PRODUCT DESCRIPTION

The joint expansion described is designed explicitly for highway bridges, considering that rubber exhibits high elasticity that changes with temperature, causing expansion deformation in the bridge structure. This rubber expansion joint offers various advantages, including easy installation, stable and smooth operation, waterproof and dust-proof properties, low noise levels, lightweight construction, and cost-effectiveness. The adhesive fills the bolt holes and joints at every meter during installation, ensuring excellent water-proofing. The product is manufactured using aging-resistant and wear-resistant rubber, capable of enduring repeated vehicle loads and providing a long service life.

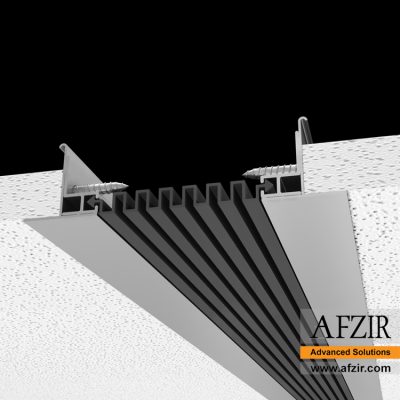

Structural elements, especially superstructures, experience length changes due to material shrinkage, temperature fluctuations, and varying loads. To prevent surface cracking and more severe damage, the length of each structural element is often limited, with gaps incorporated to accommodate movements. These gaps must be bridged and suitable for traffic under all expansion conditions. Steel or aluminum expansion joints have proven to be effective solutions. They facilitate length variations without constraints or cracking, protect adjacent structural element surfaces, and, when necessary, prevent water ingress.

Expansion joint usage can be considered as one of the methods to address damage caused by natural factors like storms and temperature fluctuations. Afzir’s incremental expansion joints mitigate the effects of bridge expansion and contraction due to environmental changes and natural factors. The installation location and spacing of the bridge’s expansion joints depend on various factors, including the bridge design, land type, and weather conditions at the construction site. The geometric shape of the bridge structure significantly influences the number, type, and characteristics of the expansion joints. The effectiveness of an expansion joint is influenced by the elastomeric rubber used. These bridge expansion joints ensure the bridge’s structural integrity, preventing breakage and increasing the service life and load resistance. Expansion joints are vital for the proper functioning of a bridge.

Improper operation of expansion joints can lead to various issues, including increased maintenance costs and cracks. Afzir’s elastomeric expansion joints are non-structural components designed to facilitate smooth passage over the gaps between bridge deck components and prevent damage caused by transfer and rotational movements of the slabs relative to each other. These movements can result from thermal expansion and contraction, shrinkage, creep, pre-stressing-induced elastic shortening, displacement due to load, or any other factor causing movement and rotation of the bridge slabs.

Elastomeric expansion joints find applications in many structures, particularly staircases. With their high strength and features, as mentioned above, these expansion joints can be utilized in various concrete and steel structures, including bicycle paths, sidewalks, railway stairs, bridges, longitudinal joints, hospitals, parking lots, and more. However, their most common use is in staircases. Additionally, installing elastomeric expansion joints in old bridges without existing expansion joints can achieve reinforcement, reconstruction, and replacement objectives.

Cost plays a crucial role in retrofitting projects. Suppose you are wondering about the price of an elastomeric expansion joint or the budget required to supply and implement such joints. In that case, it depends on factors like currency exchange rates, purchase quantity, and more. We recommend contacting expansion joint sales companies like Afzir Company to inquire about pricing. Afzir Company is actively involved in the sale of bridge expansion joints, and customers and contractors can obtain information regarding material requirements and expansion joint prices by contacting the company’s experts for advice.

Key Features

- High resistance to continuous impacts caused by traffic

- Abrasion resistance

- low weight

- High resistance to corrosion and adverse weather conditions

- Suitable insulation against water and sealing the bridge expansion joint

- Can be used in different temperature conditions

- Good deformation capability and good reversibility

- Increase the resistance of the structure to temperature changes

- Useful lifespan and high durability

- Increase the lifespan of structures such as stairs

- Increase the resistance of the structure to expansion and contraction

- Increase the resistance of the structure to seismic stresses and vibrations

- Ease of replacement

- High tensile strength

- Increased resistance of deck and backpacks to friction

- Reduce dead load in structures

- Resistance to cracks created by friction and required reconstructions in relation to these factors

Applications

- Strengthen bridges

- Reinforced concrete bridges

- Pre-stressed bridges

- Freeway bridges and highways

- Arched metal bridges

- Metal bridges with load-bearing cables

- As a break seam in the building

- As a discontinuous joint and expansion joint in parking lot

Packaging

- It can be provided in different lengths according to the type of project and conditions of use.

Colour

- Black

technical specifications

|

hardness |

60±5 Shore A

ASTM D2240 |

| Tensile strength |

≤25 MPa ASTM D412 |

| Elongation at break |

500±50 % ASTM D412 |

| Hardness change |

Max -5 Shore A ASTM D2240 |

| Tensile strength changes |

Max -15 % ASTM D412 |

| Length change |

Max -15 % ASTM D412 |

| Compression set |

16/15 % ASTM D395 After 24hr at 70°C |

| Ozone resistance |

No Crack ASTM D1149 After 96hr at 40°C |

|

Tensile strength tests of expansion joint rubber have been performed in the laboratory of Rubber Engineering and Research Company. |

|

Design calculations, expansion joint criteria, and the fastening of elastomeric expansion joints must be conducted and approved by reputable consulting engineering companies or reputable retrofitting companies.

