PRODUCT DESCRIPTION

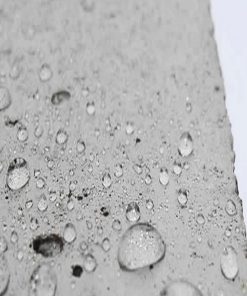

The WNCS™ nano water-repellent coating is a highly effective waterproofing material designed for building facades. It offers impermeability and dust-proofing properties to various natural and artificial stone types. Using nano technology, the coating comprises modified hydrophobic silane particles with a diameter ranging from 1 to 100 nanometers. This unique formulation enables the coating to cover the stone surface at a molecular or nanometer level.

When applied as a stone-faced waterproofing nano-coating, the entire surface of the stone benefits from enhanced hydrophobicity, dust-proofing, and impermeability. As a result, the stone is effectively protected against water penetration, chemicals, and natural pollutants. Damaging effects such as corrosion, scaling, weathering, freezing, fugue growth, and mold growth are significantly minimized. The durability and useful life of the stone coated with this nano waterproofing coating are greatly increased, reducing the need for frequent repairs or maintenance.

This type of facade waterproofing coating is primarily used for natural and artificial stones like marble, granite, and travertine in building facades. The application process for nano stone-faced water-repellent coatings, such as nano-firebrick insulation and nano-brick insulation, is simple and can be accomplished using common tools like sprays, brushes, or rollers. Its ease of application eliminates the requirement for specialized or skilled labor to perform the waterproofing operation.

Purchase Price of Nano Stone

The price of nano facade stone varies based on several factors, including the weight unit (kilogram) and market fluctuations. Additional considerations such as the materials used in the nano stone, country of manufacture, and brand influence price fluctuations. Due to these variables, providing a fixed price for WNCS™ hydrophobic nano-coating is impossible. To obtain accurate pricing information for nano stone-faced waterproofing or other protective coatings and sealing materials, we recommend contacting our experts at Afzir Retrofitting. They will provide professional advice and assist you in obtaining precise pricing details.

Features

- Suitable for all types of natural and artificial stone surfaces

- Based on nano technology

- Contains very fine nano particles with a diameter of 1 to 100 nm

- Water repellency

- Alcohol-based

- Keeping the surfaces clean due to reducing the penetration of pollution

- Ease of implementation

- Fast setting

- Resistant to environmental conditions

- Maintaining the breathability of the stone

- No change in the appearance of the stone

Applications

- Suitable for all types of natural and artificial stone surfaces, including marble, granite, travertine, etc.

Packaging

- –

Colour

- colorless

technical specifications

|

color |

colorless |

|

Shelf time |

12 months |

| Maintenance condition |

5-40℃ |

|

chemical basis |

Modified alkaline silane |

|

density |

0.85Kg/L |

| PH |

3-4 |

- Understand the Product: Familiarize yourself with the properties and limitations of the nano-coating.

- Conduct Surface Preparation: Ensure proper stone surface cleaning and preparation before application.

- Consider Compatibility: Assess the compatibility of the coating with the specific stone material.

- Follow Application Guidelines: Follow the manufacturer’s instructions for proper application techniques.

- Test and Monitor Performance: Conduct tests and monitor the coating’s effectiveness and appearance.

- Collaborate with Suppliers and Experts: Seek advice and insights from industry professionals.

- Consider Environmental Factors: Consider the environmental conditions the coating will face.

- Document and Communicate: Maintain thorough documentation and share information with stakeholders.

- Understand the Product: Familiarize yourself with the properties and limitations of the nano-coating.

- Training and Certification: Ensure your team is adequately trained and certified in applying nano coatings.

- Surface Preparation: Clean and prepare the stone surface thoroughly before applying the coating.

- Application Techniques: Follow the manufacturer’s recommended application methods and guidelines.

- Equipment and Tools: Use appropriate equipment and tools specified for the nano-coating application.

- Safety Measures: Implement safety protocols and use proper protective gear during the application.

- Quality Control and Inspection: Establish a process for quality control and conduct regular inspections.

- Ongoing Maintenance and Support: Provide clients with maintenance guidance and support for the coated surfaces.

- Collaborate with Suppliers: Maintain a good relationship with suppliers for assistance and expertise.

- Document and Warranty: Keep comprehensive records and provide clients with warranty information.

Surface Preparation:

Ensure the surface is free from contaminants like oil, dust, and paint. It must be scorched before applying the product.

Implementation Steps:

- Use WNCS™ coating as it is, without dilution.

- Apply the coating to the desired surface using spray, brush, or polish.

- Avoid reapplying the material if the surface has already dried.

- the surface is ready for use once the coating is dry.

Limitations:

- Do not reapply nanomaterials to the surface after application and drying.

- Ensure complete coverage and even distribution of materials on the surface.

Product Storage:

- Store in dry places.

- Keep the container covered and dry in the environment.

- Store within a temperature range of 5 to 40 degrees Celsius.

- Avoid freezing the product.

- Seal the container tightly after each use.

- The product’s shelf life is a maximum of 1 year.

- Documentation: Maintain thorough records of quality control processes.

- Standard Operating Procedures (SOPs): Develop and follow SOPs for quality control.

- Visual Inspection: Check for visual defects and ensure uniform coating application.

- Adhesion Test: Assess bonding strength between coating and stone surface.

- Water Repellency Test: Verify the effectiveness of coating in repelling water.

- Durability Assessment: Evaluate the coating’s resistance to environmental conditions.

- Thickness Measurement: Measure coating thickness to meet specifications.

- Compatibility Testing: Test for adverse reactions on a small area before completing an application.

- Performance Evaluation: Monitor the long-term performance of coated surfaces.

- Calibration and Maintenance: Regularly calibrate and maintain testing equipment.

- Training and Expertise: Ensure personnel are trained and knowledgeable in testing methods.

- Continuous Improvement: Continuously improve processes based on feedback and advancements.

technical documents

Photo Gallery

Technical documentation request

Be the first to review “Water Repellent Nano Coating for Stone”