PRODUCT DESCRIPTION

ERS™ 200 is a two-part epoxy adhesive with exceptional bonding properties, ideal for impregnating high-strength and high-modulus fibers. It exhibits no shrinkage during hardening and offers excellent adhesion to building materials. This adhesive cures rapidly and provides remarkable mechanical and chemical stability. FRP epoxy adhesives are renowned for their superior adhesion, chemical and thermal resistance, mechanical properties, and electrical insulation. They exhibit excellent resistance to base solutions, making them suitable for applications involving tanks with mineral salts.

Application of FRP adhesive in structures and buildings

FRP epoxy adhesives and resins are widely used in construction and civil engineering thanks to their ability to bond large surfaces and heavy joints. They find applications in producing adhesives, plastics, paints, coatings, primers, sealants, flooring, and other construction products. They are commonly employed in constructing multi-layered wooden decks, walls, ceilings, and other items requiring solid connections to the substrate. The versatility of epoxy adhesives allows them to bond to various surfaces such as wood, metal, glass, stone, and certain plastics. They offer superior resistance to heat and chemicals compared to many other adhesives.

Retrofitting of concrete structures using FRP adhesive and resin

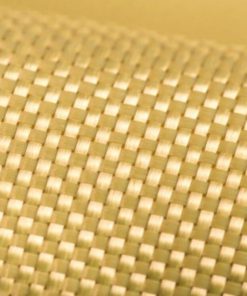

FRP composites, composed of a polymer substrate and high-strength continuous fibers like glass and carbon fibers, provide a simple, cost-effective solution for repairing and reinforcing concrete structures. On-site production of FRP composites through the wet lay-up process involves impregnating carbon or glass fibers with epoxy and bonding them to prepared concrete substrates. Once the FRP adhesive has cured, it becomes an integral part of the structure, functioning as an external reinforcement system. The process typically includes using a primer to enhance the adhesive-substrate bond, epoxy putty to fill voids and surface cracks, and saturated resin to impregnate the fabric and adhere it to the concrete substrate. A protective cover safeguards the FRP system from mechanical and environmental damage.

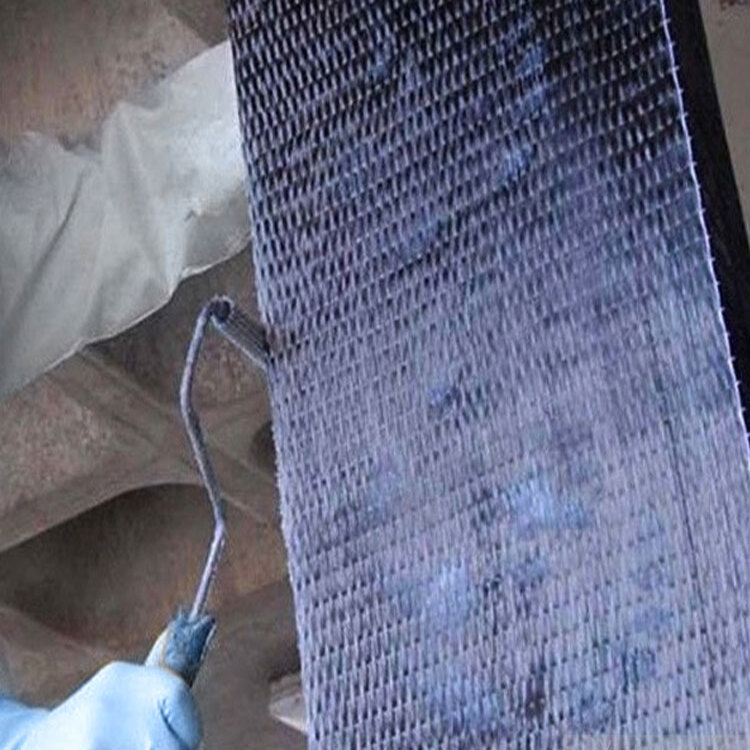

Wet lay up process

The wet lay-up process involves impregnating fibers with FRP epoxy adhesive and applying them manually to a prepared surface. Achieving desired properties requires observing the correct fiber-to-resin ratio. Generally, heavier fibers and reinforcing materials necessitate more significant amounts of resin for proper impregnation. The optimal ratio is typically 60% fiber to 40% resin.

Selecting the appropriate FRP epoxy resin

When choosing an adhesive or FRP fiber resin for your project, consider factors such as the required epoxy layer thickness, curing time, the need for a mold, desired wear resistance, impregnation of reinforcing material, special epoxy properties, and exposure to extreme temperatures, humidity, chemicals, UV light, or other harmful agents.

Priorities for choosing FRP epoxy

Ensure measured strength meets requirements. Consider curing time and hardening properties. Evaluate viscosity. Check waterproofing capabilities.

Key Features

- Excellent adhesion to concrete and most building materials

- Outstanding initial and final strength

- Remarkable chemical stability

- Impact and abrasion resistance

- Effective moisturizing and impregnation of FRP fibers

- Low concentration with high penetration power

- Slight odor and safe for users

- Easy mixing process

Applications

- Assembly of automotive parts

- Resin impregnation of carbon fiber and glass

Epoxy priming on concrete and construction surfaces - Bonding for epoxy repair mortars

- Rebar adhesion

- Versatile use as an epoxy adhesive in various applications

Packaging

- 23 kg buckets

Colour

- Clear light yellow liquid

technical specifications

| appearance |

Clear light yellow liquid |

| Part A |

Clear light yellow liquid |

| Part B |

clear |

| Shelf time |

18 month |

| Storage conditions |

Store dry at 4°C – 40°C |

| Chemical base |

Epoxy Resin |

| density |

1.1 Kg/L |

| Mixing ratio |

A:B = 100:13 |

|

Viscosity |

7000 -10000 MPa |

| Tensile strength (ASTM D638) |

35 MPa |

| pull off Adhesion testing |

2.5 MPa |

|

Tensile modulus(ASTM D638) |

2500 MPa |

| fracture strain |

2% |

| curing temperature |

Between -35°C until 65°C |

| Setting time (at 25°C) |

5 day |

| Pot life (at 25°C) |

30 min |

Tips for Engineers Working with Epoxy Resin Saturant:

- Understand the properties and characteristics of the specific epoxy resin saturant.

- Follow the manufacturer’s instructions for

- handling, storage, and disposal.

- Wear appropriate personal protective equipment (PPE).

- Ensure proper ventilation in the work area.

- Prepare the surface properly before applying the saturant.

- Thoroughly and accurately mix the epoxy resin saturant.

- Apply the saturant evenly and consistently.

- Allow sufficient curing time before subjecting to stress.

- Regularly inspect and monitor the cured

- saturant for any signs of degradation.

- Keep detailed records of usage for quality control and future reference.

Tips for Contractors Working with Epoxy Resin Saturant:

- Familiarize yourself with the specific epoxy resin saturant and its properties.

- Have the necessary equipment and personal protective gear.

- Prepare the work area properly.

- Follow the manufacturer’s instructions for mixing the saturant.

- Apply the saturant evenly and uniformly.

- Consider curing time and environmental conditions.

- Regularly inspect the cured saturant for defects.

- Clean and maintain equipment and tools.

- Dispose of waste according to regulations.

- Keep records of saturant usage for reference.

Installation and Implementation of FRP:

Bedding:

- Prepare the bed by applying primer and FRP epoxy putty, then lightly sand the surface and clean it of any dust, oil, or contaminants.

- Impregnate the prepared substrate with saturated FRP epoxy resin.

Mixing Ratio:

- For two-component FRP epoxy adhesive, mix resin and hardener in a ratio of 100:13 (component A to component B).

- Mix component A (resin) gently and slowly at low speed (600 rpm) for 3 minutes using a mixer, ensuring no air is trapped in the resin.

- Carefully measure the weight ratio and add component B (hardener) to the resin.

- Mix gently at 600 rpm for 3 to 5 minutes to achieve a smooth and uniform consistency.

Impregnation of Resin on Surfaces:

- Using a nap roller or brush, apply the saturated resin onto the prepared surface.

- Dip the carbon or glass fabric into the saturated resin, place it on the surface, and use a roller to remove excess adhesive.

Note:

- Some fabrics may not require impregnation and can be applied directly to the surface.

- Using a nap roller or brush, apply a second layer of saturated epoxy resin to the fabric.

- If additional fabric layers are needed for reinforcement, repeat steps 1 to 3.

Guide to Quality Control for Epoxy Resin Saturant:

- Inspect incoming epoxy resin saturant for quality and verify packaging integrity.

- Store and handle the saturant according to the manufacturer’s guidelines.

- Follow proper mixing ratios and procedures for consistent results.

- Ensure appropriate adhesion to the substrate and perform adhesion tests if necessary.

- Monitor curing time and conditions for desired hardness and properties.

- Conduct visual inspections for defects and address them promptly.

- Keep detailed documentation of saturant usage, tests, and results.

- Seek feedback for continuous improvement and address any issues promptly.

technical documents

Photo Gallery

Technical documentation request

Frequently Asked Questions

What is epoxy adhesive?

Epoxy adhesives are a combination of two components, resin and hardener. In fact, the hardener acts as a catalyst in the resin. The hardening catalyst in the resin starts the curing process and then provides the stiffness and strength of the epoxy adhesive by exothermic chemical reaction. Epoxy adhesives adhere to most materials and establish strong joints with high mechanical properties.

What is the advantage of epoxy adhesives?

Epoxy adhesives can be characterized by high adhesion strength, high strength, high resistance to corrosion and chemical attacks, high heat resistance, high water resistance, compatibility and adhesion with most materials, high resistance to stable loads and ... pointed out.

What are the uses of epoxy adhesive?

Epoxy adhesives, due to their good mechanical properties, can be used for bonding, sealing or coating surfaces. Some applications of epoxy adhesives include fabrication of FRP composites, rebar planting, installation of FRP systems, installation of metal plates on concrete surfaces, as a bonding layer of restorative mortars to old concrete or bonding of old concrete to new concrete, repair of cracks by sewing And ... becomes.

How to use epoxy adhesive?

For better adhesion of epoxy adhesive to the desired surface, the surface must be free of any contamination such as grease, plaster, paint, etc. After preparing the surfaces, the epoxy adhesive components are mixed with the ratio specified in the datasheet provided by the manufacturer. After preparing the adhesive, it should be applied to the desired surfaces using a syringe or manually. Finally, the epoxy adhesive must be cured or cured under suitable temperature conditions and at a certain time in the datasheet.

Epoxy adhesives can be used in what ways?

Epoxy adhesives can be applied using methods such as manual lamination, spraying or robotic processes.

What are the physical specifications and packaging of epoxy adhesives?

Epoxy adhesives are a clear, clear liquid. Epoxy adhesives are packed in special buckets of 20 to 23 kg and are marketed.

What is the best temperature to use epoxy adhesives?

Warmer temperatures accelerate the reaction and colder temperatures slow down the reaction. Epoxy adhesives can be used at a temperature of 5 to 35 degrees Celsius. But the best performance is provided at a temperature of 24 to 30 degrees Celsius.

How to mix epoxy adhesive components?

To mix and prepare the epoxy adhesive, you must first mix the contents of container A for 1 to 2 minutes. Then add the contents of container B to container A, completely or in equal parts, and stir the mixture again using a mechanical mixer for 1 to 2 minutes.

What is the price of epoxy frp adhesive?

The price of frp epoxy adhesive is calculated per kilo unit. Due to market fluctuations, it is not possible to offer a single price per kilo of epoxy adhesive. For this purpose, for inquiries or detailed information about the price of epoxy adhesive, you can contact the numbers listed on the Fazir website.

How to prepare epoxy adhesive?

For epoxy adhesives, you can ask construction materials suppliers or reinforcement companies. Afzir retrofitting Company is one of the companies active in the field of design, consulting and supply of building reinforcement materials.

Be the first to review “Epoxy Resin Saturant (ERS200)”