PRODUCT DESCRIPTION

What is multi-purpose epoxy adhesive?

Multi-purpose epoxy adhesive is a strong glue that consists of two components. It is specifically designed for bonding various common construction materials. This adhesive does not contain solvents and has a simple one-to-one mixing ratio, making it easy to use. It has the right thickness to be applied on both horizontal and vertical surfaces and effectively fills gaps on split surfaces. Once it hardens, the adhesive can be drilled, cut, or sanded as needed. It is suitable for a wide range of surfaces, including steel, glass, concrete, fiberglass, wood, cement, brick, stone, tile, ceramic, and other building materials. The adhesive is known for its exceptional strength, waterproof properties, and chemical resistance. It remains secure and does not shrink, making it ideal for indoor and outdoor applications.

How to mix multi-purpose epoxy adhesive?

Mixing multi-purpose epoxy adhesives is a simple process. The ratio is one part of component A to one part of component B, measured by volume. It’s important to mix the two components thoroughly. Pour the entire amount of component B hardener into the container of component A resin. Use a suitable drill with a mixing paddle to mix the components slowly. Continue blending for 2 minutes until a uniform gray color is achieved. Scrape the sides of the containers to ensure complete mixing. Be careful not to overmix, which can introduce air bubbles. If you work below 10°C, warm the components in hot water or keep them at room temperature (up to a maximum of 25°C) before mixing. Heating the components to 25 degrees Celsius will reduce the working time of the mixture to 45 minutes. Alternatively, store the materials at 20°C and only take them out when needed. Remember to mix only the amount of adhesive that can be used within the specified working time.

How to use multi-purpose epoxy adhesive?

Using multi-purpose epoxy adhesive is straightforward. Follow these steps:

- Use sandpaper or a file to Prepare the surfaces you want to bond by roughening them.

- Thoroughly clean the surfaces to remove dirt, dust, or grease.

- Cut the tip of the injection syringe and allow any air bubbles to rise for about 30 seconds.

- If you don’t have a mixer, dispense equal amounts of resin and hardener onto a disposable surface using a double plunger.

- Clean the syringe tip, then pull back the plunger and push it again to prime it.

- Quickly and thoroughly mix the epoxy resin and hardener for a few minutes until they are well combined.

- Apply a small amount of the adhesive to the surfaces you want to bond, ensuring they are properly aligned. Press them firmly together.

- The drying time may vary, so refer to the product instructions for specific guidelines.

- Carefully remove any excess epoxy using a cloth dampened with methyl alcohol.

The multi-purpose epoxy adhesive is available at a competitive price, offering excellent value for its quality and performance. Pricing may vary depending on the size and packaging options. Checking with authorized retailers or distributors for specific pricing details is recommended. Rest assured that investing in this adhesive will provide a reliable and durable solution for your bonding needs.

Features

- Excellent adhesion to pre-prepared surfaces

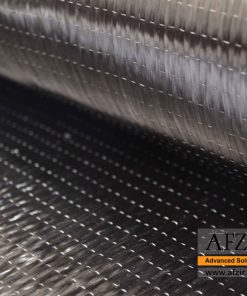

- Good adhesion with concrete, steel, wood, glass, rubber and carbon fiber

- Slight shrinkage during processing

- High humidity tolerance

- Able to run at temperatures between 5 and 45 degrees Celsius

- Easy installation

- High durability

- high resistance

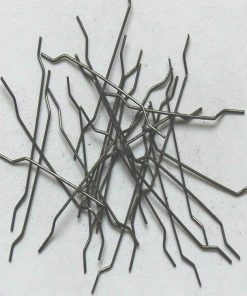

- Resistant to vibration and strong shocks

Applications

- Concrete-to-metal joints

- A solid material for joints of doors and windows

- A coating for injecting cracks in concrete and repairing damages

- Bonding new concrete to old concrete sections

- Use on roads, streets, bridges, sidewalks and factory loading areas

- Covering concrete surfaces against moisture

Packaging

- In 5 kg bags with hardener component

Colour

- Gray color (after mixing)

technical specifications

| Curing temperature |

10-30℃ |

|

Workable life |

30 min |

|

density |

1.3Kg/L for part A 1.2Kg/l part B 1.26Kg/L component |

|

Moisture resistance |

0.5% in 1.1mm 0.3% in 1.6mm |

| Tensile strength |

17N/mm2 |

|

Flexural strength |

35N/mm2 |

- Surface Preparation: Ensure surfaces are clean, dry, and contaminant-free.

- Mixing Ratio and Thorough Mixing: Follow recommended mixing ratio and blend components thoroughly.

