PRODUCT DESCRIPTION

The FRP paste epoxy gel reveals exceptional adhesion to construction materials like concrete and steel. This adhesive has high mechanical and chemical resistance and a suitable curing time. The epoxy adhesives and gels (ERS ™ 400 and ERS ™ 300) are highly valuable and appropriate for retrofitting projects and locations where impregnating and saturating FRP fibers in specific areas under beams and ceilings or installing pre-saturated fibers are not feasible. Furthermore, this product finds application in installing FRP rebars and FRP laminates.

Additionally, the versatility of the FRP paste epoxy gel extends to various other applications. It proves to be a reliable choice for bonding FRP rebars in the NSM method, providing enhanced structural reinforcement. Installing FRP laminates, which offer increased strength and durability, is another common use for this product.

The exceptional adhesion and durability of the epoxy gel make it suitable for demanding environments, including corrosive settings. This makes it an ideal option for projects requiring chemical exposure or high humidity resistance.

In summary, the FRP paste epoxy gel stands out for its strong adhesion, mechanical and chemical resistance, and suitability for retrofitting projects. Its versatile nature allows various applications, such as bonding FRP rebars and installing FRP laminates. Whether it’s reinforcing structures or withstanding challenging conditions, this epoxy gel is a reliable choice.

Key Features

- High mechanical and technical resistance

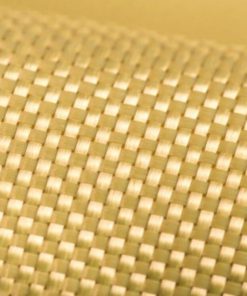

- Ability to saturate and install various types of FRP composite fibers

- Excellent adhesion to concrete, masonry, metals, wood, and other structural materials

- Suitable for implementing FRP fibers under beams, columns, slabs, walls, and concrete foundations

- Easy to use for FRP applications

- Suitable for vertical and overhead surfaces

- Long pot life for extended working time

- Resistant to corrosion and acidic environments

- Ample drying time for FRP retrofit projects

- Can be applied and installed with a spatula and roller

- Offers high abrasion and shock resistance

Applications

- Versatile epoxy adhesive suitable for various applications

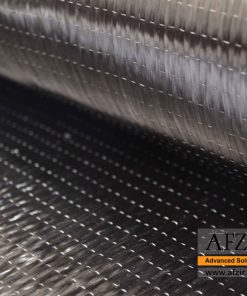

- Bonding composite strips and sheets to concrete, steel, wood, stone, and other building materials

- Structural connection of steel plates to concrete and other building materials

- Repairing damaged concrete surfaces and filling surface cavities

- Planting and anchoring rebars and bolts in concrete

- Installing woven and non-woven fibers

- Adhesive for filling empty spaces

- Leveling course and substructure for FRP surface retrofit

Packaging

- 15 and 30 Kg buckets

Colour

- Grey paste

technical specifications

| appearance |

Grey paste |

| Part A |

Light grey paste |

| Part B |

Grey paste |

| Shelf time |

18 month |

| Storage conditions |

Store dry at 4-40°C |

| Chemical base |

Epoxy Resin |

|

density |

1.25 Kg/L |

| Mixing ratio |

A:B = 100:50 |

|

Tensile strength (ASTM D638) |

25 MPa |

| pull off Adhesion testing |

2.5 MPa |

| Tensile modulus(ASTM D638) |

3500 MPa |

| fracture strain |

1% |

| curing temperature |

Between 25°C until 55°C |

| Initial setting time (at 25°C) |

5 hour |

| Final setting time(at 25°C) |

7 days |

| Pot life (at 25°C) |

90 min |

Additionally, when applying ERS ™ 400 epoxy paste adhesive and gel, it is essential to follow these instructions:

Surface Preparation:

Ensure that the application surface is clean, dry, and free from any contaminants such as dust, grease, or loose particles. Proper surface preparation will promote better adhesion.

Mixing:

Thoroughly mix the epoxy paste adhesive and gel according to the manufacturer’s instructions. Use a clean mixing container and mix the components until a homogenous consistency is achieved.

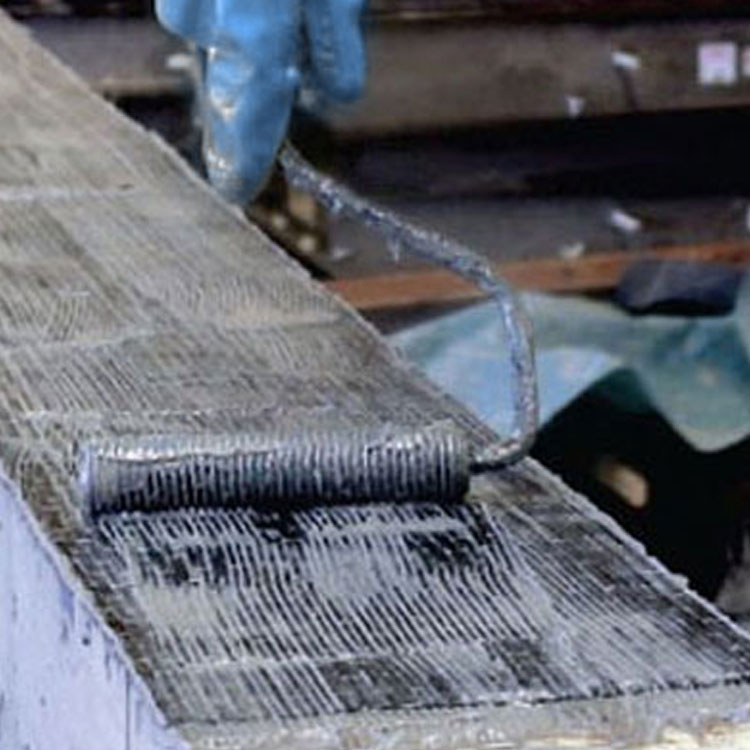

Application:

