PRODUCT DESCRIPTION

What is Epoxy Grout?

Epoxy grout is a two-component mortar created by mixing epoxy resin with water. It is commonly used for grouting, planting rebar, filling cavities, and repairing concrete. It is also employed for adjusting the height of base and column plates. Epoxy grout is composed of fine-grained stone materials, which provide it with properties such as low shrinkage, easy application, high durability, strength, waterproofness, and cost-effectiveness. This versatile two-component epoxy grout is suitable for a wide range of large and small construction projects.

Due to its unique qualities, epoxy grout has gained popularity among tile contractors and builders. Unlike cement grout made from a cementitious powder mix, epoxy grout consists of epoxy resins and a filler powder. The resulting grout is highly durable and almost entirely stain-proof. Unlike regular grout, epoxy grout is waterproof and does not absorb water or stain easily. If you’re tired of dealing with stained grout, epoxy grout can be ideal.

Compared to cementitious grouts, epoxy grout offers greater bond strength and chemical resistance. It is made from two different resins mixed with a filler, making it highly waterproof and suitable for use with harsh cleaning products.

The distinction between two-component epoxy grout and cement grout lies in their composition and properties:

-

Damping properties:

Compared to cement grouts, epoxy grouts exhibit excellent damping properties for dynamic forces.

-

Bonding and adhesion:

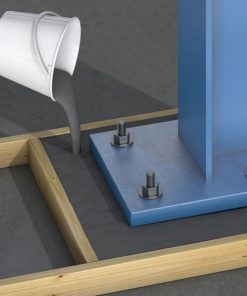

Epoxy grout provides better bonding and adhesion between the foundation concrete and base plates than cement grout.

-

Hardening time:

Epoxy grout cures faster than regular grout, reducing the required working time for the mixture.

-

Chemical resistance:

Epoxy grout demonstrates higher chemical resistance than concrete and cement-based grout.

-

Adhesion resistance:

Epoxy grouts have superior adhesion resistance, enabling them to withstand shear forces and lateral forces caused by wind, earthquakes, and other factors acting on the column plate.

-

Curing requirements:

Epoxy grouts do not require curing, except for the use of protective coatings in temperatures above 20 degrees or under canopies. In contrast, cement-based grouts are typically cured by water spraying for 5 hours or through the use of a curing agent.

-

Price:

The purchase price of epoxy grout can be 3 to 5 times higher than that of regular grout.

-

Thermal expansion:

The coefficient of thermal expansion for epoxy grouts is directly related to the product’s components and should align with the coefficient of heat for steel and concrete. The most pessimistic reports indicate a thermal expansion of 10 millionths of an inch per square inch of temperature rise per degree Fahrenheit. On the other hand, Portland cement-based grouts have a coefficient of thermal expansion of approximately 5.5.

Calculating Grout Volume:

Accurately estimating the required grout volume is crucial. Afzir Company has developed an online calculator tool to simplify this process that suggests the appropriate amount of grout based on your project’s operating conditions.

Choosing the Right Grout and Application Method:

Selecting the most suitable grout for your specific operation is essential. Additionally, ensuring the proper mixing of the grout’s two components guarantees the quality of your work. The grout and application method choice depends on various environmental conditions, considerations, and requirements. For instance, gravity grouting is recommended for small base plates, while the flow rate and fluidity of the grout should be prioritized for large surface areas.

The following tips will assist in selecting the appropriate grout and guiding its application:

-

Special situations and expandable grouts:

In specific weather conditions where moisture loss can occur due to air temperature and inadequate curing, expandable grouts are more suitable.

-

Grouting methods:

Grouting can be performed in two ways: gravity casting and pump application. Pump application ensures a consistent and evenly distributed grout flow, eliminating concerns about trapped air.

a. Pump application:

This method allows maximum resistance with minimum grout thickness. It is particularly advantageous when dealing with complex structures.

b. Gravity casting:

Gravity casting, on the other hand, utilizes the fluid and flowable states of the grout to achieve the required strength. It is suitable for situations where dough-like and fluid properties are needed while adhering to minimum grout thickness restrictions.

-

Vibration considerations:

Cement-based grouts are not recommended for environments with severe vibrations, as they can crack and break. For operations requiring high tensile flexural strength and adhesion, such as grouting under columns and baseplates, epoxy and polymer grouts are preferable.

-

International standards:

Epoxy grout based on ACI 351.1R-99 is recognized by international standards for its fluidity and effectiveness.

The efficiency of Epoxy Grout:

Determining the fluidity and efficiency of epoxy grout relies on scientific judgment, user experience, and engineering insight. It is essential to consider the efficiency time, which refers to the time from the start of mixing the two components to the drying and unusability of the epoxy grout. To ensure optimal results, the grout should be mixed before drying occurs.

