FRP Bar Versus Steel Bar

Steel bar or reinforcement is used to compensate for the low tensile strength of concrete. The bar is used in various reinforced concrete members. Steel bars that are used to reinforce concrete structures do not have high corrosion resistance and, in a corrosive environment, damages will occur in the structure. Thus, a kind of rebar, called FRP rebar, has been introduced since the advent of FRP products, which, in addition to its durability and long life, is resistant to corrosion and can increases the strength of the structure. In a superficial comparison between steel and FRP rebar, one can say:

- The specific weight of steel bars is 7.75 grams per cubic centimeter and the weight of FRP rebar is about 2.2 grams. FRP bar is much lighter than steel bar. Due to this low density, the cost of transport and displacement of FRP rebar is less. Also, the dead load of the structure will be less than that of steel bars.

- One of the disadvantages of steel bars is their low resistance against chemicals and corrosion, which reduces the resistance of concrete sections. FRP rebar reinforce the structure and protect it from corrosion.

- The total prices of FRP rebar is lower than that of steel bars.

FRP Composite Rebar

FRP rebar is a composite product that replaces steel bar and significantly reduces the damage caused by corrosion of rebar in corrosive and acidic environments. The use of FRP rebar is the best option for reinforcing concrete in places where the concrete has to be in contact with electrical and magnetic fields. FRP rebar can also be used to design and build new buildings. FRP rebar, with its favourable properties, reduces the diameter and increases the distance between bars in reinforced concrete members, such as slabs, tunnels, foundations, etc. Also, FRP rebar will increase the damping induced in the structure against earthquake-induced vibrations or industrial equipment and will be the best option for increasing the strength of the structure against earthquake or vibration and retrofitting structures.

FRP composite rebar fundamentally consist of two parts of FRP fibers and resin. The behavior of both fibers and resin is effective in the final behavior of FRP rebar. Based on the type of resin, which can be selected among a variety of polyester, epoxy or vynil-ester, and the type of fibers that can be carbon, glass fiber, aramid fiber types, there are three types of FRP composite rebar in markets. FRP bar classification is performed according to the fibers used in the polymer:

- Glass Fiber Reinforced Polymers Rebar (GFRP Rebar)

- Carbon Fiber Reinforced Polymers Rebar (CFRP Rebar)

- Aramid Fiber Reinforced Polymers Rebar (AFRP Rebar)

The GFRP rebar are the less expensive and most popular FRP rebar. There are a lot of concrete structures that are reinforced with GFRP rebar, all around the world.

FRP Composite Rebar Application

FRP rebar or FRP composite rebar are an appropriate replacement for steel bars in corrosive environments. These bars are made by combining FRP fibers and a resin matrix. For this reason, they are also referred to as FRP composite reinforcement. The price of FRP composite rebar is low compared to steel bars and the properties that the user receives from them. Because if the user wants to receive the same properties from steel bars, it should be several times higher than the price of FRP rebar. FRP bars significantly reduce the damage caused by corrosion of steel rebar in corrosive and acidic environments. The use of FRP rebar in places in vicinity of electrical and magnetic fields is the best option for arming concrete. FRP reinforcing bars can also be used to design and build new buildings. The excellent properties of these materials lead to reduce the diameter of bars and increase the distance between the bars in armed reinforced concrete members.

Among the bars above, Fiberglass or GFRP rebar is the cheapest reinforcement rebar.

FRP Rebar Properties

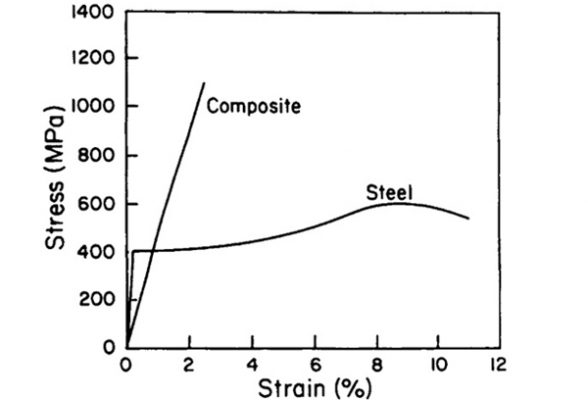

The behavior of FRP composites is completely elastic. This elastic behavior continues until it’s broken. As mentioned, the resistance of FRP composite reinforcements is much higher than steel. With this in mind, their elastic strain is much more than steel. This causes all the deformation occurring in the FRP composite bars to be reversible. The modulus of elasticity or elastic modulus of FRP composite rebar varies depend on the fibers and the resin.

The sizes of various FRP composite rebar (CFRP rebar and GFRP rebar) are given in the table below:

| rebar size | actual diameter (mm) | cross section (mm2) |

| 6 | 6.4 | 6.31 |

| 10 | 9.5 | 71 |

| 13 | 12.7 | 129 |

| 16 | 15.9 | 199 |

| 19 | 19.1 | 284 |

| 22 | 22.2 | 387 |

| 25 | 25.4 | 510 |

| 29 | 28.7 | 645 |

| 32 | 32.3 | 819 |

| 36 | 35.8 | 1006 |

FRP Rebar Advantages

Resistance to electrical current

FRP Composite Rods are non-conductive and prevent the conduction of electrical current. For this reason, this type of rebar is used in building construction of structures that are likely to be in contact with electrical current. The use of FRP bars to prevent electrical current includes: the construction of concrete towers for the transmission of power, the construction of beams, prefabricated posts, and so on.

Resistance to corrosion, acids and bases

Epoxy resins used in the production of FRP composite rebar are extremely resistant to chemicals such as acid, salt and water, and prevent corrosion of rebar. Due to the high strength of these bars, they are used to construct structures exposed to ice-stopping salts. In addition to the construction of marine structures, decks of bridges and berths are also used.

Strengthening and reinforcement of concrete structures

The corrosion phenomenon in concrete reinforced with steel rebar is due to this fact that the steel bars inside the concrete start to rust and oxidize. These oxides are then released inside the concrete and cause the loss of concrete. Thus, the concrete structure is completely destroyed by the ingress of rebar and concrete. The use of FRP rebar, due to its high strength and anti-corrosion properties, leads to strengthening of concrete structures.

Light weight (no additional load on the structure)

The density of the FRP rebar is low, and this lowers the weight of the bars and prevents the load from overloading the structure.

Durability and long life

FRP Composite rebar have properties and features that increase the life of structures for many years without causing any damage. The durability and lifetime of this type of rebars is 15 times the steel mesh.