PRODUCT DESCRIPTION

Fiberglass mesh is used to reinforce various surfaces in different types of buildings. This mesh strengthens the damp-proof course for slabs and ceilings and supports unstable external surfaces and aiding in crack prevention. The mesh is made from glass fiber strands that provide exceptional strength when placed in a wet base layer. Fiberglass mesh is also used for creating mechanically strong filler coatings with unique properties.

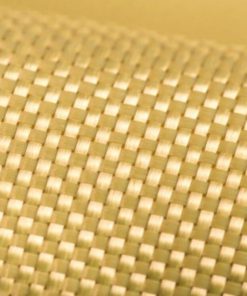

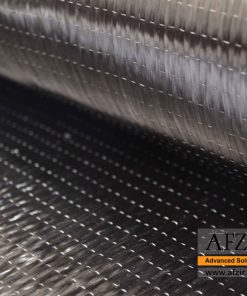

Fiberglass mesh belongs to the category of FRP meshes. It is made from C or E-type glass fibers (silicate-based materials with good chemical stability) using a specific weaving technique. After surface treatment, this fiberglass mesh exhibits excellent alkaline resistance and outstanding properties such as water resistance, alkaline resistance, flexibility, softness, and resistance to deterioration. It is widely used to reinforce walls, natural marble, plasterboard, artificial stone materials, and exterior insulation systems.

Reasons for choosing fiberglass reinforcing mesh in buildings:

- Fiberglass mesh has excellent resistance to acids, alkaline substances, and other chemicals and performs exceptionally well in reinforcing various building surfaces.

- Fiberglass mesh has high tensile strength. Therefore, reinforcing wall plastering or cementing uniformly disperses external and internal stresses in the wall system, preventing damage.

What are the advantages of fiberglass mesh?

- It prevents the occurrence of cracks due to its good resistance to chemical corrosion and high tensile and weft strength.

- Distortion in the system resulting from heavy impact is minimized as stress is evenly distributed in different directions.

- High-strength fiberglass mesh fabric can reinforce and protect the stone. It can easily be applied on the back of marble, mosaic, and stone surfaces.

What is an anti-crack fiberglass mesh?

Cracks on the surface of concrete and various other spaces can pose numerous problems for a structure. Cracks caused by earthquakes and vibrations can have even more significant risks. This is where the role of a vibrant glass fiber mesh becomes more prominent. Anti-crack fiberglass is one type of mesh that can be used to address cracks due to its unique structure and physical properties.

These meshes are made from the same glass fibers and have a similar structure to a fiberglass mesh. However, to enhance the elasticity of these meshes, a particular layer of additives is applied to their outer surface, which significantly affects the improvement of their mechanical properties.

With these additives in the structure of the mesh and fiberglass, they can be used for strengthening various spaces. One of the advantages of an anti-crack fiberglass mesh is its high resistance to alkaline environments. Additionally, these meshes are highly resistant to weather conditions, moisture, sudden and gradual temperature changes, and more. Therefore, they can efficiently act as a preventive measure against various building cracks. Ultimately, it can be said that an anti-crack fiberglass mesh is a special type of mesh that, due to its good mechanical properties, can contribute to the reinforcement of structures and buildings.

What is fiberglass stone lace?

One of the applications of fiberglass mesh is using behind stones. Due to their specific application, these meshes are also known as fiberglass stone backing meshes. These meshes comprise thin composite threads made of glass fibers and polymers. The use of stone lace meshes is highly significant for reinforcing building stones. Therefore, in most factories producing building stones, these meshes are placed behind the stones using epoxy resins.

The advantage of using stone lace meshes is increasing the physical strength of these stones. Additionally, these meshes enhance the adhesion of stones during their building installation. They also help reduce the risk of stone breakage due to sudden impacts. Furthermore, these meshes increase the resistance of stones to various chemicals and conditions. Therefore, many factories utilize these meshes for their stones.

What is a Wall Post with fiberglass mesh?

In fact, the most crucial purpose of implementing Wall Posts in buildings is to prevent the destruction of walls during earthquakes. By increasing the free span of walls, Wall Post enhances their resistance to the loads generated by earthquakes. Therefore, cracks may appear on the wall during an earthquake, but this is not a concern because the wall post can significantly increase structural resistance.

In general, Wall Posts can be made from various materials. However, in recent years, the engineering system has developed a new code for implementing Wall Posts. According to this code, fiberglass mesh should be used as the wall post in buildings. Therefore, a Wall Post is one of the applications of fiberglass mesh used to increase the structural resistance to earthquakes.

It is important to note that according to engineering regulations, the fiberglass mesh used as a Wall Post should weigh 110 grams. If the weight of the fiberglass mesh Wall Post is less, the structural safety will not be acceptable. Therefore, builders should not purchase lighter fiberglass meshes for building use to reduce costs.

Interestingly, fiberglass mesh can also be used as an efficient, innovative Wall Post.

Fiberglass Mesh Waterproofing (Damp-proof):

One of the most important considerations for preventing damage to structures exposed to moisture is the insulation of these structures. Insulating walls, swimming pools, and other elements should be done using appropriate methods. Although there are various techniques for waterproofing and sealing pools, one of the best methods is using fiberglass mesh for waterproofing and moisture insulation.

