PRODUCT DESCRIPTION

What is Carbon Fiber Laminate?

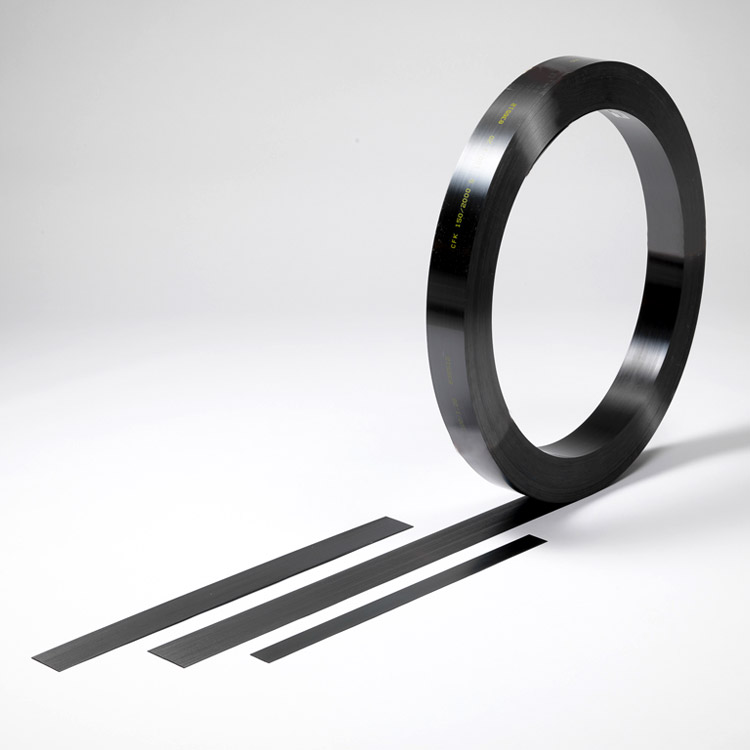

Afzir Carbon Fiber Laminate Sheet comprises carbon fibers arranged in an epoxy resin matrix. The materials are carefully molded and hardened to create plates for reinforcement and retrofitting in engineering and construction projects.

Pre-processed FRP carbon laminate is manufactured in factories to ensure higher quality and uniformity than other products. This is achieved through a higher fiber-to-resin ratio, resulting in increased strength and hardness during wet layering. The prefabricated carbon laminate is typically produced with a width of 50-100 mm and a thickness of approximately 1.3-1.4 mm. During installation, these laminated tapes are bonded to the outer surface of structures using an epoxy resin adhesive.

Carbon laminate sheets are made from carbon fibers that possess four times the tensile strength of steel. These products have a tensile strength exceeding 2400 MPa and are available in rolls with a length of 100 meters. Carbon laminate sheets are suitable for unique applications previously challenging conventional wet layering systems. They find usage in cases where high strength and low weight are critical, ranging from drones to car and motorcycle parts.

Critical Properties of Carbon Fiber

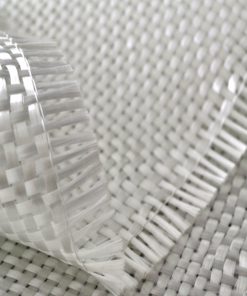

We focus on producing high-quality products that deliver exceptional performance in demanding conditions. Carbon fiber sheets, in general, exhibit high resistance to continuous loads and perform well against tensile, compressive, and flexural forces. They also demonstrate excellent performance in plate shear and interlaminar shear. Carbon fiber sheets offer superior tensile strength, flexural modulus, heat distortion temperature, and linear expansion compared to other epoxy laminates. The woven layers of pure carbon fiber bonded with hard plastics like epoxy resin make carbon laminates exceptionally strong. Additionally, unidirectional carbon fiber sheets’ maximum tensile and flexural strength align along a specific axis.

Pultrusion Carbon Fiber Laminate (CFRP) for Structural Reinforcement

Carbon laminate is a rigid polymer reinforced with polyurethane carbon fiber to strengthen concrete, masonry, steel, and wood structures. The CFRP laminate acts as an external support element, bonded to the substrate using FRP tape epoxy adhesive.

Why Consider Carbon Fiber Sheets in the Automotive Industry?

As we know, carbon laminate exhibits high strength and lightweight characteristics, making it highly beneficial in reducing the weight of vehicles, enhancing body strength, and lowering fuel consumption. Therefore, using carbon fiber sheets in automobiles can lead to significant advancements and energy savings, which have far-reaching societal implications.

The adoption of FRP carbon laminate in the automotive industry is expected to experience substantial growth.