Volume Change:

After pouring, clean epoxy resin typically experiences minimal shrinkage. Most of this shrinkage occurs while the epoxy resin is in a liquid state, so no further shrinkage occurs once it dries and withstands mechanical stresses.

Strength:

Epoxy grout exhibits long-term compressive strength generally 50 to 100% higher than hydraulic cement grout mixed to a smooth consistency. Moreover, the strength develops at a faster rate. Specially formulated epoxy resins can be loaded in less than 24 hours after application. Epoxy grouts offer high tensile strength and effectively reinforce clean and rough steel and concrete surfaces. Their increased strength and resilience enable them to absorb more energy during impact loading than hydraulic cement grout.

Epoxy Grout Layer Thickness:

The thickness of the epoxy grout layer used in structures depends on the distance between the base plate and other factors. Typically, it should not be less than 25 mm. The minimum grout thickness specified by ACI 351.1R-99 is 25 mm, which should increase by 13 mm for every 300 mm increase in grout flow.

Key Features

- High compressive, tensile and flexural strength

- Quick and easy implementation

- Using the highest quality materials to make grout

- Possibility of grouting in different thicknesses

- Minimum amount of creep under constant loading

- Resistant to constant dynamic loads

- Resistant to chemical environments

Applications

- Use it as a repairing grout to fill cavities and holes in concrete

- Grouting in confined spaces under columns, equipment and industrial machinery with fixed and moving loads.

- Installation of transmission cables and crane base

- Installation of screws and rebar planting and bolt planting in concrete

- Grouting in bridge seats

- Grouting on surfaces that require high resistance to mechanical loads and chemical and waterproof effects.

Packaging

- Buckets A = 20 kg and B = 10 kg

Colour

- Grey

technical specifications

|

density |

1800 kg/m3 |

| Working time (32℃) |

10-20 min |

| Shrinkage(7 days) |

– 0.0063 |

| Mixing ratio ( parts A:B ) |

2:1 |

| Tensile strength (7 days) |

14 MPa |

| flexural strength (7 days) |

30 MPa |

Familiarize Yourself with the Product:

- Understand the properties and application guidelines of ERG™200 code.

- Review documentation provided by the manufacturer.

Ensure Proper Surface Preparation:

- Clean the substrate surface thoroughly.

- Consider appropriate surface preparation techniques.

Follow Mixing Instructions:

- Adhere to recommended mixing ratios and instructions.

- Achieve a homogenous mixture.

Application Techniques:

- Choose suitable application tools.

- Apply the epoxy grout accurately and evenly.

Consider Working Time and Curing:

- Understand the pot life and plan accordingly.

- Monitor environmental factors that affect curing.

Safety Precautions:

- Wear appropriate PPE.

- Follow the safety guidelines provided.

Quality Control and Testing:

- Conduct regular quality control checks.

- Perform necessary testing for verification.

Documentation and Maintenance:

- Maintain detailed records of the grouting process.

- Provide maintenance recommendations to clients.

Grout Recipe:

- Minimum recommended run thickness: 20 mm.

- Maximum recommended run thickness: 100 mm.

Temperature Considerations:

- Do not apply grout at temperatures below 5°C (Suitable grout temperature should be above 5°C).

- Ensure the working environment meets the temperature requirements for proper grout application.

Dilution:

- Do not dilute the grout with any solvent, as it will compromise its compressive and tensile strength.

- Use the grout as per the manufacturer’s instructions without any modifications.

Substrate Concrete Age:

- The substrate concrete should be aged between 21 and 28 days, based on the curing and drying conditions.

- Ensure that the concrete has sufficiently cured and dried before applying the grout.

Please note that these guidelines are provided to ensure optimal performance and durability of the grout. Following these recommendations will help achieve the desired results.

Substrate Preparation:

- Ensure the concrete surface is clean and free from water, grease, and damaged areas.

- Approved chemicals can be used for cleaning the concrete surface.

Mixing:

- Open the bucket and remove the sheet. Pour the hardener (component B) into the resin bucket (component A).

- Stir the mixture using a spatula, hand mixer, or low-speed mixer. Avoid creating air bubbles.

- Excessive mixing can negatively affect the grout quality.

