PRODUCT DESCRIPTION

Accelerating High Range Water Reducing Admixture (AHW™) is an exceptional concrete additive that offers many benefits for construction projects. This cutting-edge admixture is specifically formulated to accelerate setting time, increase fluidity, and enhance the overall performance of concrete.

AHW™ utilizes state-of-the-art polycarboxylate technology, making it a third-generation solution at the forefront of concrete water reducers. Its mechanism of action is based on creating a repulsive force among cement particles, resulting in improved flow and workability. By effectively reducing the water-to-cement ratio, AHW™ enhances the compressive strength and durability of the concrete, leading to superior performance.

One of the key advantages of AHW™ is its ability to expedite the setting time of concrete, enabling faster attainment of initial and final strength. This feature benefits time-sensitive construction projects, ensuring efficient progress and shorter project timelines.

Moreover, AHW™ is highly compatible with various cement types and meets the stringent requirements of ASTM C494 standard. It can be seamlessly incorporated into different concrete applications, including high-strength concrete, precast elements, and ready-mix concrete.

By incorporating AHW™ into concrete mixes, construction professionals can achieve remarkable results. It improves the quality and strength of concrete and offers substantial cost savings by reducing water content and optimizing the use of cement.

With AHW™ as a reliable and innovative concrete additive, construction projects can benefit from enhanced performance, accelerated timelines, and cost-effective solutions, making it an indispensable choice for modern construction practices.

The growth rate of Accelerating High Range Water Reducing Admixture (AHW™) in the global market:

In recent years, there has been a growing demand for advanced concrete additives that can improve the performance and efficiency of construction projects. As a specialized and innovative solution, AHW™ holds significant potential for market growth due to its unique features and benefits.

Factors such as increasing urbanization, infrastructure development, and the need for sustainable construction practices are expected to drive the demand for high-performance concrete additives like AHW™. The construction industry’s focus on reducing project timelines, enhancing durability, and achieving cost savings further contributes to the potential growth of the market for AHW™.

Additionally, the adoption of advanced technologies in construction and increasing awareness of the benefits offered by specialized concrete additives are likely to fuel the demand for products like AHW™ in the global market.

It is important to note that the market’s growth rate for AHW™ can vary across different regions and markets. Factors such as regional construction trends, regulatory frameworks, and the availability of alternative products can influence growth.

To obtain the most accurate and up-to-date information on the rate of growth in the global market for AHW™, it is recommended to consult industry reports, market analysis, and reliable sources within the construction and concrete additive sectors. These sources can provide comprehensive insights into the current market dynamics and future growth prospects for AHW™.

Features

- It has super- plasticizer properties of concrete

- Has strong water reduction properties

- Increasing the speed of concrete setting

- Increase concrete slump

- Increasing the strength and durability of concrete

- Reduction of shrinkage and permeability in concrete

- Reduced separation even at high drops

- Increased compressive strength

- Increased bending strength

Applications

- This super-plasticizer can be used in all types of concrete, including ordinary concrete, prefabricated concrete and self-compacting concrete.

Packaging

- –

Colour

- Brown

technical specifications

|

chemical base |

polycarboxylate |

| Physical base |

liquid |

|

density |

1.04±0.02g/cm3 |

| Chloride |

no |

- Familiarize yourself with product specifications: Understand AHW™ characteristics and guidelines.

- Conduct compatibility tests: Test AHW™ with the intended concrete mix for compatibility.

- Determine the appropriate dosage: Work with mix designers to find the optimal AHW™ dosage.

- Follow proper mixing procedures: Follow recommended mixing techniques and instructions.

- Monitor and adjust as needed: Regularly assess concrete properties and make necessary adjustments.

- Consider project-specific requirements: Tailor AHW™ usage to meet unique project specifications.

- Stay updated on industry best practices: Stay informed about the latest advancements and guidelines.

- Collaborate with suppliers and manufacturers: Build relationships for technical support and guidance.

- Source from reputable suppliers: Choose reliable suppliers with quality AHW™ products.

- Train your workforce: Provide training on AHW™ handling, mixing, and safety precautions.

- Conduct on-site trials: Test AHW™ performance and compatibility before large-scale use.

- Monitor concrete placement: Monitor workability, setting time, and strength development.