Four Key Advantages of Carbon Fiber Sheets in Automotive Applications:

- Weight Reduction

- Enhanced Aesthetics

- Improved Durability and Longevity

- Increased Vehicle Safety

Carbon Fiber Sheet Pricing

The global market value of carbon fiber composites is projected to rise from $70.4 billion in 2020 to $112.8 billion by 2025. Composites exhibit exceptional properties such as hardness, strength, adhesion, thermal and electrical conductivity, fatigue, and corrosion resistance. These outstanding properties have led to the preference for composites over conventional materials like steel and aluminum in high-performance industrial applications.

In terms of carbon fiber sheet prices, carbon fiber composites are experiencing the fastest growth among fiber composites. Carbon fiber composites are expected to dominate in value between 2020 and 2025. Carbon fiber is twice as strong and 30% lighter than fiberglass and traditional fibers. Its utilization is anticipated to persist in various industries for a significant period.

Key Features

- High tensile strength

- Corrosion resistance

- Low dead weight at building height

- Customizable length delivery (no need for overlapping)

- Excellent fatigue behavior

- Easy, flexible, and cost-effective technology

- Simple installation at intersections

- Sound and vibration-free installation.

Applications

- Strengthening and increasing shear and flexural strength in ordinary concrete structures.

- Enhancing the rigidity and overall strength of various structures.

- Reinforcing pre-stressed reinforced concrete elements.

- Strengthening building material structures.

- Enhancing the strength of wooden structures.

- Controlling and preventing cracks in the plastic area of structural members.

Packaging

- Width 50-100 mm

- Thickness 1.2-1.4 mm

Colour

- black

technical specifications

| specification |

CFRP Laminate |

|

Design area |

140mm2 |

| Laminate thickness |

1.4mm |

| width |

100mm |

| Tensile strength |

2400MPa |

| Tensile modulus |

131GPa |

| elongation |

1.87% |

| Fiber volume fraction |

70% |

| Matrix type |

Polyester resin |

- Understand the material’s properties and behavior.

- Assess structural requirements before selecting the material.

- Optimize design to maximize benefits.

- Follow proper installation procedures and guidelines.

- Consider compatibility with other materials.

- Implement quality control and testing measures.

- Collaborate with experts in the field.

- Stay updated with technology and industry standards.

- Evaluate cost-effectiveness.

- Prioritize safety throughout the project.

Contractor Requirements:

Only trained and approved contractors should install the unidirectional FRP carbon laminate.

Following these instructions will help ensure the proper installation and performance of unidirectional carbon laminate in your project.

- Familiarize yourself with the material.

- Collaborate with engineers and designers.

- Provide adequate training for your team.

- Follow manufacturer guidelines for installation.

- Implement a robust quality assurance process.

- Prioritize safety throughout the project.

- Maintain open communication and coordination.

- Consider project-specific requirements.

- Document the installation process.

- Continuously update knowledge and skills.

Surface Preparation:

- Ensure the surface is clean, dry, and free from water, frost, dust, dirt, oil, and debris.

- Prepare the surface by methods like light sandblasting or milling.

- Fill large voids with repairing mortar.

- Check the substrate adhesion using a pull-off test under the supervision of an engineer.

Cutting the Carbon Laminate:

- Use heavy scissors, a reciprocal saw, or similar tools to cut the FRP carbon laminate to the appropriate length.

- Take care to prevent tearing of the laminate at both ends.

Implementation and Application:

- Apply an epoxy primer coating to the substrate.

- Clean the worn side of the tape with acetone or similar solvents, ensuring the removal of foreign contaminants. Allow the solvent to evaporate for at least 30 minutes.

- Apply a minimum 1.5 mm thick layer of epoxy adhesive to the cleaned part of the FRP tapes.

- Allow the epoxy to reach its maximum viscosity.

- Install the laminate tape system according to the specified curing time of the epoxy adhesive, ensuring even application for optimal performance.

- Use a rubber roller to firmly press the laminate onto the epoxy adhesive, ensuring the glue comes out on both sides.

Inspection of Incoming Materials:

- Verify the quality and specifications of the unidirectional carbon laminate materials upon delivery.

- Check for any damage, defects, or deviations from the required standards.

- Ensure that the materials are appropriately labeled and identified.

Surface Preparation Evaluation:

- Assess the adequacy of surface preparation before installing the carbon laminate.

- Verify that the surface is clean, dry, and free from contaminants.

- Check if proper methods, such as sandblasting or milling, were employed for surface preparation.

Adhesive Quality Assessment:

- Inspect the quality of the epoxy adhesive used for bonding the carbon laminate.

- Ensure that the adhesive meets the specified requirements, including viscosity and curing properties.

- Perform tests or checks to verify the adhesion strength of the laminate to the substrate.