- Application Techniques: Apply adhesive evenly and avoid excessive application.

- Working Time and Curing: Be mindful of working time and allow sufficient curing time.

- Environmental Considerations: Consider temperature, humidity, and substrate conditions.

- Testing and Quality Assurance: Conduct small-scale tests before full-scale application.

- Safety Precautions: Use proper safety gear and follow handling guidelines.

- Adhesive Storage: Store adhesive in a cool, dry place with sealed containers.

- Adhesive Compatibility: Confirm compatibility with intended materials and substrates.

- Manufacturer’s Guidelines: Refer to the instructions and technical data sheets.

Recommendations for Contractors Working with Multi-Purpose Epoxy Adhesive:

- Surface Preparation: Ensure thorough cleaning and preparation of surfaces before applying the adhesive.

- Adhesive Selection: Choose the appropriate multi-purpose epoxy adhesive based on the specific project requirements and substrate materials.

- Mixing Ratio and Consistent Mixing: Follow the recommended mixing ratio provided by the manufacturer and ensure thorough and consistent mixing of the adhesive components.

- Application Techniques: Use suitable tools and techniques to apply the adhesive evenly and uniformly on the surfaces.

- Working Time and Curing: Be aware of the working time and curing time of the adhesive to ensure proper bonding and allow sufficient time for the adhesive to cure.

- Temperature and Humidity Control: Consider the ambient temperature and humidity levels during application and curing, as they can affect the performance and curing process of the adhesive.

- Safety Precautions: Adhere to proper safety practices, including using appropriate personal protective equipment (PPE) and following safety guidelines provided by the manufacturer.

- Testing and Quality Assurance: Conduct preliminary tests or trials to ensure the adhesive’s compatibility, adhesion strength, and suitability for the project.

- Proper Storage and Handling: Store the adhesive in a controlled environment, following the manufacturer’s recommendations for temperature, humidity, and shelf life. Handle the adhesive with care to prevent contamination or damage.

- Manufacturer’s Guidelines and Documentation: Refer to the manufacturer’s instructions, technical data sheets, and other documentation for specific guidance on product usage, safety precautions, and troubleshooting.

- Surface Preparation: The substrate surface should be prepared using mechanical tools such as sandpaper or sandblasting to ensure proper adhesion. This will remove any weak surface layers or brittle materials. The substrate should have an inherent tensile strength greater than 1 N/mm2. It is recommended to perform a pull-off test before installing the adhesive. If the substrate is uneven, Afzir’s leveling mortars can be used to level the surface.

- Metal Surfaces: Lubrication before application is necessary for metal surfaces. If there is no corrosion present, cleaning with a wire brush is sufficient.

- Composition: The epoxy components are typically provided in two separate containers. Before combining them, it is important to thoroughly mix each component individually to prevent any sedimentation. Then, add the hardener to the resin and stir for 3 to 5 minutes using a low-speed drill and mixer. Continue mixing until a uniform and consistent color is achieved. In cold weather, it is recommended to store the adhesive in a warm environment for a few hours before use.

- Installation: The mixed adhesive should be used within its specified working time. Once the resin and hardener are combined, there are approximately 90 minutes (at 21°C) to utilize the material. Apply the adhesive onto the prepared substrate using a roller or hand while wearing gloves. Apply the adhesive to both surfaces before joining them together.

- Press the bonded sheets onto the substrate, ensuring no trapped air bubbles between them. Use a rubber roller to firmly press the sheets and achieve a consistent adhesion line with an approximate 2 to 3 mm thickness. Remove any excess adhesive from around the bonded area.

For optimal mixing, it is recommended to ensure that the temperature of the ingredients is around 22°C. If the product appears thick in colder temperatures, it can be warmed by placing the mixture in a bucket of warm water before mixing. In high ambient temperatures, it is advised to cool the multi-purpose epoxy in water to prevent rapid curing. To achieve the desired temperature, place the buckets of Part A and Part B separately in warm or cool water for at least 10 to 15 minutes. Subsequently, allow the material to return to room temperature (20-23 degrees Celsius).

The recommended application temperature range is 35 to 115 degrees Fahrenheit, and the service temperature range is -20 to +200 degrees Fahrenheit. The multi-purpose epoxy adhesive exhibits excellent chemical resistance to mild acids, caustics, detergents, gasoline, fuel oil, saltwater, and freshwater. It does not adhere to wax paper, Teflon, polyethylene, or other plastics. If there are doubts about its suitability for a particular surface, conducting a small test in a discreet area is advisable.

technical documents

Photo Gallery

Technical documentation request

Be the first to review “Epoxy Resin Adhesive”