- Communicate with stakeholders: Maintain open communication with engineers and suppliers.

- Document and track results: Keep detailed records for future reference and evaluation.

- Stay updated with industry advancements: Stay informed to leverage new technologies and techniques.

- Determine the required dosage: Calculate the appropriate dosage of AHW™ based on the cement used in the concrete mix. The recommended dosage range is 500 to 1500 ml of AHW™ per 100 kg of cement.

- Measure the AHW™ dosage: Using a measuring container or dispenser, accurately measure the required amount of AHW™ based on the calculated dosage.

- Incorporate AHW™ into the mix: Add the measured AHW™ dosage to the concrete mixer during the concrete mixing process. Ensure that AHW™ is uniformly distributed throughout the mix to achieve consistent performance.

- Adjust water content: As AHW™ is a water-reducing admixture, adjusting the water content in the concrete mix is essential. Follow the recommended water-cement ratio the concrete mix design provides to maintain the desired workability and strength.

- Mix thoroughly: Operate the concrete mixer according to standard procedures, ensuring that AHW™ is thoroughly mixed with the other ingredients. Follow the recommended mixing time and techniques to achieve optimal dispersion of AHW™ within the mix.

- Monitor the concrete properties: During and after mixing, monitor the concrete properties such as workability, setting time, and strength development. Make adjustments if necessary to achieve the desired results, considering project-specific requirements and local conditions.

- Adhere to curing practices: Follow appropriate practices to allow the concrete to develop its full strength and durability. Consider any specific curing requirements based on the project specifications and AHW™ usage.

- Procurement and Storage: Source AHW™ from reputable suppliers and store it properly.

- Testing and Compatibility: Conduct initial and regular tests to ensure AHW™ compatibility and performance.

- Dosage Control: Follow recommended dosage guidelines and accurately measure AHW™ dosage.

- Mixing and Dispersion: Ensure thorough mixing and uniform dispersion of AHW™ in the concrete mix.

- Workability and Setting Time: Monitor and adjust water content to maintain desired workability and setting time.

- Strength and Durability: Test concrete strength and monitor long-term durability factors.

- Documentation and Record-Keeping: Maintain detailed records of AHW™ usage, mix designs, and testing results.

- Collaboration and Communication: Foster stakeholder collaboration and communicate with AHW™ manufacturer for support and updates.

technical documents

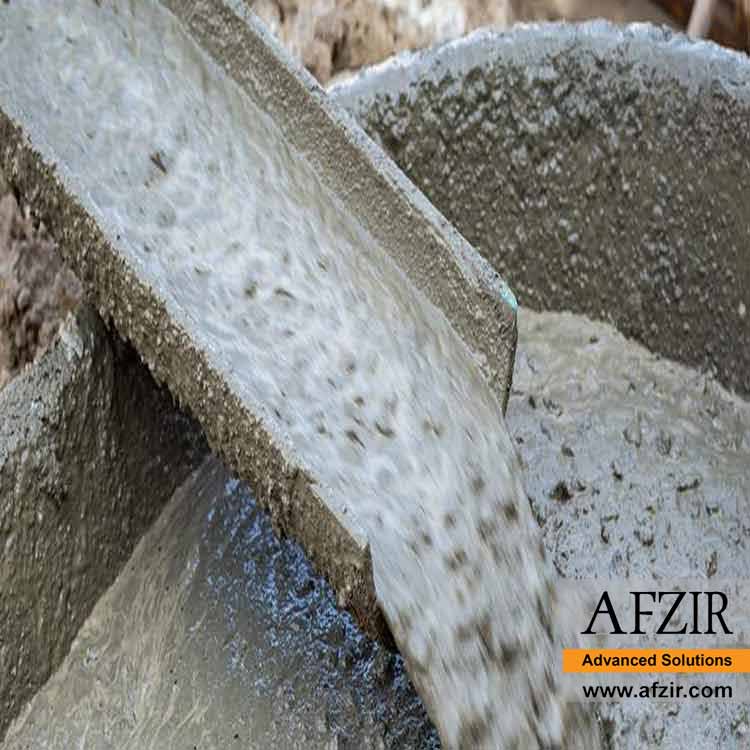

Photo Gallery

Technical documentation request

Be the first to review “Set Accelerating High Range Water Reducing Admixture”