Apply the epoxy adhesive and gel onto the prepared surface using a suitable tool or applicator. Ensure consistent coverage, paying attention to specific application requirements or guidelines.

Curing:

Allow sufficient time for the epoxy adhesive and gel to cure according to the manufacturer’s recommendations. For optimal curing performance, Maintain appropriate conditions, such as temperature and humidity.

Safety Precautions:

Wear appropriate personal protective equipment (PPE) during the application process, including gloves, safety glasses, and respiratory protection, if necessary. Follow all safety guidelines and precautions provided by the manufacturer.

Tips:

- ERS ™ 400 epoxy paste adhesive and gel should not be applied below five °C.

- Avoid diluting ERS ™ 400 with solvent, as it can reduce its resistance.

- Ensure that the substrate concrete has aged between 21 and 28 days, considering the curing and drying conditions.

- When selecting a coating, consider the requirements for protection, aesthetics, and fire protection.

technical documents

Photo Gallery

Technical documentation request

Frequently Asked Questions

What is epoxy gel and FRP paste adhesive?

Epoxy gel and FRP paste adhesive is a combination of resin and hardener with relatively high viscosities. For this purpose, these types of adhesives have a paste or gel-like state. They also have a good drying or hardening time. This matrix provides excellent mechanical and chemical adhesion and stability after hardening.

For which surfaces is epoxy gel and FRP paste adhesive suitable?

Epoxy gel and FRP paste adhesive, due to its high concentration, is very suitable for vertical and sub-surface surfaces such as the surface under beams, columns, slabs, etc.

What is the difference between epoxy gel and FRP paste adhesive and ordinary epoxy adhesive?

Epoxy gel and FRP paste adhesive have a higher viscosity than ordinary epoxy adhesive. In addition, the pot life or working time of epoxy gel and FRP paste adhesive is longer than that of low viscosity epoxy adhesive.

What are the applications of epoxy gel and FRP paste adhesive?

Epoxy gel and FRP paste adhesive are widely used in strengthening and retrofitting various structures. Epoxy gel and FRP paste adhesive in applications such as producing FRP composite products and installing them on concrete and steel surfaces, etc., planting rebars and bolts in concrete, repairing damaged concrete surfaces and filling surface cavities, connection Structures of steel plates to concrete and other building materials are used as leveling and substructure of surfaces, etc.

What are the properties of epoxy gel and FRP paste adhesive?

Epoxy gel and FRP paste adhesive, with features or advantages such as high adhesion strength, high strength, high resistance to heat and moisture, good saturation, environmental friendliness, resistance to electricity, high resistance to chemical attacks And it has corrosion, curing or slow cooking, high user opportunity, etc.

What is the price and value of epoxy gel and FRP paste adhesive in the market?

The price of epoxy gel and FRP paste adhesive is determined per kilo unit. Due to market fluctuations, it is not possible to offer a single price per kilo of epoxy gel and FRP paste adhesive. For this purpose, to inquire about the daily price of the product, you can contact our sales experts in Afzir.

What are the methods of applying epoxy gel and FRP paste adhesive?

Epoxy gel and FRP paste adhesive, due to their high viscosity, are mainly applied by manual layering.

What are the rules and regulations for applying epoxy gel and FRP paste adhesive?

FRP paste epoxy adhesive and gel should not be applied at temperatures below 5 °C. It should not be diluted with solvent as it will reduce the resistance. Bedding concrete should be between 21 and 28 days old, depending on the curing and drying conditions. The surface must be free of any contamination before applying FRP paste epoxy adhesive and gel. Do not apply FRP paste adhesive and gel until the surface is dry, as curing may not be performed properly.

How to apply epoxy gel and FRP paste adhesive?

To apply epoxy gel and FRP paste adhesive, the surface must first be cleaned of any dirt and loose stains. Then mix epoxy gel and FRP paste adhesive according to the criteria in the product datasheet. Finally, apply the FRP paste epoxy glue and gel to the desired surface using a trowel or roller and allow to work well.

What are the physical properties of FRP paste epoxy adhesive and gel?

The color of the two components A and B (resin and hardener) that make up the adhesive and the epoxy gel of FRP paste are gray and white, respectively. Finally, by combining these two components, the epoxy gel and the FRP paste adhesive turn a grayish color. FRP paste epoxy adhesive and gel, at 21 ° C, provide about 90 minutes of working time.

Be the first to review “Epoxy Resin Saturant(ERS400)”