FRP SuperLaminate

The high tensile strength, light weight, durability and versatility of FRPs have made these products the material of choice for many repair and rehabilitation projects. To date, numerous bridges, buildings, pipelines, etc. have been retrofitted with these products worldwide. With the publication of design guidelines (ACI 440‐08) it is fair to say that FRP is no longer an experimental product but rather a relatively well‐accepted construction material.

The forms of FRP products that have been used in retrofit applications to date can be categorized into fabrics and pre‐cured laminates. Fabrics offer the widest versatility in the field and are installed with what is commonly referred to as the wet layup method. This technique requires properly trained technicians to prepare the resin in the field, saturate the fabric and apply it to the structural member.

Care must be taken to ensure the fibers are aligned in proper directions and to remove all air bubbles before the fabric is cured.

Pre‐cured laminates allow easier field installation because the saturation of fibers mentioned above is carried out in a plant. They are available in the shape of reinforcing rods or tendons as well as narrow unidirectional laminate strips that are typically produced in the range of 3‐4 inches (75 – 100 mm) wide and 0.05 inches (1.3 mm) thick. In the field, these laminate strips are bonded to the exterior surface of the structural element using epoxy putty. A variation of this approach known as Near Surface Mounted (NSM) embeds the laminate strips or rods into narrow grooves that are cut in he structural member.

While the laminate strips offer ease of installation and higher strength than the wet layup system, their use has been relatively limited for the following three reasons: a) the unidirectional reinforcement in these laminates makes them primarily suitable only for flexural reinforcement of beams and slabs, with some applications for shear strengthening of beams, b) the stiffness of the laminates does not allow them to be coiled into a circle smaller than approximately 30 inches (750 mm) in diameter, and c) their relatively narrow width is a hindrance in many applications.

The current equipment and technique used to manufacture these laminate strips does not lend itself to making products that are appreciably different. Even with modification of current equipment, one can only produce unidirectional laminate strips that are no wider than approximately 10 inches (255 mm). The overcoming of the above shortcomings in laminate strips is not a trivial matter. In fact, some contractors tried to use 10 inch (250 mm) wide laminate strips in repair of pipelines and abandoned the idea after unsuccessful attempts (Carr 2009).

Super Laminates

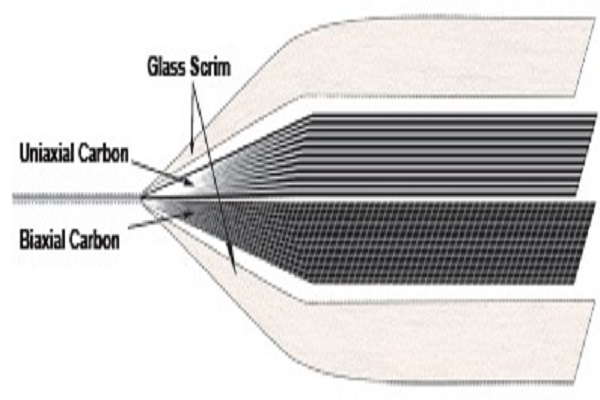

Super laminates are a frog leap development in FRP products since the introduction of FRP in construction industry some twenty years ago. They overcome the shortcomings of the abovementioned laminate strips. As discussed below, these products make possible many applications that have challenged the construction industry for decades. In some case, the solutions have not been possible without the development of super laminates. Super laminates are constructed with specially‐designed equipment. Sheets of carbon or glass fabric up to 60 inches (1.5 m) wide (Fig. 1) are saturated with resin and passed through a press that applies uniform heat and pressure to produce the laminates. Super laminates offer three major advantages over conventional laminate strips:

1) By combining unidirectional and/or biaxial fabrics, the laminates offer strength in both longitudinal and transverse directions; this is a tremendous advantage that opens the door to many new

applications as discussed later.

2) They are much thinner than conventional laminates; with a typical thickness of 0.025 inches (0.66 mm), they can fit into a cylinder with a diameter as small as 8 inches (200 mm).

3) The number and design of the layers of fabrics can be adjusted to produce an endless array of products that can significantly save construction time and money.

Biaxial glass carbon frp laminate repair

The figuure abovve shows typical super laminates and their flexibility that allows them to be bent by hand. They are produced under ISO‐9000 certification that ensures highest standards of quality control. This eliminates much of the reliance that has been placed in the past on the construction crew to produce the FRP in the field using the wet layup system. For example, when the rolls of super laminates are delivered to a construction site, samples can be tested before the material is installed. In contrast, in the wet layup application, fieldprepared samples are made daily and tested at a later date, at which time repair of defective installations cannot be easily corrected.

The flexibility of the super laminate is demonstrated by coiling it in smaller diameters and by easily folding a corner of the large carbon panel. Super laminates can be produced with highest quality control under ISO 9000 certification; this will provide a leapfrog advance in wider acceptance of FRP products in construction projects.