PRODUCT DESCRIPTION

Introducing Polyamine Epoxy Coating (PEP™ code), a high-performance solution that provides superior surface protection and durability. This cutting-edge epoxy coating combines a solvent-free epoxy resin with a polyamine hardener, resulting in a strong and resilient final product.

PEP™ code is formulated using advanced technology and resistant pigments, ensuring exceptional chemical resistance and defense against destructive agents. Whether faced with harsh chemicals or external elements, this coating stands strong, maintaining its integrity over time.

One of the key advantages of PEP™ code is its seamless application process, which eliminates the formation of seams and cracks. This feature not only enhances the aesthetic appeal but also strengthening the coating against thermal and mechanical forces. As a result, the durability and quality of the epoxy remain uncompromised throughout its lifespan.

Versatility is another standout characteristic of the PEP™ code. It can be applied to various surfaces, including concrete, metal, and stone, making it suitable for a wide range of applications. With its exceptional adhesion, heat resistance, and mechanical properties, this epoxy coating offers reliable protection and longevity in diverse environments.

Choose Polyamine Epoxy Coating (PEP™ code) for your next project and experience unparalleled durability, chemical resistance, and aesthetic appeal. With the PEP™ code, you can trust that your surfaces will receive the highest level of protection and maintain their quality for years to come.

Compatibility with Other Protective Coatings

Polyamine Epoxy Coating (PEP™ code) is compatible with various protective coatings, offering flexibility and customization options for re-coating projects. Compatible options include alkyd, phenolic alkyd, alkyd silicon, urethane alkyd, two-component epoxy, polyurethane, and acrylic. Additionally, immediate application after the epoxy floor primer allows using two-component acrylic, acrylic latex, chlorinated rubber, and two-component polyurethane coatings. The compatibility of the PEP™ code ensures seamless integration and enhanced durability for a wide range of flooring applications.

Key Features

- Resistance to chemicals and destructive substances

- Good resistance to mechanical forces

- Good adhesion to concrete surfaces

- Seamless run and crack

- Solvent resistant

- Ability to run on a variety of concrete, metal and stone surfaces

- Ideal chemical properties

- High abrasion and compressive strength

Applications

- Epoxy flooring in the military industry

- Petrochemical epoxy flooring

- Epoxy flooring for chemical and electronics factories

- Epoxy flooring packaging industry

- Epoxy flooring for industrial and pharmaceutical factories

- Textile epoxy flooring

- Industrial epoxy flooring for refrigerators

- Epoxy flooring for power plants and slaughterhouses

- Epoxy flooring for workshops and gyms

- Epoxy flooring of hospitals

Packaging

- In weights of 160 to 300 grams per square meter and 50 and 100 mm in width

Colour

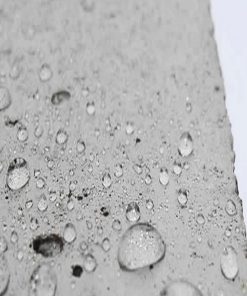

- Gray (Available in other colors)

technical specifications

| color |

Gray (Available in other colors) |

| optimal thickness |

1000 μm |

| Volume solid |

100% |

|

density |

1.5 g/cm3 |

|

Initial setting time |

6-8 hours |

| Final setting time |

7 days |

| Gel time |

5 minutes |

| Pot life |

1 year |

- Familiarize Yourself with Product Specifications: Understand the technical details and application guidelines for PEP™ code to ensure proper usage and performance.

- Surface Preparation is Key: Thoroughly clean and prepare the surface to ensure optimal adhesion of PEP™ code.

- Follow Recommended Mixing Ratios: Accurately measure and mix the epoxy resin and hardener components for desired results.

- Use Appropriate Application Techniques: Choose the suitable method (brush, roller, spray) to apply PEP™ code evenly for a consistent finish.

- Allow Sufficient Curing Time: Give PEP™ code enough time to fully cure before subjecting it to foot traffic or other loads.

- Ensure Proper Ventilation: Maintain good airflow during application to aid in curing and avoid issues like trapped air bubbles.

- Maintain Safety Precautions: Wear appropriate personal protective equipment (PPE) and follow safety guidelines when working with the PEP™ code.

- Regular Maintenance and Inspection: Conduct periodic inspections and perform maintenance tasks to identify and address any wear or damage, ensuring the longevity and performance of the PEP™ code.

- Understand Product Specifications: Familiarize yourself with the PEP™ code’s technical details and application guidelines to ensure proper handling and application.

