PRODUCT DESCRIPTION

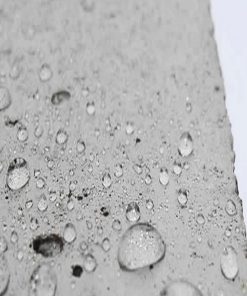

Concrete surfaces and depths can often contain pores, defects, and imperfections caused by inadequate vibration, poor compressibility, incomplete hydration, or non-compliance with concreting standards. These openings in the concrete can serve as pathways for the ingress of water or chemicals, leading to significant damage to the concrete structure. The ideal solution is to achieve impermeability in concrete to mitigate such issues arising from moisture penetration, weathering, freeze-thaw cycles, or other environmental conditions. NAW™CB, a Nano-sealing additive produced using advanced nanoparticle technology, offers precisely that solution. This nano-waterproofing material is incorporated into the concrete mixture as a nano-waterproofing additive during the mixing process. Upon introduction, the nanoparticles of this moisture-insulating additive crystallize and grow in three directions, effectively sealing off pores and defects on the concrete surface and within its depths. As a result, the concrete surface becomes hydrophobic, dustproof, and highly resistant to the penetration of water and other harmful substances. Concrete mixed with this nano insulation demonstrates significantly increased service life compared to ordinary concrete. The nano insulation product mixed with concrete (NAW™CB code) finds valuable applications in the construction of prefabricated concrete components used in building facades, tables, etc., as well as in scenarios where concrete is exposed to harsh environmental conditions, particularly chlorides, and sulfates.

Application of Nano Waterproofing

Nano Waterproofing offers various applications, providing practical solutions for different construction and infrastructure projects. By incorporating this advanced technology, numerous surfaces and structures can benefit from enhanced water resistance and protection against environmental factors. This innovative solution is commonly used for waterproofing pools, water tanks, and wet areas such as kitchens and sewage treatment plants. It also proves valuable in sealing retaining walls, parking lots, tunnels, basements, dams, and water and sewage transmission channels. Moreover, Nano Waterproofing strengthens concrete components, including shear walls, retaining walls, beams, columns, slabs, piles, and micro piles, effectively increasing their load-bearing capacity and durability. Additionally, it demonstrates remarkable performance in marine environments, making it an ideal choice for concreting projects exposed to corrosive elements. With its versatility and effectiveness, Nano Waterproofing ensures long-lasting, water-resistant structures across various applications.

Pricing of Nano Waterproofing (NAW™CB)

The price of Nano waterproofing for concrete mixing (NAW™CB) is subject to various factors, including market fluctuations, the brand and country of the manufacturer, and the specific ingredients used. As a result, it is not possible to provide a fixed price. The cost may vary. We recommend contacting our experts at Afzir Retrofitting Company for advice or detailed inquiries regarding the pricing of nano-sealing materials or other products and materials.

Features

- Turning concrete itself into a sealing agent

- High resistance of concrete waterproofing

- Making the concrete structure more uniform

- Increasing the contact surface of cement and aggregate

- Increasing the efficiency of concrete

- Increasing the durability of concrete

- Preventing the penetration of chlorine and sulfate ions

Applications

- Sealing

- Increasing the strength of concrete

- Increasing the efficiency of concrete

- Increasing the density of concrete

Packaging

- –

Colour

- colorless

technical specifications

|

Physical base |

liquid |

| Chemical base |

Nano silica SiO2 |

|

Amount of consumption |

Determined by in-place testing. |

| functional mechanism |

Turning concrete itself into a waterproofing agent |

|

Maintenance |

In a closed place and away from direct sunlight |

| Melting point |

-77.9 ℃ |

|

Boiling point |

126.5 ℃ |

| solvent |

Cold water |

| color | colorless |

- Familiarize yourself with the technology: Deeply understand nano waterproofing principles and advancements.

- Conduct comprehensive site assessments: Evaluate site conditions and potential sources of moisture ingress.

- Collaborate with manufacturers and suppliers: Work closely with reputable nano waterproofing product providers for guidance.

- Follow proper application guidelines: Adhere to recommended application procedures for optimal results.

- Consider long-term performance: Assess the durability and maintenance requirements of the nano waterproofing solution.

- Collaborate with other disciplines: Coordinate with structural engineers, architects, and contractors for seamless integration.

- Perform regular quality control checks: Implement inspections and testing to ensure effective waterproofing.

- Stay informed about regulations and standards: Stay updated on relevant codes and guidelines.

- Document and share experiences: Maintain records and share knowledge within the engineering community.

- Continuous professional development: Engage in ongoing learning to stay updated on advancements in nano waterproofing.

- Gain expertise in nano waterproofing: Acquire in-depth knowledge of the technology and its applications.

- Collaborate with engineers and designers: Maintain clear communication and coordination with project stakeholders.

- Follow manufacturer guidelines: Adhere to specific instructions provided by the product manufacturer.

- Ensure proper surface preparation: Thoroughly clean and prepare concrete surfaces before application.

- Employ trained and experienced personnel: Assign skilled workers familiar with nano waterproofing techniques.

- Use suitable equipment and tools: Select appropriate tools and equipment for the application process.

- Implement proper safety measures: Prioritize worker safety and adhere to safety protocols.

- Monitor application conditions: Consider environmental factors during application for optimal results.

- Perform quality control checks: Inspect and test the applied nano waterproofing for effectiveness.

- Document and communicate: Maintain detailed records and communicate with stakeholders throughout the process.

- Surface Preparation: Ensure a clean and structurally sound concrete surface.

- Mixing: Measure and add the recommended dosage of NAW™CB to the concrete mixture, ensuring thorough mixing.

- Application: Evenly apply the NAW™CB-infused concrete mixture to the intended surfaces.

- Curing: Follow standard concrete curing practices to allow the concrete to gain strength.

- Quality Control: Regularly inspect and test the performance of the nano additive waterproofing.

- Safety Precautions: Adhere to safety guidelines and wear appropriate protective equipment.

- Maintenance and Longevity: Conduct regular inspections and perform necessary maintenance to ensure the durability of the waterproofing system.

- Understand the product: Familiarize yourself with NAW™CB nano waterproofing specifications and guidelines.

- Establish quality control procedures: Develop a comprehensive plan outlining steps, inspections, and tests.

- Verify product authenticity: Ensure the NAW™CB nano waterproofing is genuine and reliable.

- Surface preparation: Follow instructions for cleaning and preparing the substrate before application.

- Proper mixing: Accurately measure and mix NAW™CB according to recommended ratios.

- Application consistency: Apply NAW™CB uniformly using the recommended method.

- Adhesion and compatibility: Verify adhesion and compatibility with other materials through tests or consultation.

- Curing process: Follow recommended curing procedures for optimal performance.

- Inspections and testing: Perform regular inspections and tests to assess quality and effectiveness.

- Documentation: Maintain detailed records of quality control activities for reference.

- Continuous monitoring: Monitor the performance of NAW™CB over time.

- Collaboration with stakeholders: Communicate effectively with project stakeholders to address concerns and modifications.

technical documents

Photo Gallery

Technical documentation request

Be the first to review “Waterproof Nano Additive”