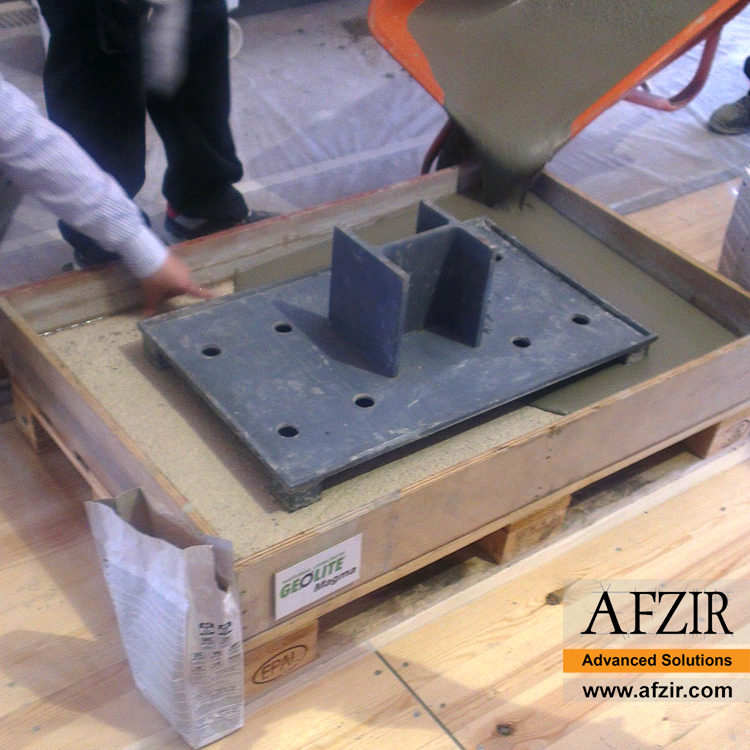

Grout Application:

- Pour the grout continuously from one side to remove air pockets.

- Maintain a continuous flow of grout throughout the application.

- Ensure sufficient grout is available before starting.

- Consider the product’s service life (Pot Life) during the grouting process.

Curing:

- Epoxy grout requires curing to retain moisture.

- Apply a curing coating or use a wet sack after pouring the grout, considering weather conditions.

- Allow for up to three days of curing, which will result in good compressive strength for loading.

Note: It is recommended to follow the manufacturer’s instructions for specific guidelines on substrate preparation, mixing ratios, application techniques, and curing methods for the epoxy grout being used.

Avoid Inhalation:

- Do not breathe in epoxy grout vapors.

- When working in environments with high grout vapor concentration, use air-purifying devices and masks to minimize inhalation of harmful gases.

- Keep epoxy materials away from fire, as burning epoxy can release dangerous vapors.

Prevent Skin and Eye Contact:

- Take precautions to avoid skin or eye contact with epoxy grout.

- In case of contact with the skin, wash thoroughly with soap and water.

- If epoxy grout comes into contact with the eyes, rinse immediately with plenty of water.

Review Product Precautions:

- Before using epoxy grout, carefully read and understand all precautions, specifications, and properties listed on the product.

- Follow the manufacturer’s guidelines for safe handling and usage.

technical documents

Photo Gallery

Technical documentation request

Frequently Asked Questions

What is two-component epoxy grout used for?

Two-component epoxy grout (ERG™ 200 code) is one of the types of epoxy base grout that is used in situations where the distance between the bottom of the column plate and under the base plate and the bed needs to be filled and the structural load is evenly distributed.

What are the components of epoxy grout?

Epoxy grout consists of two components, epoxy resin and hardener epoxy resin and is used as a very strong filler or adhesive to install and connect two structural sections and create high static and dynamic resistance.

What are the properties of two-component epoxy grout?

Epoxy grout is a two-component of the grout family that has high compressive, flexural and adhesion resistance. Also, two-component epoxy grout or grout is easy to apply and clean, with a bacteriostatic agent and Bio Block technology, ideal for injecting ceramic tiles.

Why is it recommended to use epoxy grout over cement grout for foundations?

Epoxy grout provides better bonding and adhesion than cement grout between the foundation concrete and the column plate and plates.

What is the effect of high tensile strength of epoxy grout on its performance on concrete and steel surfaces?

Higher strength and elasticity allow the grout to absorb more energy than cement grouts when loaded by impact.

What is the mixing ratio of epoxy grout components?

The components are combined in a ratio of 2 to 1. In fact, for every 2 components A, 1 component B must be mixed.

Where is epoxy two-component grout used?

Epoxy two-component grout for grouting floors and walls in shops, grouting industrial floors and walls, grouting in swimming pools, grouting tanks containing harmful chemicals, grouting ceramic tiles, acid-resistant tile adhesives, gluing marble doors and windowsills and It is also used to adjust the height of the base plate and the column plate.

What is the packaging of two-component epoxy grout?

Two-component epoxy grout is packaged in buckets A = 20 kg and B = 10 kg.

What is the difference between epoxy grout and cement grout?

Unlike cement grout, which is made from a mixture of cement powder, epoxy grout is made of two components of epoxy resin and hardener, which has a dynamic and static load bearing and higher resistance than cement-based grout. It also runs faster than cement grout.

Is the purchase price of epoxy grout more suitable or cement grout?

The purchase price of epoxy grout can be 3 to 5 times higher than cement grout, but according to the desired application and use, the type of grout can be selected.

Be the first to review “Two Component Epoxy Grout”