PRODUCT DESCRIPTION

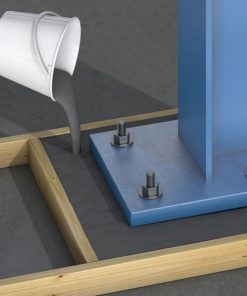

Self-leveling cement mortar is a versatile and innovative solution used to create a smooth and level surface, particularly for flooring applications. This specialized mortar is designed to overcome the challenges posed by uneven or damaged substrates, such as concrete with slopes, holes, or depressions. By utilizing various additives, including lubricants, shrinkage reducers, thickeners, and bubble-forming agents, self-leveling cement mortar achieves exceptional leveling properties and ensures a uniform finish.

The self-leveling nature of this mortar eliminates the need for extensive manual leveling, saving time and effort during installation. It effortlessly fills in gaps, voids, and irregularities in the substrate, resulting in a seamless and flawless surface. With a leveled sub-floor, the installation of new flooring becomes significantly easier, ensuring proper adhesion and extending the longevity and aesthetics of the finished floor.

One of the notable advantages of self-leveling cement mortar is its rapid drying time. Within approximately 4 to 6 hours, the mortar dries completely, allowing for faster progress in the project. This expedited drying process reduces downtime, enabling quicker access to the treated area.

Suitable for a wide range of surfaces, including concrete, wood, and ceramics, self-leveling cement mortar offers exceptional versatility. Its compatibility with different substrates makes it an ideal choice for various flooring applications, whether it be residential, commercial, or industrial settings.

Furthermore, self-leveling cement mortar requires minimal water for mixing, enhancing its resistance properties. This characteristic improves the overall durability and strength of the mortar, ensuring a long-lasting and robust flooring system.

As a reputable supplier of self-leveling cement mortar, Afzir Company takes pride in delivering high-quality products that meet industry standards. Our experts possess extensive knowledge and experience in the field, enabling them to provide professional guidance and support throughout your project. For more information, pricing details, or to purchase self-leveling cement mortar, we encourage you to contact our dedicated team at Afzir. Experience the benefits of this innovative solution and achieve exceptional results in your flooring projects.

Features

- Polymer-based modified mortar

- Self-alignment and high psychological properties

- Applicable for thicknesses ranging from 1.5 mm to 38 mm

- High compressive strength

- Good adhesion to all types of substrate surfaces

- One-component mortar, ready to use

- Resistant to wear and moisture

- Easy implementation, no troweling required

- Reasonably priced self-leveling mortar

Applications

- Self-leveling floor of all types of concrete surfaces

- To implement all types of flooring

- Repairing damaged concrete floors, including all types of industrial floors and…

- Application of self-leveling mortar on old ceramics

- To level the floor under tile carpets

- As a micro cement for the floor in an integrated and seamless manner

Packaging

- 25 kg bags

Colour

- Gray

technical specifications

| Physical state |

powder |

| color |

grey |

| PH |

11 |

| density |

2.06Kg/L |

| setting time |

3-24 hours |

| Operating temperature |

10 to 29 ℃ |

|

compressive strength (7 days) |

21.7MPa |

| compressive strength (28 days) |

28.6MPa |

|

flexural strength (28 days) |

7.38MPa |

- Surface preparation: Thoroughly clean and prepare the substrate before application.

- Follow manufacturer guidelines: Adhere to the recommended mixing ratios, curing times, and application techniques specified by the manufacturer.

- Test compatibility: Perform a small-scale compatibility test to ensure proper bonding with the substrate.

- Consider temperature and humidity: Take into account the specified conditions during application and curing.

- Use proper tools: Utilize appropriate tools for mixing and application as recommended by the manufacturer.

- Monitor thickness: Maintain the specified thickness range during application for desired leveling.

- Plan for curing time: Allow sufficient time for the mortar to cure before subjecting it to foot traffic or further construction activities.

- Seek professional assistance if needed: Consult experienced engineers or the manufacturer’s technical support team for complex projects.

- Perform quality checks: Regularly inspect and conduct quality checks to ensure proper application and adherence to standards.

- Prioritize safety: Adhere to safety protocols and use appropriate personal protective equipment (PPE) during application.

- Familiarize with product specifications: Understand the mixing ratios, application thickness, and curing times provided by the manufacturer.

- Proper surface preparation: Ensure a clean, debris-free, and structurally sound substrate before applying the mortar.

- Test compatibility: Conduct a small-scale compatibility test to ensure proper bonding with the substrate.

- Use the right tools and equipment: Utilize recommended tools for mixing and application to achieve consistency.

- Maintain a consistent mixing process: Follow the manufacturer’s instructions for proper water-to-mix ratio and mixing time.

- Efficient application: Plan the application process to work within the specified working time of the mortar.

- Monitor thickness and leveling: Regularly check and adjust the thickness of the applied mortar to achieve desired levelness.

- Allow proper curing time: Give sufficient time for the mortar to cure before subjecting it to traffic or construction activities.

- Perform quality checks: Inspect during and after application to ensure adherence to standards and address any issues promptly.

- Seek technical support if needed: Consult the manufacturer’s technical support or experienced professionals for complex projects.

Mixing:

For each bag of leveling mortar (25 kg), mix it with 6.2 liters of water. Follow the manufacturer’s instructions for the specific mixing process.

Surface Preparation:

Ensure the work surface is properly prepared, clean, and free from any contaminants or debris.

Spreading the Mortar:

Using a trowel, spread the self-leveling polymer mortar onto the prepared surface. Spread it evenly to achieve the desired thickness. Work in sections if necessary.

Second Layer (if needed):

If additional layer is required or desired, you can apply a second layer of mortar. Wait for 24 hours after the first layer is applied before applying the second layer.

Finishing:

Once the mortar is applied, use a trowel or smoothing tool to ensure a smooth and level finish. Pay attention to any edges or corners for a seamless transition.

Curing and Drying:

Allow the self-leveling mortar to cure and dry according to the manufacturer’s instructions. Follow the recommended curing time before subjecting the floor to foot traffic or further construction activities.

Note: It is important to refer to the specific instructions provided by the manufacturer of the self-leveling polymer mortar (Code 200™ SLM) for precise mixing ratios, application techniques, and curing times.

- Follow the manufacturer’s instructions for mixing ratios, application thickness, and curing times.

- Ensure proper surface preparation and substrate cleanliness.

- Mix the mortar according to the manufacturer’s instructions using suitable equipment.

- Monitor and maintain the desired thickness during application, achieving even and consistent leveling.

- Verify good adhesion between the mortar and the substrate, conducting adhesion tests if necessary.

- Allow sufficient time for proper curing and drying before subjecting the mortar to foot traffic or construction activities.

- Conduct regular inspections to identify and address defects, inconsistencies, or non-conformities.

- Maintain detailed records of quality control activities, including deviations, corrective actions, and observations.

- Continuously improve the quality control process based on feedback and lessons learned.

- Foster effective communication and collaboration among project stakeholders to optimize quality control.

By following these guidelines, contractors can ensure effective quality control for One-Component Self-Leveling Mortar (Code 200™ SLM), resulting in consistent and high-quality flooring projects.

technical documents

Photo Gallery

Technical documentation request

Be the first to review “One-Component Self-Leveling Mortar”