PRODUCT DESCRIPTION

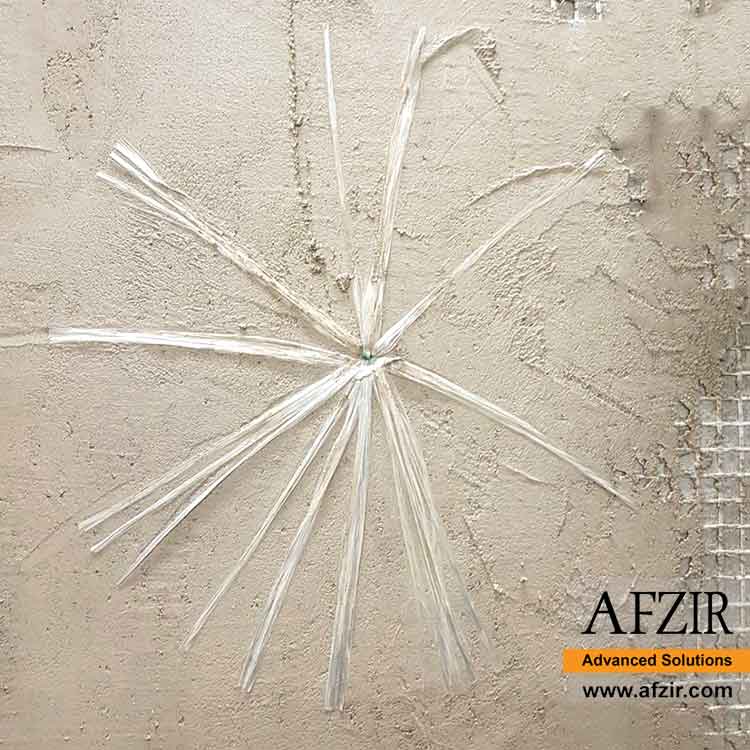

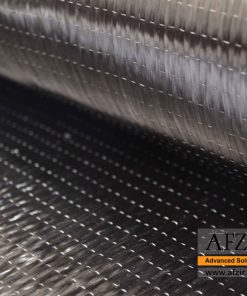

GSA™ spike anchors are factory-manufactured products composed of loose bundles of fiberglass. These anchors are designed to enhance the performance of FRP (Fiber Reinforced Polymer) materials by improving axial elongation and strengthening the interface between the surface and the composite fiber. As a result, the overall efficiency of the FRP composite fiber is significantly increased.

By incorporating GSA™ into FRP modification, the composite system experiences improved axial elongation properties and increased strength. This enhancement is crucial for ensuring the durability and reliability of structures. The GSA™ spike anchors effectively optimize the bonding between the surface and the FRP composite fiber, reducing the risk of debonding or separation.

The use of GSA™ spike anchors offers numerous advantages, including improved load-carrying capacity, enhanced structural integrity, and extended service life. These anchors are particularly beneficial for structures that require additional strength, such as buildings, bridges, and other infrastructure projects.

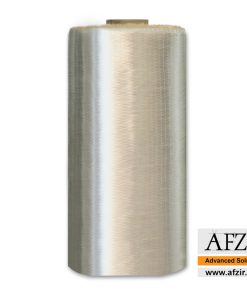

GSA™ spike anchors are available in various diameters and lengths, which can be customized to suit the specific needs of different structural projects. The manufacturing process involves bundling the unidirectional glass fibers and impregnating them with epoxy resin, resulting in a high-strength and durable material.

The use of GSA™ in conjunction with FRP provides a solution for strengthening structures that require high axial elongation and strength at the interface between the surface and the composite fiber. This innovative material improves the composite system’s efficiency, enhancing the structure’s overall strength and durability.

In addition to their excellent mechanical properties, GSA™ spike anchors are easy to install, making them a cost-effective solution for many projects. They require minimal surface preparation and can be easily bonded to various surfaces, including concrete, steel, and masonry. Overall, GSA™ spike anchors are a reliable and efficient material for improving various structures’ performance and load capacity.

Key Features

- High modulus of elasticity

- Very high mechanical, chemical and tensile resistance

- Resistant to corrosive environments

- Can be used at high and low temperatures

- It has the characteristic of self-handling and excellent durability

- light weight

- Resistant to electricity

- Long operating period

- Easy to install

- Decreasing the price of structural retrofitting

- Reducing the cost of strengthening with FRP

Applications

- Increasing the bearing capacity of various structures

- Seismic improvement of the structure and increase in resistance against increased load or earthquake force

- Reducing the weight of the structure compared to other strengthening methods

- To strengthen the FRP fibers in the end areas and border points (fiber cut areas)

- Use in cases where there is a possibility of separation of fibers from the surface of the structure.

- Use in cases where a high number of fiber layers is required in the structure.

- To reduce fiber consumption in strengthening with FRP systems

Packaging

Colour

- white

technical specifications

| color | white |

| Tensile strength | 3.2GPa |

| Tensile modulus | 70GPa |

| Compatible resins | epoxy, polyester and… |

| Storage temperature | 4℃-38℃ |

Necessary arrangements for installing glass anchors and spikes:

Preparation of the substrate (preparation of the substrate can have a significant effect on the quality of system performance):

All surfaces must be cleaned of dirt, grime, dust, oil, grease, wax and other contaminants.

In case of unevenness or contamination, the surfaces need grinding, sandblasting, pressure washing or other usual mechanical methods.

An industrial cleaner should be used to remove dust.

Note that concrete surfaces must be completely dry or clean to allow the adhesive to dry.

How to use SPIKE glass:

The design and calculations related to the use of Spike glass products are carried out according to the regulations and standard specifications by design engineers. We mark the desired place for anchors with a circle and make holes with a diameter of 12 mm. To ensure that the anchors sink completely inside the holes, the depth of the holes is 3 mm larger than the height of the anchors. After that, blow on the surface of the concrete and inside the holes with the available tools, so that the dust disappears and the surface and the hole are clean. Resin or other types of adhesives compatible with this system are used to impregnate FRP sheets, concrete surface and anchors. Then connect the FRP and the product execution is finished.

- All components of the composite FRP system may cause skin irritation and sensitivity, so the use of chemical resistant gloves is recommended.

- Avoid breathing vapors and dust and consult a doctor if breathing is difficult.

- Resin products can cause severe eye irritation. Avoid contact with eyes and use safety glasses.

- This method should not be performed in cold and humid weather.

technical documents

Photo Gallery

درخواست مدارک فنی

Error: Contact form not found.

Be the first to review “Glass Spike Anchor”