PRODUCT DESCRIPTION

Novalac epoxy vinyl ester resin (NVER™ 990 Code) is a high-quality product that undergoes meticulous production to ensure exceptional performance and reliability. This resin is formulated using Novalac epoxy as a base, resulting in a robust and versatile solution for surface protection.

A carefully balanced blend of ingredients is combined to achieve optimal chemical resistance and thermal stability during production. This resin is designed to withstand the harshest chemical environments, including exposure to high-concentration acids, alkalis, and solvents. Its advanced formulation ensures excellent protection for concrete surfaces, guarding against the corrosive effects of various chemical factors.

The production process involves precise control over temperature, reaction times, and curing conditions to achieve a resin with superior properties.

NVER™ 990 Code exhibits remarkable stability even at elevated temperatures, making it highly reliable for heat exposure applications.

Furthermore, this resin plays a crucial role in enhancing the adhesion and resistance of FRP fibers at high temperatures. By incorporating Novalac epoxy vinyl ester resin into fiber-reinforced plastics, the resulting composite materials demonstrate enhanced durability and performance in demanding environments.

Every batch of Novalac epoxy vinyl ester resin (NVER™ 990 Code) undergoes stringent quality control measures to ensure consistency and meet the highest industry standards. With its excellent chemical resistance, thermal stability, and reinforcement capabilities, this resin is a trusted choice for surface protection, making it an ideal solution for various industrial applications.

The purchase price of Novalac epoxy vinyl ester resin

Several key factors influence NVER™990: These factors include the quantity purchased, with larger orders potentially resulting in lower unit prices. The choice of supplier or distributor also plays a role, as pricing structures vary among providers. Market demand for the resin, fluctuations in raw material costs, and the quality and specifications of the product can all impact the purchase price. Market conditions, such as economic trends and global supply chain dynamics, can also contribute to price fluctuations. To obtain accurate pricing information, it is advisable to consider these factors and consult suppliers or industry-specific pricing databases.

Features

- Excellent chemical resistance against acids and bases

- High mechanical strength and wear resistance

- Excellent adhesion to surfaces

- Increasing durability and longevity of surfaces

- Protection of surfaces at high temperatures

- It is insoluble and does not dissolve in water, so it does not harm the environment.

- Quick and easy implementation

- Increasing the strength and adhesion of FRP fibers at high temperatures

Applications

- Concrete and metal tanks

- Storage tanks for chemicals

- Protection of surfaces against splashing harmful chemicals on surfaces

- Refineries and petrochemicals

- Battery rooms

- Chemical storage warehouse

- Increasing the adhesion of FR fibers

Packaging

- In 23KG buckets

Colour

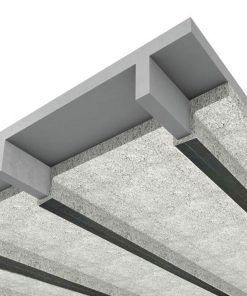

- grey

technical specifications

|

color |

grey |

|

Mixing ratio |

A:B=2:1 |

| Pot life |

45 min |

|

Setting time |

4.5 hours |

|

density |

1.25Kg/L |

| Shelf time |

6 months |

- Understand the Properties: Familiarize yourself with the specific properties and characteristics of Novalac epoxy vinyl ester resin.

- Follow Manufacturer Guidelines: Adhere to the guidelines provided by the manufacturer for handling, storage, and application of the resin.

- Consider Compatibility: Evaluate the compatibility of the resin with other materials and substrates used in the project.

- Test and Validate: Conduct thorough testing and validation of the resin’s performance in real-world conditions.

- Seek Technical Support: Reach out to the manufacturer or supplier for technical support when facing challenges or needing guidance.

- Stay Updated: Stay informed about advancements, research, and Novalac epoxy vinyl ester resin updates.

- Training and Certification: Ensure your team is trained and certified for safely handling and applying Novalac epoxy vinyl ester resin.

- Surface Preparation: Properly clean and prepare the substrate according to manufacturer guidelines for optimal adhesion.

- Application Techniques: Follow recommended application techniques, including temperature ranges, mixing ratios, and tools.

- Safety Measures: Prioritize safety with proper personal protective equipment, ventilation, and adherence to safety protocols.

- Quality Control: Implement a robust process to monitor applications and address defects or inconsistencies.

- Collaboration and Communication: Maintain open communication with stakeholders to ensure a smooth workflow and address concerns effectively.

- Post-Application Care: Guide clients on maintenance and cleaning procedures to extend the lifespan of the resin coating.

Surface Preparation:

- Ensure the surface is clean and free from contaminants like dust, oil, and chemicals.

- Use a vacuum or high-pressure device to remove dust and wash the surface if needed.

- Repair any weak areas and ensure the surface is dry.

Note: Cut corners and sharp points in a curve with a minimum radius of 3 cm.

Epoxy Novalac Vinyl Ester Resin Preparation:

Stir the two components separately before pouring component B into component A. Mix thoroughly for 3 to 5 minutes. Apply the resin using a spray or roller application method.

- Inspection of Raw Materials: Thoroughly inspect and verify the quality of incoming raw materials.

- Mixing and Proportioning: Follow proper mixing ratios and procedures to achieve a homogeneous blend.

- Application Testing: Conduct initial tests to evaluate compatibility, adhesion, appearance, and curing characteristics.

- Adhesion Testing: Use appropriate methods to assess the bond strength between the resin and substrate.

- Curing and Hardness Testing: Monitor the curing process and perform hardness tests to ensure desired hardness level.

- Visual Inspection: Regularly inspect for defects like bubbles, cracks, or uneven coating thickness.

- Chemical Resistance Testing: Test resin’s compatibility and performance against representative chemicals.

- Documentation and Record-Keeping: Maintain comprehensive records of quality control activities.

- Compliance with Standards: Ensure adherence to industry standards and guidelines.

technical documents

Photo Gallery

Technical documentation request

Be the first to review “Novolac Epoxy Vinyl Ester Resin”