Fiberglass mesh waterproofing, or fiberglass moisture barrier, is made from glass fibers. As you may know, these fibers have good resistance to moisture and will not easily deteriorate. However, to enhance the resistance of these fibers to moisture, a layer of resin is also applied to the fiberglass mesh, which can improve the waterproofing conditions of these meshes.

Due to their lightweight and affordable price, fiberglass mesh waterproofing can be used for various structures, including pools, walls exposed to moisture, and more. These meshes have a very long lifespan, so even after the demolition of the structure or pool, there will be no need to replace the fiberglass meshes.

If different materials and chemicals are present in the structure exposed to water and moisture, the best waterproofing solution is using fiberglass mesh. These meshes have high resistance to chemical substances. Another advantage of these meshes, which enhances the safety of moist structures, is their suitable electrical insulation property. Therefore, these meshes can be used to prevent the entry of electrical current into structures and avoid electrical conductivity.

Features

- Use of E-glass fibers in mesh production

- Variety in mesh spring and weight

- High electrical resistance

- High flexibility

- High compressive and tensile strength

- Lightweight

- Easy application

- Affordable price and high cost-effectiveness

- Suitable for various architectural elements with different shapes and dimensions.

Applications

EFMTM fiberglass mesh is known as a widely used product in the construction industry due to its features such as long life in addition to strength and resistance.

- Use in FRCM composite system to strengthen the building

- Strengthening and stabilizing sealing and insulation in pools, reservoirs, etc.

- Stabilization of walls

- Furniture industry

- A good alternative to metal mesh under the roof

- Stabilizing the facade of the building and creating a suitable platform for installing tiles, mosaics, etc.

- Wall stabilization using the innovative method of Wall Post

- Plastering and cementing walls with fiberglass mesh.

- Enhancing the adhesion of building stones

Packaging

- Available in different sizes and weights

Colour

- White

technical specifications

|

specification |

E-fiberglass mesh |

|

Weight per unit area |

80-200 g/m2 |

| color |

white |

|

Mesh size |

5*4 4*5 7*9 10*10 |

Refer to the technical data sheet of the product.

- Understand the properties of E-glass mesh.

- Handle and store E-glass mesh properly.

- Prepare the surface before applying the mesh.

- Choose the appropriate adhesive for bonding.

- Follow proper installation techniques.

- Overlap and reinforce the mesh as needed.

- Conduct regular inspections for damage or improper adhesion.

- Follow manufacturer guidelines and specifications.

- Consider environmental factors that may affect performance.

- Seek professional advice if needed.

- Familiarize yourself with E-glass mesh and its applications.

- Ensure proper handling and storage of the mesh to prevent damage.

- Prepare the substrate surface thoroughly before installing the mesh.

- Use the appropriate adhesive or mortar for securing the mesh.

- Follow the manufacturer’s guidelines for installation techniques and overlaps.

- Inspect the mesh for any damage or improper adhesion.

- Consider the environmental conditions during installation for optimal performance.

- Train your team on proper installation techniques and safety measures.

- Communicate and coordinate effectively with other trades involved in the project.

- Maintain accurate documentation of installation processes and materials used.

- The working surface should be clean and free from any contamination. A grinding machine should remove old layers, oil, organic materials, and dust.

- Prepare the reinforcing mortar and uniformly spread it on the surface using a trowel.

- Immediately place the E-glass mesh on the moist surface, ensuring it covers a wide area.

- Smooth the mesh using a metal trowel from the center towards the edges. The adequately applied mesh should not be visible and should be fully embedded in the mortar.

- It is essential to maintain overlaps of approximately 10 centimeters with the next applied mesh strips.

- In the presence of corner holes in the walls (e.g., windows), it is recommended to embed additional mesh sections with dimensions of about 20 by 30 centimeters at an angle.

The work surface must be clean and free of any contamination. Old layers, oil, organic matter and dust must be removed by grinding machine. First, the prepared reinforcing mortar should be spread evenly on the surface with a trowel. In the prepared layer, immediately spread the fiberglass mesh on the wet surface, then use a metal trowel to smooth it from the center to the edge of the mesh. A properly applied mesh should not be visible and should be completely embedded in the mortar. It is important to keep the lace overlaps on the next applied straps up to about 10 cm. If there are corner holes in the walls (for example, windows), it is recommended to install additional parts of the mesh with dimensions of about 20 x 30 cm diagonally.

technical documents

Photo Gallery

Technical documentation request

Frequently Asked Questions

What is the use of fiberglass net and mesh?

Reinforcing fiberglass mesh is ideal for use in building construction, mainly for reinforcing concrete, cement, flooring, rendering, covering drywall joints, cracks and holes in drywall, plasterboard, plastering and other levels are used.

What is the feature of fiberglass mesh?

Fiberglass mesh has features such as flexibility, proper adhesion, high tensile strength, electrical resistance, etc.

What is the unit weight of n fiberglass mesh?

The unit weight of fiberglass mesh is 80 to 200 grams per square meter.

What is the thermal resistance of fiberglass E?

-70 to 550 degrees Celsius

What is the advantage of fiberglass mesh compared to steel mesh?

Low specific weight at the same time high tensile strength.

Be the first to review “E-Glass Fiber Mesh”