PRODUCT DESCRIPTION

The Fireproof Coating (code SFM™ 80) by Afzir is an exceptional structural fireproof mortar specifically designed for composite systems. This innovative product provides strong fire protection for a wide range of applications, ensuring the safety and integrity of composite materials in the face of fire hazards.

With its advanced formulation, SFM™ 80 offers outstanding fire resistance, capable of providing protection for composite fibers against fire for more than 4 hours. This single-component, sprayable mortar consists of specially selected fire-retardant materials, carefully blended to create a highly effective barrier against flames and heat.

The SFM™ 80 fireproof coating is primarily cement-based, comprising non-combustible and non-flammable components. Its unique composition allows it to act as a non-toxic, water-based fireproofing film that adheres to composite surfaces, forming a durable and high-quality protective layer.

One of the key features of SFM™ 80 is its compatibility with structural concrete. It can be seamlessly applied to existing structural concrete members with minimal concrete coating, significantly enhancing their fire resistance. This versatility makes it an ideal choice for retrofitting and upgrading fire protection measures in buildings.

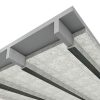

By incorporating SFM™ 80 into composite systems, structural members such as walls, roofs, and other components can benefit from its exceptional fire-retardant properties. This product plays a vital role in passive fire-resistance systems, ensuring compliance with safety regulations and meeting the requirements of the International Building Code for various structural applications.

With the Structural FireProof Mortar for Composite Systems, you can rely on Afzir’s expertise and commitment to delivering high-quality fire protection solutions. Safeguard your composite materials against fire hazards and create a safer environment with the reliable and effective SFM™ 80 fireproof coating.

Key Features

- Provide 4 hours of fire resistance

- High adhesion resistance

- Easy and fast installation and execution

- Affordable

- Suitable for use in a variety of structures

- Non-toxic

- Low odor

- Smooth architectural grade finish

- Fully trusted

Applications

- Fire protection coating on all structural components and public places such as: restaurants, hospitals, Nursing homes, schools, Corridors and stairs

- As FRP top coat in all elements reinforced with these FRP fibers

Packaging

- This product is offered in 20 liter buckets.

Colour

- grey

technical specifications

| color |

grey |

| Theatrical coverage (for 10 mm thickness) |

9.5 kg/m2 |

| Shelf time |

15 months |

| Density |

0.9-0.95 kg/cm3 |

| Specific weight |

600 kg/m3 |

| Heat transfer coefficient |

0.29 W/m oC |

| Compressive strength |

10.6 MPa |

- Familiarize yourself with the product: Understand the properties and application requirements of SFM™ 80.

- Conduct a thorough risk assessment: Evaluate fire hazards and identify critical areas needing fire protection.

- Consult with fire protection experts: Seek guidance from specialists experienced with SFM™ 80.

- Ensure proper surface preparation: Clean and prepare composite surfaces according to manufacturer’s recommendations.

- Follow recommended application guidelines: Adhere to spraying techniques and achieve the specified thickness.

- Conduct regular quality control checks: Monitor application and performance of SFM™ 80.

- Stay updated on regulations and codes: Keep abreast of relevant building codes and standards.

- Document and maintain records: Keep detailed records of the application process and inspections.

- Provide proper maintenance and upkeep: Regularly inspect and address any damages or deterioration.

- Collaborate with manufacturers and suppliers: Maintain communication for technical support and information.

- Acquire comprehensive product knowledge: Understand the properties and requirements of SFM™ 80.

- Collaborate with engineers and designers: Communicate and align with project stakeholders.

- Develop a detailed project plan: Create a comprehensive plan covering all aspects of the application.

- Ensure skilled and trained personnel: Assign experienced and trained workers.

- Adhere to safety protocols: Prioritize safety measures and compliance.

- Conduct site-specific risk assessments: Identify critical areas requiring fire protection.

- Optimize surface preparation: Follow guidelines for thorough surface cleaning and preparation.

- Implement quality control measures: Monitor application process and verify performance.

- Maintain accurate records: Document all aspects of the application.

- Provide client education and maintenance guidelines: Inform clients about benefits and maintenance requirements.

Bed preparation

The surface must be clean and dry and free of any materials. Concrete surfaces should be clean and covered with metal primers.

Combination

The fireproof coating for FRP must be mechanically agitated in the mixer at medium speed. Stir thoroughly to create a homogeneous mixture. Stirring should be done to prevent air from entering the mixer.

Performance

This product can be applied by using rollers, brushes and spraying on the desired surfaces. Fireproof coating for FRP of Afzir company will be applicable from one to several layers as needed. Do not apply too much and do not run the product at temperatures below 10 ° C.

- Pre-Application Inspection: Thoroughly inspect and prepare the substrate according to guidelines.

- Mixing and Consistency: Follow recommended mixing instructions for a homogeneous mixture.

- Adhesion and Compatibility: Test adhesion and compatibility with substrate materials.

- Application Thickness: Measure and monitor the uniform thickness of the coating during application.

- Drying and Curing: Allow proper drying and curing time as specified by the manufacturer.

- Visual Inspection: Conduct regular visual inspections for surface defects and coverage issues.

- Quality Assurance Testing: Consider relevant tests to ensure compliance and reliable results.

- Documentation and Reporting: Maintain detailed records of the process and report any deviations or corrective actions.

- Ongoing Monitoring and Maintenance: Regularly assess the coating’s condition and implement a maintenance program.

technical documents

Photo Gallery

Technical documentation request

Frequently Asked Questions

What kind of cover is a fire cover?

Fire proofing coating (code SFM ™ 80) of Afzir Company is a single-component product consisting of special fire-retardant materials that can be applied as a spray, which is designed to be used in the FRP system and to protect these fibers against fire.

What is the fire resistance of FRP fire retardant coating?

Fireproof coating can withstand fire for up to 4 hours.

What packaging does FRP fireproof coating come in?

FRP fire cover is supplied in 20 liter buckets.

How much does FRP fireproof coatings cost?

This product is impregnated by spraying on surfaces and semi-skilled manpower can easily work with it, so it has a low implementation cost.

What is FRP fireproof coating made of?

SFM ™ 80 fire retardant coating is based on cement and consists of non-combustible and non-flammable materials.

What colors are fireproof coatings available in?

This type of coating is available in gray.

Be the first to review “Structural FireProof Mortar for composite systems”