PRODUCT DESCRIPTION

Harmful environmental conditions pose a significant challenge for various building surfaces and facades, impacting their durability. To counter this, using nano-coatings in building materials offers a simple and cost-effective solution to protect surfaces against damage caused by moisture penetration, environmental pollutants like water and rain, and weathering phenomena. The Nano Acrylic Coating (ANC™ code) is a water-based, nano-technology waterproofing formula to safeguard building facades from adverse environmental conditions and create a water-repellent barrier.

When applied to concrete, stone, and other surfaces, the ANC™ code forms a membrane consisting of millions of microscopic hydrophobic nanoparticles. This membrane effectively prevents the entry of water, dust, and other substances into the substrate, safeguarding the surface from damage caused by water or moisture penetration, such as corrosion, scaling, weathering, freezing, mold growth, and fungus growth.

The Importance of Building Sealing

Proper building sealing is crucial to prevent moisture and dampness issues within the structure. Inadequate sealing not only affects the aesthetic appearance of the environment but also creates an unsuitable living environment. Excessive humidity in walls without proper waterproofing leads to the dissolution of salts in construction materials, resulting in white or flaky surface deposits. These areas become good breeding grounds for bacteria, causing unpleasant odors and potential health risks for residents. Structural components can also deteriorate, including metal corrosion, plaster, lime coatings softening and peeling, and wooden panels swelling and deforming. Implementing effective insulation can significantly reduce the costs associated with repairing and rebuilding damage caused by moisture. Utilizing nano waterproof insulation, such as the Nano Acrylic Coating (ANC™ code), provides an ideal solution to achieve this goal.

Features and Properties of Nano Waterproofing

The ANC™ code is formulated using acrylic copolymers and nano-technology, increasing the lifespan of this nano-coating. Noteworthy features of nano waterproofing include its high penetration power, surface flowability, quick drying or setting time, resistance to harmful environmental conditions, water-based formulation, water repellency, ease of application, and more. This type of waterproofing can be utilized on various surfaces like stone, concrete, etc., and finds wide applications for sealing facades, roofs, floors, kitchens, bathrooms, and other areas. Comparatively, nano sealants like the Nano Acrylic Coating (ANC™ code) offer cost-effective alternatives to traditional materials like bitumen or bituminous waterproofing. Consequently, it is recommended to replace traditional insulation or waterproofing materials with nano-coatings or nano-moisture insulation.

Improved Properties of Waterproof Insulation with Nano-technology

Using nano-technology to produce nano-seals or nano-moisture insulation for building facades, such as the Nano Acrylic Coating (ANC™ code), results in the particles’ nanometer size accurately covering 100% of porous materials below. By penetrating the surface and undergoing drying and final setting, the nano-coating strengthens the surface and protects it against damage caused by freezing and thawing, mold, and organic or inorganic stains. Nano waterproofing products stand out from other waterproofing options as they modify surface properties rather than acting as a protective coating. Molecular bonding ensures the nano-coatings adhere to the surface without altering their appearance, providing a decade-long defense against stains, slogans, weather, and abrasion.

Advantages of Using Acrylic Nano Coating (ANC™ code) Compared to Other Sealing Materials

The use of ANC™ Nano Seal eliminates the need for painting and covering the insulation structure, as it is transparent and reveals the underlying surface. Anyone can apply this seal, eliminating the requirement for specialized expertise and significantly reducing costs. Another notable advantage of Nano ANC waterproof insulation compared to other methods is its compatibility with various surface materials such as stone, wood, metal, cement, and more. Nano insulation deeply penetrates building materials, even in rainy areas, ensuring complete resistance to water penetration.

Unlike bituminous waterproofing, applying Acrylic Nano Coating (ANC™ code) does not involve ignition or heating, simplifying the process and making it easily applicable. The ANC™ Nano waterproofing exhibits high adhesive strength and flexibility, providing long-lasting protection. By creating a waterproof surface, nano insulation prevents moisture from seeping into the structure, making it impermeable.