Laminate Installation Inspection:

- Monitor the installation process to ensure proper alignment and positioning of the carbon laminate.

- During installation, check for visible defects, such as bubbles, wrinkles, or delamination.

- Ensure the laminate is securely bonded to the substrate with proper contact and adhesion.

Thickness and Dimensional Measurements:

- Conduct measurements of the thickness and dimensions of the installed carbon laminate.

- Verify that the measurements comply with the specified requirements and tolerances.

- Use appropriate tools and techniques for accurate measurements, such as calipers or laser measuring devices.

Non-Destructive Testing:

- Consider performing non-destructive testing methods, such as ultrasound or thermal imaging, to assess the integrity and uniformity of the laminate.

- Detect any hidden defects or inconsistencies that may affect the performance of the carbon laminate.

Adherence to Standards and Specifications:

- Ensure the installation and quality control procedures adhere to relevant industry standards, guidelines, and project specifications.

- Regularly review and cross-reference the applicable standards to verify compliance.

Documentation and Record-Keeping:

- Maintain detailed records of quality control inspections, tests, measurements, and deviations or corrective actions.

- Record the materials used, suppliers, and relevant certifications for traceability and future reference.

Regular Quality Audits:

- Conduct periodic quality audits to assess the overall quality control processes and identify areas for improvement.

- Involve qualified personnel to perform independent evaluations and reviews.

Continuous Training and Improvement:

- Provide ongoing training and education to personnel involved in unidirectional carbon laminate quality control.

- Stay updated with industry advancements, new testing methods, and best practices to improve the quality control process continually.

By following this guide to quality control, you can ensure the consistent and reliable performance of unidirectional carbon laminate in your projects..

technical documents

Photo Gallery

Technical documentation request

Frequently Asked Questions

What is FRP carbon sheet or laminate?

FRP sheet or laminate is made of a combination of several layers of unidirectional or bidirectional fiber fabric made of carbon fibers, glass, etc., along with epoxy resin, polyester, vinyl ester, etc. FRP sheets are marketed in different dimensions and thicknesses depending on the intended application. FRP sheets or laminates, due to their light weight, have several times more mechanical properties than steel, aluminum and other materials. For this purpose, FRP laminates are widely used in the implementation of reinforcement designs.

How to use carbon sheets and laminates?

To install laminates made of carbon fiber, the surface must first be cleaned of any contamination. Then the FRP laminates should be cut according to the dimensions stated in the reinforcement design plan, using a saw, and finally, using epoxy resin, to the desired surface.

What are the uses of Frp carbon sheet or laminate?

Frp sheet or laminate is widely used in various industries such as construction, aerospace, medical equipment, sports products, etc. Frp laminate is commonly used in the construction industry to improve and enhance the mechanical properties of structural elements.

What are the characteristics of Frp carbon sheet or laminate?

Features of carbon sheet include high flexural and shear strength, low weight, impermeability, high stability and durability, compatibility with most materials, long service life, ease of installation, high resistance to corrosion, high resistance to heat pointed out.

At what temperature can carbon sheets and laminates be stored?

Carbon sheets and laminates should be stored in a dry place at 4 to 40 °C.

What should be observed when applying carbon sheets and laminates?

Approved personal protective equipment should always be available. The mask is recommended to prevent airborne particles (particles from cutting fibers) from entering the lungs and gloves to prevent skin irritation when handling fabric and resin. Eye shield is recommended to prevent eye irritation. The ventilation system must be completely standard and in the absence of proper ventilation, the use of a respirator is mandatory.

What measures should be considered to clean surfaces impregnated with laminate resin materials?

Dried materials can be cleaned with approved solvents. But the dried material can only be disposed of mechanically, the material must be disposed of in accordance with waste disposal regulations.

What is the standard temperature for best results from sheet metal and carbon laminating?

For best results from installing carbon sheets and laminates using laminate resin, it should be done at a temperature of 5 to 30 degrees Celsius.

What is the price of Frp carbon sheet or laminate?

Frp sheets and laminates are usually sold in the market on a unit length basis. The price of Frp laminates is priced based on the dimensions, thickness and type of resin used in the sheet production process. It is not possible to offer a single price due to fluctuations in the market. For this purpose, for detailed information and inquiries about the price of Frp laminate, you can contact our sales experts in Afzir company.

How to make Frp carbon sheet or laminate?

To prepare carbon sheet or Frp laminate, you can apply through suppliers of building materials or suppliers of materials needed to implement reinforcement projects. Afzir Company is one of the active groups in the field of consulting, design, implementation and supply of products required for building retrofitting.

Be the first to review “Unidirectional Carbon Laminate”