PRODUCT DESCRIPTION

Acid-resistant mortar, based on epoxy resin, is a highly durable material specifically designed to withstand acidic and corrosive environments. This type of mortar offers exceptional resistance to sulfuric acid, withstanding concentrations of up to 95%. It is commonly utilized to protect surfaces that are exposed to corrosive substances. Suppose you want to purchase a chemical-resistant mortar based on the epoxy resin (AREM™ code). In that case, we recommend contacting our experts, who can provide detailed information regarding the purchasing process and pricing. They can assist you with any inquiries you may have regarding this product.

Whether you require acid-resistant mortar for industrial facilities, laboratories, storage areas, or infrastructure repair, our epoxy-based solution provides the durability and protection you need. With its outstanding resistance to sulfuric acid, up to concentrations of 95%, our acid-resistant mortar is the go-to choice for safeguarding surfaces against corrosive substances.

This product is carefully formulated using high-quality epoxy resin, ensuring its exceptional durability and long-term performance. The mortar creates a seamless and impenetrable barrier, effectively preventing acid penetration and corrosion damage to underlying surfaces.

In addition to its superior acid resistance, our epoxy-based mortar exhibits excellent adhesion properties, allowing it to bond securely to various substrates such as concrete, metal, and masonry. This ensures reliable protection even in harsh environments with high exposure to chemicals.

Features

- Resistant to strong oxidizing agents, non-oxidizing acids, alkalis, salt, detergents, oils, greases, etc.

- High chemical and thermal resistance

- No wear and tear

- High adhesion, tensile and compressive strength.

- It has high mechanical resistance and improves physical properties.

Applications

- Making floors, tiling, etc.

- Protective coating of surfaces that are in the vicinity of destructive chemicals.

- bedding mortar

- Adhesive mortar for tanks, floor, drainage, foundation

- Protective cover of tanks and wells

- Protective covering of sulfuric acid and sulfur production plants and their storage tanks

Packaging

- Two-components pockets

Colour

- white

technical specifications

|

Mixing ratio |

A: B=2:1 |

|

density |

1. 8 Kg/cm3 |

| Pot life |

20 min |

|

compressive strength |

500 Kg/cm2 |

|

Flexural strength |

150 Kg/cm2 |

| cohesive bond |

12 Kg/cm2 |

- Thoroughly Evaluate Project Requirements: Carefully assess project factors such as chemical exposure, temperature range, mechanical stress, and surface conditions to select the most suitable acid-resistant epoxy-based mortar.

- Follow Manufacturer’s Guidelines: Refer to the manufacturer’s technical data sheets and guidelines for proper mixing ratios, surface preparation, application techniques, curing times, and precautions.

- Conduct Proper Surface Preparation: Ensure thorough cleaning and, if necessary, mechanically prepare the surface for optimal adhesion between the mortar and substrate.

- Use Correct Mixing Techniques: Accurately measure and mix the epoxy resin and hardener components to achieve uniform mortar consistency.

- Apply Mortar with Proper Techniques: Utilize suitable tools and techniques for even and consistent application, achieving the desired thickness and coverage.

- Monitor Curing Conditions: Maintain recommended temperature, humidity, and ventilation during the curing process while protecting the mortar from excessive moisture, sunlight, or temperature variations.

- Conduct Quality Control Testing: Regularly perform adhesion tests, acid resistance tests, and visual inspections to ensure the mortar’s integrity and performance.

- Prioritize Safety: Follow safety protocols and wear appropriate personal protective equipment (PPE) when handling and applying acid-resistant epoxy-based mortars.

- Seek Expert Advice: Consult experienced professionals or the manufacturer’s technical support team for guidance and assistance throughout the project.

- Understand the Project Requirements: Gain a thorough understanding of project specifications, including acid types, surface conditions, temperature range, and mechanical stress.

- Collaborate with Engineers and Designers: Work closely with experts to align the chosen acid-resistant epoxy-based mortar with project requirements.

- Follow Manufacturer’s Guidelines: Adhere to technical data sheets, application guidelines, and safety recommendations provided by the manufacturer.

- Thoroughly Prepare the Surface: Properly clean and prepare the substrate, removing dirt, dust, grease, and loose particles.

- Utilize Skilled and Trained Workforce: Assign trained personnel knowledgeable about the product, application techniques, and safety protocols.

- Follow Correct Mixing Procedures: Accurately measure and mix the epoxy resin and hardener components according to recommended ratios.

- Employ Suitable Application Techniques: Use appropriate tools and techniques for applying the mortar, ensuring consistent thickness and coverage.

- Monitor Curing Conditions: Maintain recommended temperature, humidity, and ventilation during the curing process.

- Conduct Quality Control Inspections: Regularly inspect applied mortar for coverage, thickness, adhesion, and quality.

- Prioritize Safety: Ensure workers have proper personal protective equipment (PPE) and follow safety protocols.

- Maintain Communication with Suppliers and Manufacturers: Establish open lines of communication for support and guidance throughout the project.

Surface Preparation:

- Ensure all surfaces are clean, dry, and free from dust, dirt, grease, oil, and other contaminants.

Mixing and Application:

- Thoroughly stir the epoxy resin before use.

- Pour the liquid resin into a suitable container.

- Follow the specified mixing plan and add the hardener and filler accordingly.

- Mix the components thoroughly using a spatula or trowel until a uniform mixture is achieved.

- Use all the mortar from the mixing bowl before preparing another batch.

Setting and Curing:

- The epoxy resin will self-harden when the resin, hardener, and filler are mixed.

- Initial setting occurs within 5 hours at a temperature of 30°C.

- Final setting occurs within 24-48 hours at a

- Allow the mortar to cure for 7 days at a temperature of 30°C.

Note: Following the manufacturer’s instructions for the acid-resistant epoxy-based mortar is essential, as curing times and temperatures may vary depending on the product.

- Adhesion Test: Conduct tests to assess the bond strength between the mortar and substrate.

- Acid Resistance Test: Evaluate the mortar’s ability to withstand exposure to specific acids or corrosive substances.

- Visual Inspection: Regularly inspect the mortar visually for defects, uniformity, and desired coverage.

- Documentation and Record-Keeping: Maintain detailed records of quality control activities and test results.

- Compliance with Standards: Ensure the mortar meets industry standards and project requirements.

- Collaboration and Expert Consultation: Seek expert guidance and collaborate with stakeholders for quality control.

technical documents

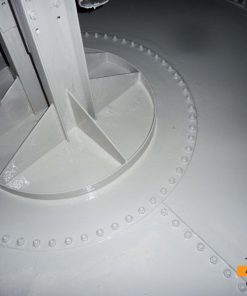

Photo Gallery

Technical documentation request

Be the first to review “Acid Resistant Epoxy Based Mortars”