Furthermore, surfaces treated with ANC™ nano-coating are inhospitable to algae, moss, bacteria, mold, and fungus growth. The coating also acts as a dust barrier, minimizing pollution penetration to zero. Additionally, ANC™ nano-coating demonstrates resistance to sunlight, extreme temperatures, and weather fluctuations, ensuring durability and long-term performance. The manufacturing process of Nano ANC™ waterproofing adheres to strict environmental standards, making it an environmentally friendly choice. Moreover, using this nano acrylic coating (ANC™ code) proves to be cost-effective.

Price of Nano Materials for Building Facades

The price of nano facade materials, including Nano Acrylic Coating (ANC™ code), may vary due to market fluctuations. As a result, it is not possible to provide a single fixed price for nano coatings. For accurate pricing information, we recommend contacting our sales experts at Afzir Retrofitting Company, who can provide guidance and address specific inquiries about the cost of nano coatings.

Method of Using Nano Waterproofing

One of the notable advantages of nano waterproofing is its straightforward application compared to other waterproofing materials. The method of using Acrylic Nano Coating (ANC™ code) is simple:

- Start by thoroughly cleaning the surface of dust, grease, and other pollutants.

- Smooth out any unevenness using sandpaper or suitable tools. If the desired surface is metal, it should be deducted beforehand.

- Ensure that the surface is completely dry and free from moisture.

- Apply the nano-coating using a brush or spray, following the instructions.

- Allow the nano-coating sufficient time to dry thoroughly.

Consumption of Acrylic Nano Coating (ANC™ code)

The consumption of the nano-face coating depends on the type of surface being waterproofed. Each liter of nano waterproofing covers approximately 2 to 3.5 square meters. However, it is essential to consider the specific conditions of the surface, as some surfaces may require a higher amount of nano moisture insulation.

The coverage per liter of Acrylic Nano Coating (ANC™ code) in relation to different surface materials is as follows:

- Concrete or cement surface: 2 square meters

- Brick surface: 2.5 square meters

- Chalk or limestone surface: 2.5 square meters

- Stone surface: 3 square meters

Please note that these figures may vary depending on the characteristics of the surface, and it is advisable to assess the specific requirements before proceeding with the application.

For further assistance and to determine the exact amount of nano-coating required for your project, we recommend consulting our experts at Afzir Retrofitting Company. They can provide personalized guidance based on your specific needs.

In conclusion, the Acrylic Nano Coating (ANC™ code) offers an advanced solution for protecting building facades against environmental damage. Its nano-technology formulation provides exceptional water repellency and long-lasting durability. By utilizing this nano waterproofing technology, you can effectively enhance the lifespan of surfaces, reduce maintenance costs, and ensure a protected and aesthetically pleasing environment for your building.

Features

- Acrylate based nano coating

- Suitable for all types of surfaces

- Based on nano technology

- Contains very fine nano particles with a diameter of 1 to 100 nm

- Water repellency

- Water-based

- Keeping the surfaces clean due to reducing the penetration of pollution

- Easy to apply

- Fast setting

- Resistant to environmental conditions

- Maintaining the breathability of surfaces

- No damage in the freezing and thawing cycle

- Not changing the appearance of surfaces

Applications

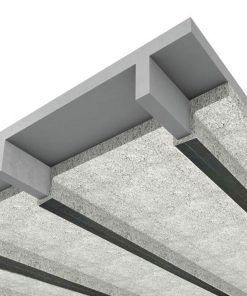

- Suitable for implementation on concrete prefabricated pieces

- Can be used on all granite and ceramic facades

- Applicable on all plaster surfaces

- Ability to waterproof all brick surfaces

- Suitable for waterproofing gypsum panels

- Suitable for waterproofing artificial stone surfaces

- Suitable for waterproofing cement and plaster sculptures

- Suitable for performing on the surfaces of ancient and historical monuments

- Suitable for use on mosaic and concrete wash surfaces

- Applicable on all cement and concrete facades

- Suitable for implementation on concrete prefabricated parts

Packaging

- –

Colour

- White

- Milk White

technical specifications

|

Physical basis |

Milk white liquid |

|

Shelf time |

12 months |

| Maintenance condition |

5-32℃ |

|

chemical basis |

Acrylate-Based |

|

coverage |

Up to 32 m² |

| PH |

6-8 |

- Familiarize Yourself with the Product: Understand the properties and application techniques of Acrylic Nano Coating.