In addition to manufacturing elastomeric expansion joints, Afzir Company offers comprehensive design services for stair reinforcement in compliance with regulations and standards such as ISO9001, European Standard EN 1337-5, Euro Codes Building the Future EC0, EC1, EC8, ASSHTO M297, and CNR 10018. These designs involve detailed analysis, considering project requirements, environmental factors, and other relevant considerations. Afzir Reinforcement Company is recognized as a leading provider of technical and engineering services, ensuring appropriate design factors are considered for various projects across Iran.

Please find below the specifications for each type of elastomeric expansion joint:

- Details of elastomeric expansion joint EXJ ™ T80

- Details of elastomeric expansion joint EXJ ™ T100

- Details of elastomeric expansion joint EXJ ™ T120

- Details of elastomeric expansion joint EXJ ™ T140

Please refer to the details above for specific information on each elastomeric expansion joint.

- Ensure Proper Training: Contractors should have specialized knowledge and training in Elastomeric Expansion Joint installation.

- Follow Manufacturer Guidelines: Adhere to the guidelines provided by the manufacturer for installation and maintenance.

- Conduct Site Assessment: Thoroughly assess site conditions and project requirements.

- Use High-Quality Materials: Use Elastomeric Expansion Joints from reputable manufacturers.

- Implement Proper Surface Preparation: Ensure surfaces are clean, smooth, and contaminant-free.

- Follow Correct Installation Procedures: Adhere to recommended installation techniques.

- Pay Attention to Bolting and Fastening: Ensure proper depth and placement of bolts for a secure connection.

- Regular Maintenance and Inspections: Establish a maintenance plan and conduct periodic inspections.

- Comply with Safety Regulations: Prioritize safety and follow relevant safety guidelines.

- Seek Expert Assistance if Needed: Consult professionals for guidance and expertise when required.

- Step 1: Install a steel plate and pave the surface with asphalt, then cut and remove the concrete from the bridge deck in the area designated for the expansion joint, with a 65-70 cm width.

- Step 2: Reinforce and connect the existing concrete reinforcement to the new one by inserting cane reinforcement.

- Step 3: Create a mold for the expansion joint based on the geometric dimensions of the rubber joint, ensuring the possibility of applying primer and grout to connect the old and new concrete.

- Step 4: Mark the drilling points on the newly poured grout according to the holes in the rubber expansion joint.

- Step 5: Drill holes with a diameter of 20 mm and a minimum depth of 170 mm, then insert galvanized bolts, size 16 mm, using rebar implant adhesive.

- Step 6: Install a sealing curtain or PVC sealing fabric on the grout surface to redirect any absorbed surface water away from the joint expansion system.

- Step 7: Install or replace the joint expansion rubber. Ensure that the surface for installing the elastomeric expansion joint is smooth, clean, and free from dust, grease, oil, and large cavities. Any rough areas should be leveled using suitable mortar or putty from Afzir Company.

- Step 8: Fill the holes and seams in the rubber expansion joints and other surfaces with depressions using Afzir Company’s environmentally resistant sealing mastic.

Afzir Reinforcement Company emphasizes the importance of carefully considering the depth and placement of bolts. Failure to plant the bolts at the recommended depth and improper connection of the new and old concrete to the elastomeric expansion joint system can lead to potential separation over time. Adhering to the principles of expansion joints is crucial, so it is recommended to have specialized and trained individuals handle the installation and execution of elastomeric expansion joints.

Please note that concrete damage and steel corrosion must be repaired using Afzir Company’s special epoxy-based repair mortar before the expansion joint rubber is applied.

Additionally, the expansion joint can be cut using a milling machine while observing all safety regulations. Avoid cutting this product with high heat.

- Incoming Material Inspection: Verify the quality and specifications of received expansion joints.

- Dimensional Checks: Measure the dimensions of expansion joints for compliance.

- Material Testing: Test the elastomeric material properties.

- Bond Strength Testing: Assess the adhesion between elastomeric material and other components.

- Visual Inspection: Check for surface defects and irregularities.

- Functional Performance Testing: Test the performance under operating conditions.

- Water Tightness Testing: Verify the resistance to water infiltration.

- Documentation and Traceability: Maintain records of inspections and compliance.

- Compliance with Standards: Ensure adherence to industry standards and specifications.

- Continuous Monitoring and Auditing: Implement ongoing quality control measures and improvements.

technical documents

Photo Gallery

Technical documentation request

Frequently Asked Questions

What are the types of elastomeric expansion joints produced by Afzir Company?

There are four types of T80, T100, T120, and T140.

What are the disadvantages of poor expansion joint performance?

Improper operation of expansion joints can cause many problems such as increased maintenance costs, cracks and so on.

What is the characteristic of elastomeric rubber used in expansion joints?

These elastomers imported from Germany are a type of high-strength rubber that has high temperature flexibility and compressive warp.

How do transitions and rotations occur?

Transitional and rotational displacement due to various causes in the structure such as thermal expansion and contraction, shrinkage or creep, elastic shortening due to pre-stressing, displacement of the structure due to load, or any other factor in which the bridge slabs face transitional movement. And rotate, they come into being.

What are the advantages of using elastomeric expansion joint in bridge structure?

Cracks due to temperature fluctuations can be prevented, as well as vibrations and frictions can be controlled and possible breakdowns can be prevented.

Be the first to review “Elastomeric Expansion Joint”