PRODUCT DESCRIPTION

The Anti-Static Anti-Acid Polyamine Epoxy Coating is an innovative, high-performance solution that provides exceptional protection against static electricity and corrosive environments. When combined with a special hardener, this two-component epoxy resin system forms a durable and resilient coating that safeguards surfaces from damage caused by static discharge and acidic substances.

Formulated with precision, this polyamine epoxy coating incorporates conductive additives, pigments, and anti-acid agents to create a strong and reliable barrier. Its unique composition enables the coating to effectively dissipate static electricity within a wide range of 10,000 to 1,000,000 ohms, minimizing the risks associated with electrostatic discharge.

The Anti-Static Anti-Acid Polyamine Epoxy Coating offers superior anti-corrosion properties, ensuring long-lasting protection for surfaces exposed to harsh and corrosive environments. It acts as a shield against chemical substances that can degrade surfaces and compromise their integrity, thereby extending the lifespan of the coated materials.

In addition to its protective attributes, this epoxy coating also exhibits excellent durability, abrasion resistance, and ease of application. Its robust formulation allows it to withstand the daily wear and tear caused by foot traffic, transportation, and other forms of mechanical stress.

This coating finds numerous applications in environments where the generation of static electricity is a concern, such as laboratories, electronics manufacturing facilities, cleanrooms, data centers, and industrial settings. Moreover, it is particularly well-suited for areas with corrosive agents, including chemical processing plants, storage facilities, and industrial workshops.

The Anti-Static Anti-Acid Polyamine Epoxy Coating not only safeguards surfaces but also contributes to a safer and more efficient working environment by minimizing the risks associated with static discharge and protecting against corrosion. Choose this advanced coating solution to ensure the longevity and integrity of your surfaces in challenging and demanding environments.

Highly recommended for all types of floors, the acid-resistant anti-static floor covering provides comprehensive protection against corrosion and damage. Not only does it safeguard the flooring structure, but it also shields the underlying concrete surface. This coating is an excellent choice for specialized applications requiring anti-static and anti-acid properties.

In terms of compatibility with other protective coatings, if the need arises to recover the floor after initial application, the following products can be used:

- Alkyd, phenolic alkyd, silicone alkyd, and urethane alkyd

- Two-component epoxy

- Polyurethane

- Acrylic

If an additional layer is to be applied immediately after the anti-static anti-acid floor coating, the following protective coatings are suitable:

- Two-component acrylic

- Acrylic latex

- Chloro ruber (Chlorocaoutchouc)

- Polyamide Epoxy High Build

- Two-component polyurethane

Utilizing these compatible coatings maximizes the longevity and performance of the anti-static and anti-acid flooring while ensuring adequate protection against wear and tear.

The global market for Anti-Static Anti-Acid Polyamine Epoxy Coating

The global market for Anti-Static Anti-Acid Polyamine Epoxy Coating is experiencing significant growth, driven by the demand for static control and corrosion protection across various industries. The electronics manufacturing sector and industries requiring static-free environments are key contributors to the market. Regions such as North America, Europe, and Asia-Pacific are witnessing strong growth in this market. Prominent manufacturers invest in research, development, and strategic partnerships to cater to increasing demand. The market is expected to continue expanding due to technological advancements and expanding applications.

Features

- Transfer of static electricity

- Prevent static electricity sparks

Applications

- Anti-acid, anti-static epoxy flooring and concrete protective coating for factories

- Anti-static, anti-acid epoxy flooring for production halls of military units

- Anti-acid and anti-corrosion epoxy flooring for electronic kits and circuits

- Anti-static, anti-acid epoxy flooring for warehouses of flammable materials

- Anti-static, anti-acid epoxy flooring for control rooms

- Protective coating and anti-static anti-acid epoxy flooring of paint mixing rooms

Packaging

- –

Colour

- Black

technical specifications

|

color |

black |

|

Mixing ratio |

A:B= 100:18 |

| density |

1.6g/cm3 |

|

Volume percentage of solid materials |

100% |

| Electrical resistance range |

1MΩ |

|

Initial setting time |

24hours |

| Final setting time |

7 days |

|

Shelf time |

1 year |

| Gel time |

5min |

- Thorough Project Assessment

- Engage with Reputable Suppliers and Manufacturers

- Proper Surface Preparation

- Consider Application Methods and Conditions

- Expert Guidance on Mixing and Curing

- Test and Verify Conductivity Levels

- Provide Maintenance and Cleaning Guidelines

- Stay Updated on Industry Advancements

- Familiarize Yourself with Product Specifications

- Invest in Proper Training

- Prepare the Surface Appropriately

- Follow Mixing and Application Instructions

- Use Suitable Equipment and Tools

- Prioritize Safety Measures

- Conduct Quality Control Checks

- Provide Maintenance Guidelines to Clients

- Maintain Good Communication

Surface Preparation:

- Ensure the surface is clean, dry, and free from contaminants.

- Repair any cracks or defects and apply a recommended primer if necessary.

Mixing:

- Measure and mix the epoxy resin and hardener components accurately.

- Thoroughly mix until a uniform consistency is achieved.

Application:

- Use a brush, roller, or spray to apply the coating.

- Cut in edges and corners first, then apply in smooth and even coats.

- Maintain recommended thickness and coverage, paying attention to high-wear areas.

Curing:

- Allow the coating to cure according to the manufacturer’s instructions.

- Control ambient temperature and humidity within a specified range.

- Avoid stress on the coating during curing and provide ventilation.

Post-Application:

- Inspect the applied coating for uniformity and proper adhesion.

- Perform touch-ups or repairs as needed before full curing.

- Provide clients with maintenance guidelines and cleaning procedures.

Pre-Application Inspection:

Thoroughly inspect the surface for defects and cleanliness before coating application.

Mixing Control:

Follow precise mixing ratios and techniques as instructed by the manufacturer.

Application Inspection:

Monitor the application process for proper technique, coverage, and thickness.

Adhesion Testing:

Conduct tests to assess the bonding strength between the coating and substrate.

Cure Assessment:

Monitor the curing process to ensure proper strength and durability.

Visual Inspection:

Perform a visual inspection to identify any imperfections or defects.

Conductivity Testing:

Measure and verify resistance levels to meet specified requirements for anti-static properties.

Documentation and Record-Keeping:

Maintain detailed records of inspections, tests, and actions taken for future reference.

These eight steps encompass the quality control process for applying Anti-Static, Anti-Acid Polyamine Epoxy Coating, ensuring a high-quality and reliable outcome.

technical documents

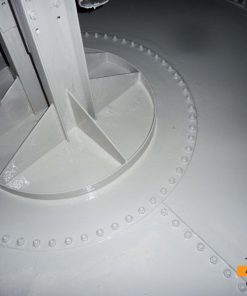

Photo Gallery

Technical documentation request

Be the first to review “Anti Static Anti Acid Polyamine Epoxy Coating”