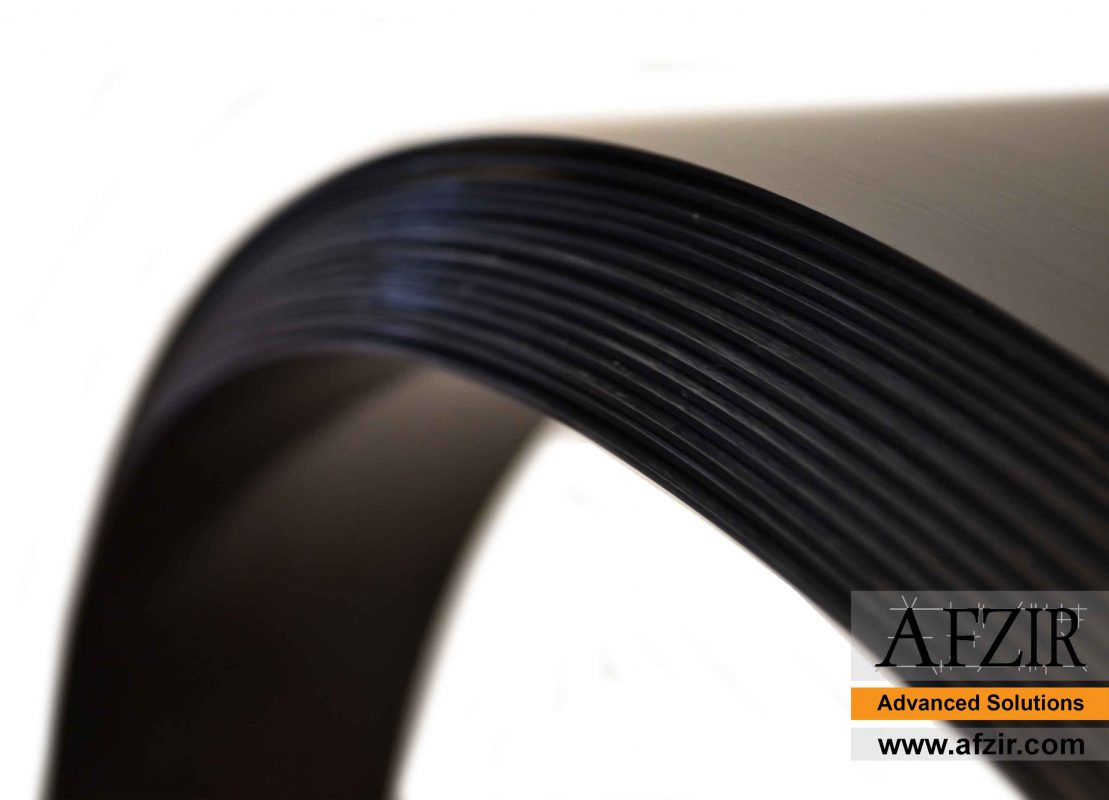

FRP Laminate

FRP Laminate (FRP Sheets) are multi-layer sheets that have a single or two-directional resistance and are bonded to concrete or steel surfaces with special FRP epoxy resin systems. FRP laminating is usually used to reinforce and increase the strength of reinforced concrete and pre-tensioned structures, which increases the stiffness and strength of the members, significantly, to control and prevent cracking in the plastic area of the members. The FRP sheet material, depending on its application, can be made of carbon, glass and aramid plates. The carbon type of which (CFRP laminate) is more widely used and offered in unlimited lengths and 10 and 5 centimeters widths.

Retrofitting with FRP Laminate

Along with advance of science and technology, modern materials have entered the construction and building industry, which also plays a significant role in retrofitting. These materials, which are currently used in building retrofitting, are FRP. In strengthening building with FRP, weak reinforced concrete elements such as beams, columns, shear walls and concrete slabs are strengthened using FRP fibers, which could be used to retrofit the whole building, or strengthening an individual component of a structure such as a beam or a column that has been weakened.