- Surface Preparation: Thoroughly clean and prepare the surface for PEP™ code application, removing contaminants and addressing defects to promote optimal adhesion.

- Test Compatibility: Conduct a small-scale test application of PEP™ code on a sample area to verify compatibility and desired results with the substrate.

- Follow Mixing Instructions: Adhere to recommended mixing ratios for epoxy resin and hardener components, ensuring accurate blending for desired properties and performance.

- Use Professional-grade Equipment and Tools: Utilize high-quality equipment suitable for epoxy coatings, including brushes, rollers, sprayers, and mixing devices, to ensure consistent application.

- Ensure Proper Ventilation: Maintain adequate airflow and ventilation during application to facilitate curing and minimize inhalation risks.

- Implement Safety Measures: Provide workers with necessary personal protective equipment (PPE) and follow safety guidelines and regulations for storage, handling, and disposal of PEP™ code and associated materials.

- Train and Educate Workers: Conduct training sessions to instruct contractors and workers on PEP™ code handling and application techniques, emphasizing safety protocols for consistent and high-quality results.

- Communicate with the Manufacturer: Establish effective communication with the manufacturer of PEP™ code, seeking guidance, asking questions, and addressing concerns for successful project outcomes.

Surface Preparation:

- Ensure the substrate is clean, dry, and free from contaminants.

- Repair any cracks or defects and perform surface profiling if needed.

Mixing:

- Thoroughly mix the epoxy resin and hardener components according to the recommended ratio.

- Use a clean mixing container and achieve a uniform consistency.

Application:

- Choose the appropriate method (brush, roller, spray) for applying the PEP™ code.

- Apply an even coat, working in sections, avoiding excessive buildup.

- Use cross-rolling or crisscross brushing for a uniform appearance.

Curing and Drying:

- Allow PEP™ code to cure as instructed, considering environmental conditions.

- Prevent exposure to water or moisture during the initial curing period.

Additional Coats (if applicable):

- Apply subsequent coats after the initial coat has cured to a tack-free state.

- Follow recommended recoating intervals.

Cleanup:

- Clean tools and equipment immediately after use with the appropriate solvent.

Maintenance:

- Regularly inspect the coated surface for damage or wear.

- Clean the surface periodically using mild detergents and non-abrasive methods.

Note: Follow the manufacturer’s specific instructions for best results when applying Polyamine Epoxy Coating (PEP™ code).

- Pre-Application Inspection: Conduct a visual inspection of the substrate for proper preparation.

- Material Inspection: Verify materials meet specifications and are from authorized sources.

- Mixing: Follow recommended ratios and procedures for accurate mixing.

- Wet Film Thickness (WFT): Measure and compare wet film thickness to a specified range.

- Cure Time Monitoring: Monitor and record curing time according to the manufacturer’s recommendations.

- Adhesion Testing: Perform tests to evaluate adhesion strength.

- Visual Inspection: Regularly inspect the coated surface for defects or inconsistencies.

- Dry Film Thickness (DFT) Measurement: Measure and verify dry film thickness meets the specified range.

- Gloss and Color Assessment: Assess gloss level and color uniformity against desired standards.

- Documentation: Maintain detailed records of quality control activities.

- Continuous Monitoring: Implement ongoing monitoring and address deviations promptly.

technical documents

Photo Gallery

Technical documentation request

Frequently Asked Questions

How many components is epoxy flooring made of?

It is made of a combination of two components of solvent-free epoxy resin and hardener or polyamine hardener.

How does epoxy flooring prevent cracks in the entire surface?

Because epoxy flooring is impregnated continuously and without interruption between work, there is no seam or gap in the work surface.

What products do you suggest to replace epoxy flooring with new flooring?

If in a project epoxy flooring has been used as a coating and after a while it is decided to re-cover it, it is possible to use alkyd, phenolic alkyd, alkyd silicon and urethane alkyd, two-component epoxy, polyurethane, acrylic for Reused cover.

What is used to make the paint in the middle epoxy flooring?

Polyamine is used with pigments with high warp and resistance.

Epoxy coating is used for what surfaces?

Epoxy flooring can be used for various concrete, metal and stone surfaces.

What tools are used to impregnate flooring with epoxy flooring?

Rollers, brushes or pistols are used to coat the floors with epoxy.

What colors are available in epoxy flooring?

This product is gray in color and is also available in a variety of colors.

How long does it take for the epoxy floor covering to set?

Epoxy flooring product reaches initial setting between 6-8 hours and final setting after 7 days.

Be the first to review “Polyamine Epoxy Coating”