PRODUCT DESCRIPTION

TRM™200 Concrete Repair Mortar is a high-quality, versatile product explicitly designed to repair and strengthen concrete structures. It belongs to the category of dry concrete mortars and offers exceptional performance in various applications.

This cement-based mortar is formulated to be self-leveling, ensuring easy and efficient application. When mixed with water, it forms a non-shrinking, highly cohesive compound that adheres strongly to both steel and concrete surfaces. This exceptional bonding capability makes it suitable for use in a wide range of structural repair projects, even in chemically attacked environments.

The TRM™200 Concrete Repair Mortar is engineered to provide optimal results in terms of durability and strength. It effectively underlays concrete and reinforces structures with thicknesses ranging from 10 to 100 mm, accommodating different project requirements. In cases where a coarser aggregate is used, increased thickness may be necessary for optimal performance.

One of the key advantages of TRM™200 is its versatility in temperature conditions. It can be utilized within a recommended temperature range of -10 to +30 degrees Celsius, making it suitable for use in both summer and winter applications. In warmer climates, it performs exceptionally well at temperatures between +17 and +30 degrees Celsius, while in colder environments, it remains effective at temperatures between -10 and +17 degrees Celsius.

TRM™200 Concrete Repair Mortar is known for its rapid drying properties, allowing for faster project completion. Additionally, its non-shrinking nature ensures that the repaired areas maintain their original volume and integrity, minimizing the risk of future damage.

With its excellent workability and reliable performance, TRM™200 Concrete Repair Mortar is ideal for professionals seeking a durable and efficient solution for concrete repair and strengthening projects.

Purchase price of TRM™200 Concrete Repair Mortar:

The price of TRM™200 Concrete Repair Mortar can vary depending on several factors, including location, quantity purchased, and supplier. As an advanced and high-quality concrete repair product, it offers excellent value for its performance and durability.

When considering the price of TRM™200, it is essential to consider its superior properties, such as self-leveling capabilities, non-shrinking formulation, and strong adhesion to steel and concrete surfaces. These qualities contribute to efficient and long-lasting repairs, reducing the need for future maintenance and saving costs in the long run.

Furthermore, while the initial investment in TRM™200 Concrete Repair Mortar may be higher than standard concrete repair materials, its outstanding performance and extended service life can provide significant cost savings over time. By effectively addressing structural issues and minimizing the need for frequent repairs, TRM™200 offers a cost-effective solution in the realm of concrete repair and strengthening.

Features

- No shrinkage

- High adhesion and cohesion

- Suitable for chemical environments

- Easy spreading on the surface

- Ease of use

Applications

- Repairing concrete structures

- Preparation of infrastructure for flooring

- Repair and restoration of concrete in road pavements, parking lots and bridges

- Repair of hydraulic structures and water transfer and purification facilities

- Repair and strengthening of structures, supports, bridge surfaces, main beams

- Repairing surfaces that cannot be worked by hand or mechanical means

- Repair and improvement of exposed concrete in underwater environments that are attacked by sulfate and chloride

- Filling and sealing joints of concrete and metal structures, supports, plates

- Stabilization of concrete elements in the foundation

Packaging

- 30 Kg bags

Colour

- Grey

technical specifications

|

Maximum size of filler |

2.5mm |

| Type of filler fiber |

polymer |

|

amount of shrinkage |

0.05% |

| Minimum compressive strength |

70N/mm2 |

|

Minimum tensile strength |

9 N/mm2 |

| Minimum cohesion strength |

2.5 N/mm2 |

|

Minimum sulfate resistance ratio (1 year) |

0.9% |

| density |

2100 kg/m3 |

TRM™200 Concrete Repair Mortar is designed to repair and strengthen damaged concrete structures. Its exceptional performance has attracted the interest of structural designers and supervisors. This mortar stands out for its ability to minimize the adverse effects of working in negative temperatures, making it a reliable choice even in challenging conditions. Furthermore, TRM™200 offers a cost-effective solution compared to alternative methods of repairing concrete and damaged surfaces, further adding to its appeal for construction projects.

Afzir Reinforcement Company advises against using this repair mortar for concrete and steel structures that are exposed to chemical attacks at negative temperatures. Additionally, when using the product within a temperature range of zero to -10 degrees Celsius, it is crucial to ensure that the target surface is free from frost and moisture at a water-flow level and is kept warm. To maintain the target surface’s warmth, infrared or heating lights are recommended. Furthermore, to prevent air entrapment, pouring the mortar from one corner is advised.

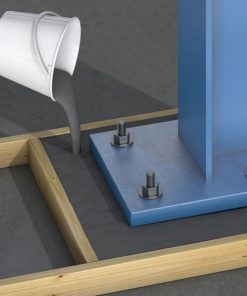

The installation procedure for this mortar follows several steps as outlined below:

Substrate Preparation:

To ensure strong adhesion of the mortar, begin by removing any damaged concrete. Use an appropriate tool to cut the damaged corners to a depth of 10 mm. Concrete demolition can be carried out using light guns or sandblasting. Additionally, clean any rusted reinforcements after removing the damaged concrete.

Installation of Dowel Bars:

In areas where the concrete strength is weak, it is recommended to install dowel bars according to the performance requirements of the masonry and concrete structure.

Moisturize:

Prior to application, thoroughly wet the entire surface to be restored with water. Afterward, remove any excess moisture using a cloth or compressed air.

Molding:

Use a sturdy mold made of durable materials capable of withstanding settlement and pressures that may occur during the repair process. Remove air trapped in cavities and vertical elements of the structure. Covering the mold surface in negative temperatures is important to prevent heat loss.

Mixing:

Combine 30 kg of dry powder with 3.45 liters of cold water (water temperature of +30°C is suitable, while hot water below +5°C is preferred for concrete durability). Use a mechanical mixer at high speed to mix the components for approximately 4 minutes.

By following these installation steps, you can ensure proper preparation and implementation of the mortar for effective concrete repair.

Sensitivity:

This product may cause sensitivity due to the presence of cement in its composition. Therefore, when working with the mortar, it is important to observe the following points:

- Wear gloves to prevent skin allergies.

- Use safety glasses to protect against eye irritation.

- Use appropriate protective clothing, gloves, and safety glasses in environments exposed to chemicals.

- Ensure the work environment is well-ventilated.

Skin Contact:

In case of skin contact, promptly wash the affected area with soap and water.

Eye Contact:

If the product comes into contact with the eyes, rinse immediately with plenty of water.

Breathing Difficulties:

If experiencing breathing problems during use, seek medical attention from a doctor.

Maintenance:

Storage:

Store the product in dry rooms with tight packaging, away from direct sunlight and humidity. The maximum air humidity should not exceed 70%.

Usage Duration:

When preparing the mortar, consider the limited usability duration, typically around 15 minutes. It is important to complete the application within this timeframe for optimal results.

By adhering to these safety precautions and maintenance guidelines, you can ensure a safe working environment and proper product storage, maximizing its effectiveness and longevity.

technical documents

Photo Gallery

Technical documentation request

Be the first to review “Pourable Polymer Modified Traffic Bearing Repair Mortar”