PRODUCT DESCRIPTION

The Middle Density Spray Applied Fireproof Coating (MDFC™95 code) is an exceptional fire protection solution developed to safeguard steel and concrete structures during fire incidents. Produced by Afzir Company, this innovative water-based medium density fireproof mineral mortar combines refractory minerals, cement, and expanding materials to provide reliable fire resistance.

Designed for both internal and external environments, the Middle Density Spray Applied Fireproof Coating effectively prevents the transmission of heat from fire to the surface of the main material. Its unique formulation incorporates essential components such as vermiculite, dolomite, perlite, light expanding sand, hydraulic mortar (cement), and foaming materials, ensuring optimal performance and durability.

One of the significant advantages of this fireproof coating is its water-based composition, making it highly suitable for application in environments with specific restrictions, such as hospitals. By utilizing this coating, the risk of hazardous emissions during a fire is greatly reduced.

Upon application, the fireproof coating expands, significantly increasing its thickness. This expansion serves as a barrier against the impact of fire, providing enhanced protection to the underlying surface. The Afzir’s fireproof coating not only adds aesthetic appeal but also ensures that no dangerous gases are emitted during fire incidents.

The Middle Density Spray Applied Fireproof Coating offers versatility in its application, making it suitable for use on various surfaces, including concrete, steel, and even wood. With its exceptional fire resistance properties, this coating provides peace of mind by significantly reducing the potential damage caused by fires.

Choose the Middle Density Spray Applied Fireproof Coating for reliable fire protection, ensuring the safety and integrity of your structures in the face of fire emergencies.

Key Features

- High compressive strength

- Excellent performance

- Can be rented in all parts of the structure

- More than 10 years of performance

- Without losing quality over time

Applications

In general, fireproof coating or fireproof mortar can be used in all places where there is a possibility of fire.

- Residential building

- Educational Centers

- Oil and gas refinery

- Petrochemical plants

- industrial centers

- Warehouses and silos

- factories

- Power plants

- Hospital

- Cinema halls

- Entertainment and sports centers

- Marine and oil platforms

- Gas stations

Packaging

- –

Colour

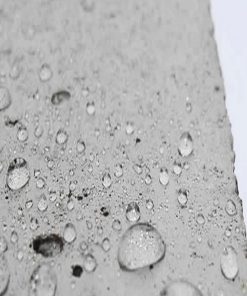

- grey

technical specifications

| color |

grey |

| amount of consumption |

9.5 kg/m2 |

| Shelf time |

15 months |

| Storage condition |

4℃ – 45℃ |

| density |

0.9 kg/cm3 – 0.95kg/cm3 |

| Thermal conductivity |

0.29 W/m oC |

| Compressive strength |

10.6 MPa |

- Familiarize yourself with the product: Understand the properties and characteristics of the Middle Density Spray Applied Fireproof Coating.

- Conduct a thorough risk assessment: Evaluate fire protection requirements and determine appropriate thickness and coverage.

- Collaborate with fire safety experts: Seek guidance from professionals specializing in fire protection systems.

- Ensure proper surface preparation: Clean, dry, and contaminant-free surfaces before applying the fireproof coating.

- Adhere to application guidelines: Follow manufacturer’s instructions on temperature, humidity, and application techniques.

- Regular inspection and maintenance: Periodically inspect and address any damage or deterioration in the fireproof coating.

- Stay updated on industry advancements: Stay informed about new technologies and developments in fireproofing solutions.

- Obtain comprehensive product knowledge: Understand the properties and guidelines of the Middle Density Spray Applied Fireproof Coating.

- Training and certification: Ensure your team receives proper training and certification for application techniques and safety protocols.

- Surface preparation: Clean and prime surfaces according to manufacturer’s recommendations before applying the fireproof coating.

- Adherence to safety protocols: Follow safety guidelines, use PPE, and implement fire safety measures during application.

- Quality control and inspection: Implement a robust quality control process and regularly inspect the coating for adherence and uniformity.

- Collaboration with engineers and designers: Maintain communication with project stakeholders to address specifications and concerns.

- Documentation and record-keeping: Maintain detailed records of application conditions, measurements, and deviations.

- Ongoing communication with the manufacturer: Seek support and guidance from the manufacturer regarding technical inquiries and troubleshooting.

- Surface Preparation: Ensure a clean, dry, and contaminant-free surface. Repair any damage and apply a compatible primer if necessary.

- Mixing: Thoroughly mix the Middle Density Spray Applied Fireproof Coating according to the manufacturer’s instructions.

- Application Equipment: Use recommended airless spray equipment or suitable spray systems. Adjust pressure and nozzle size as per guidelines.

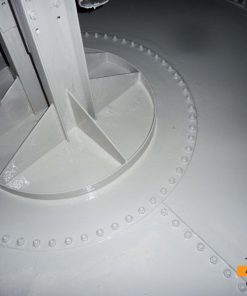

- