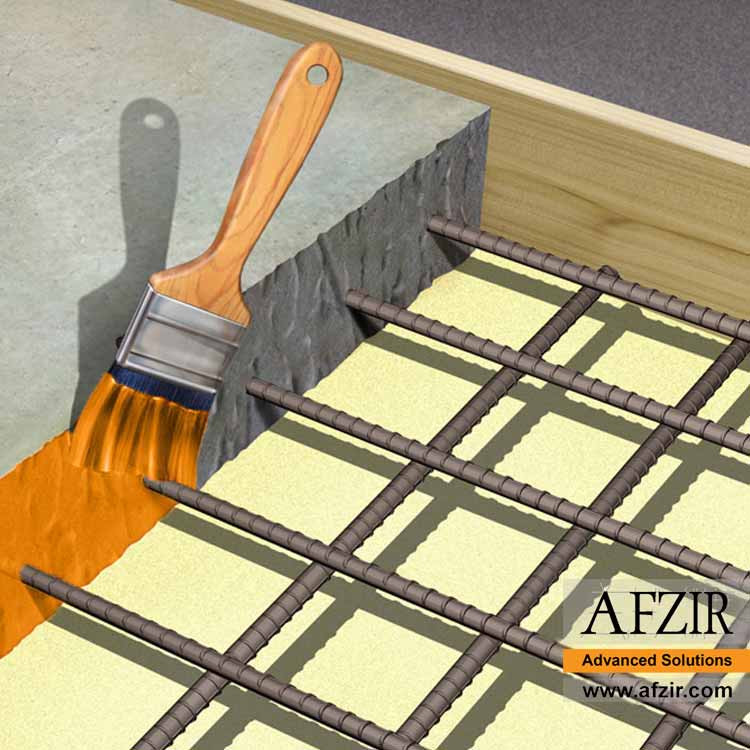

- Adhesion of fresh concrete or mortar to hardened concrete in vertical and horizontal applications.

- Bonding of precast hardened concrete to existing horizontal concrete.

- Suitable for various construction applications, including buildings, roads, bridges, factories, etc.

- Compatible with both dry and damp surfaces.

- Suitable for internal and external use.

- Compatible with reinforced concrete structures.

- Can be used for planting steel rebar in wet holes.

- Used as a binder to cover or adjust the height of columns.

Packaging

Colour

technical specifications

|

Appearance of the product |

liquid |

| Initial setting time |

6 hours |

| final setting time |

7 days |

| Pot life |

4 hours |

| Operating temperature |

-35 to 65 ℃ |

| Mixing ratio |

A:B=100:13 |

|

density |

1.55Kg/L |

|

compressive strength |

60MPa |

| Tensile strength |

20MPa |

| Adhesion stability |

2.5MPa |

|

Flexural strength |

30MPa |

Here is a summarized list of recommendations for engineers working with CBA™ (Concrete Bonding Adhesive):

- Surface Preparation: Ensure surfaces are clean, prepared, and contaminant-free.

- Follow the Manufacturer’s Instructions: Adhere to instructions for proper application, mixing ratios, and curing times.

- Test Compatibility: Conduct small-scale compatibility tests before large-scale applications.

- Use Appropriate Tools and Equipment: Select suitable tools for application, such as brushes, rollers, or trowels.

- Adhere to Safety Precautions: Wear protective gear and ensure proper ventilation.

- Consider Environmental Conditions: Consider temperature, humidity, and air circulation during application.

- Implement Quality Control and Inspection: Regularly inspect work for necessary adjustments or touch-ups.

- Consult Manufacturer or Experts: Seek guidance from technical support or experienced professionals when needed.

- Prepare the Surface: Ensure thorough cleaning and removal of loose materials or contaminants from the surface before applying CBA™.

- Follow the Manufacturer’s Instructions: Adhere to the recommended guidelines provided by the manufacturer for proper mixing ratios, application techniques, and curing times.

- Conduct Compatibility Tests: Test the compatibility of CBA™ with the specific materials and substrates involved by performing small-scale tests before full-scale application.

- Use Appropriate Tools and Equipment: Use the right tools, such as brushes, rollers, or spray equipment, for precise and efficient application of CBA™.

- Prioritize Safety: Take necessary safety precautions, including wearing appropriate protective gear and ensuring proper ventilation during the application process.

- Consider Environmental Factors: Consider factors like temperature, humidity, and air circulation to ensure optimal conditions for the application and curing of CBA™.

- Implement Quality Control: Regularly inspect the work to ensure proper bonding and application of CBA™, making necessary adjustments or touch-ups.

- Seek Expert Advice: Consult the manufacturer’s technical support or seek guidance from experienced professionals for any specific challenges or complex projects.

When applying CBA™ (Concrete Bonding Adhesive), following proper application instructions for optimal results is important. Here are the general application guidelines:

- Surface Preparation: Ensure the surface is clean and properly prepared, free from loose materials. Remove any dirt, dust, oil, grease, or contaminants hindering adhesion.

- Mixing: Follow the manufacturer’s instructions for mixing CBA™. Use the recommended mixing ratios and ensure thorough mixing to achieve a uniform consistency.

- Application Method: CBA™ can be applied using a brush, roller, or trowel, depending on the project’s specific requirements. Choose the most suitable method for the surface and desired application thickness.

- Apply Evenly: Apply CBA™ evenly onto the prepared surface, ensuring complete coverage. Avoid leaving any gaps or thin spots that may compromise the bonding strength.

- Working Time: Take into account the working time of CBA™. Apply the adhesive within the recommended time frame to ensure proper bonding. Avoid applying CBA™ beyond its operating time, as it may affect adhesion.

- Bonding Fresh Concrete: When bonding fresh concrete to hardened concrete or other surfaces, apply CBA™ to the fresh and receiving surfaces. Ensure that both surfaces are coated adequately before joining them together.

- Curing: Follow the curing instructions provided by the manufacturer. Allow sufficient curing time for the adhesive to strengthen before subjecting it to load or further construction activities.

- Clean Up: Clean tools and equipment immediately after use. CBA™ can be challenging to remove once it has hardened, so cleaning up promptly using the appropriate cleaning agents or solvents is essential.

Here is a summarized list of quality control measures for CBA™ (Concrete Bonding Adhesive):

- Inspection of Materials

Verify product condition, expiration date, and specifications. - Surface Preparation Check

Ensure surfaces are properly cleaned and prepared. - Adhesion Testing

Perform tests to verify bonding strength. - Mixing and Application

Monitor proper mixing ratios and even application. - Coverage and Bond Inspection

Check for complete coverage and proper bonding. - Curing time

Record and monitor curing time. - Durability and Performance Testing

Conduct tests to assess long-term performance. - Documentation and Recordkeeping

Maintain detailed records of quality control activities. - Ongoing Monitoring

Continuously monitor bonded surfaces for performance evaluation.

technical documents

Photo Gallery

Technical documentation request

Be the first to review “Epoxy Adhesive For Concrete Bonding”