FRP retrofiting operations can be required for the following reasons:

- Mistakes and under design problems

- Construction problems and executive errors

- Change in standards and regulations

- Need to span the operation life of the building

- Change in the usage of the structure

- Increasing stories and dead load

FRP Laminate Application

Nowadays, unidirectional carbon-laminates are used in strengthening of beams and columns of buildings and bridge decks. The cost of repairing and replacing the bridge components is very high. Even when the conditions and facilities are provided when it comes to repairs, it creates many traffic problems. Regarding the above mentioned, modern retrofitting methods, such as the use of FRP materials to improve the structure of the bridge, cost less than replacing new parts and elements. It also decreases when the structure is retrofitted. Today, in the retrofitting industry, the FRP laminate sheets made of GFRP glass, AFRP aramid and CFRP carbon fiber, have replaced the steel plates due to their high strength and low weight. Super laminate is another FRP laminate product, that is usually used in pipe and tank retrofitting.

FRP Sheets

Nowadays, with the advancement of new materials, the building industry has employed them into the building retrofit. Among the new materials currently used in building retrofitting are FRP materials.

In retrofitting with FRP, weak reinforced concrete elements such as beams, columns, shear walls and concrete slabs are reinforced using FRP fibers. FRP fibers can also be used to retrofit the entire building, and can be used locally in one part of the structure or in one individual component, such as a beam or a column. It should be kept in mind that in retrofitting with FRP, design engineers have some design limitations that will prevent any weakened concrete elements from reinforcing with FRP or FRP laminates.

These restrictions include:

- Too low compressive strength of the constructed concrete.

- The rectangularity of the dimensions of concrete columns.

- The need to increase the stiffness in the weak element (this is usually discussed in the strengthening of beams and slabs).

- Strengthening of columns with high flexural moments and low compressive forces.

Advantages of FRP retrofitting

The most important advantages of using the FRP retrofitting method are the following:

- The fastness of the FRP retrofitting method compared to other building retrofit methods.

- Need to less demolition parts of the structure compared to other retrofitting methods.

- The need for less retrofitting operations on retrofitted elements to rebuild compared to other building rehabilitation methods.

- Retrofitting using FRP (in many respects) is less expensive in comparison with other methods.

Types of FRP retrofitting methods:

In general, existing concrete reinforced concrete structures or reinforcement and seismic repair are carried out to withstand gravity and earthquake loads. In this regard, a variety of retrofitting methods have been used to improve the defects due to the structure’s age or structural erosion, as well as to increase the structural ductility and improve the performance of the structure and its behavior against earthquake loads. One of the methods is strengthening with FRP.

- FRP fiber is a flattened polymer called Fiber Reinforced polymere, termed FRP.

- FRP fibers are a good replacement for traditional materials and current conventional methods for building retrofit.

- The FRP mechanism is that of fibers and resins used to make several composite layers.

- Resins used to bond several layers to concrete surfaces are used to protect composite materials.

- FRP fibers are lightweight and have high resistance to corrosion, rust and decay.

- Also, FRP fibers have a high tensile strength and a tensile strength of about 10 times that of steel.

FRP is used in different shapes and surfaces in multilayer sheets, called FRP laminate, or in a sheet that is like a fabric, which can be bent and twisted on the column and surface of the structural elements to be retrofitted. In most cases, FRP systems are produced in the form of thin profiles, and when applied to their appearance, they can be used in the finish and the final coating of the building. Although FRP materials are more expensive than conventional materials, such as steel and concrete, they are less costly in implementation costs, including the wages of the forces employed and the lack of special equipment compared to other building retrofitting systems.

- Non-corrosion and decay of FRP fibers in reinforced elements (compared to some methods, such as steel jacket).

- The basis of FRP retrofitting with modern retrofitting technologies.

- The elaboration of the FRP retrofitting procedure based on the latest laboratory and research methods.

- The existence of a test of the quality of FRP-reinforced element testing, such as the Pull-off test, to ensure the proper functioning of the retrofit system.

- No need for special equipment and tools compared to other retrofitting methods.

- Lack of high interference in building use compared with other traditional retrofitting methods.

- In cases where the use of heavy machinery or the operation of a building is not possible, the use of the FRP retrofitting method is the only building retrofit method.

- High Ratio to Weight and Hardness in FRP Reinforcement

- Having better connection with the concrete surface of the beam, column and shear wall in the FRP retrofitting method compared to the bond between the concrete and the steel jacket in the beam and column. This is due to the high bonding properties of FRP by epoxy adhesives on all surfaces. However, the reinforcement of the building with a steel jacket will only be achieved by using steel bolt to concrete.