- Conduct Surface Preparation: Ensure surfaces are clean, smooth, and dry before applying the nano-coating.

- Follow Application Guidelines: Adhere to the manufacturer’s recommended temperature, humidity, and application tools procedures.

- Ensure Safety Measures: Wear appropriate PPE and follow handling and storage procedures.

- Test Compatibility and Conduct Trials: Assess performance through small-scale trials and compatibility tests.

- Maintain Quality Control: Regularly inspect coated surfaces for defects and address issues promptly.

- Stay Updated on Industry Standards: Stay informed about the latest standards and technological advancements.

- Collaborate with Suppliers and Peers: Engage in knowledge sharing and networking for professional growth.

- Understand the Product: Familiarize yourself with the properties and guidelines of Acrylic Nano Coating.

- Surface Preparation: Ensure surfaces are clean, contaminant-free, and repaired if necessary.

- Test Compatibility: Conduct small-scale tests to ensure the coating is compatible with the surface.

- Follow Application Guidelines: Adhere to recommended techniques, tools, and environmental conditions.

- Apply Uniformly: Achieve a smooth, even coating across the entire surface.

- Allow Sufficient Drying Time: Follow the manufacturer’s instructions for drying and curing.

- Conduct Quality Control Checks: Regularly inspect for defects and address them promptly.

- Ensure Safety Measures: Provide appropriate PPE and maintain a safe working environment.

- Maintain Proper Storage and Handling: Store the coating correctly and handle it to prevent damage or contamination.

- Communication and Collaboration: Maintain open communication with stakeholders and collaborate for project success.

Surface Preparation:

- Before applying, clean the surface thoroughly by removing contaminants like grease, dust, or paint. Ensure the consistency is completely dry.

- Apply the product within a temperature range of 4-43 degrees Celsius (40-110 degrees Fahrenheit).

- Repair all seams on the surface before proceeding.

Implementation Tips:

- Note that other concrete or stone surfaces may require varying amounts of sealant. Add sealant until further application is not possible.

-

Polished Surfaces:

Apply Nano Band Insulation to a small area, and rub it in circular motions using a clean cloth or lamb’s wool pad until resistance is felt. Repeat this process three times and let the surface dry for an hour. Remove any residue using a dry cloth or polishing pad.

-

Unpolished Surfaces:

Pour nano insulation on the surface and use a 3/8″ (1 cm) nap paint roller or Tufty push broom to press it into the surface. Repeat this process twice for complete saturation. For larger areas, a spray pump can be used.

-

Drying Time:

The initial setting time for the waterproofing is one hour. The application is considered complete after seven days.

Steps to Apply the Coating:

- ANC™ coating is ready to use and can be applied with or without dilution.

- It can be applied using a spray or brush onto the desired surface.

- Once dry, the surface is ready for use.

Product Storage:

- Store the product in dry places, ensuring it remains covered and dry in the environment.

- Maintain a storage temperature between 5 to 32 degrees Celsius.

- Prevent product freezing.

- Seal the container tightly after each use.

- The shelf life of the product is a maximum of one year.

- Inspection of Surface Preparation: Ensure the surface is clean and free from contaminants; address repairs if needed.

- Visual Inspection: Check for uniform coverage and smoothness, and identify defects or uneven areas.

- Adhesion Testing: Assess bond strength between coating and substrate using appropriate tests.

- Thickness Measurement: Measure coating thickness to ensure it meets specifications.

- Surface Hardness Testing: Evaluate the coating’s durability and resistance to impacts or abrasion.

- Water Resistance Testing: Test the coating’s ability to repel water and resist penetration.

- Chemical Resistance Testing: Assess the coating’s resistance to chemicals it may encounter.

- Long-Term Performance Monitoring: Monitor coated surface over time for degradation or issues.

- Documentation and Record Keeping: Maintain detailed records of inspections, tests, and actions taken.

- Continuous Improvement: Use feedback to improve application techniques and enhance overall quality.

- If this product comes into contact with your eyes, immediately open and close your eyes in clean drinking water for 2 minutes.

- Use a mask, gloves and protective glasses while performing.

- This substance is not a toxic and dangerous substance for the environment.

technical documents

Photo Gallery

Technical documentation request

Be the first to review “Acrylate Based Nano Coating”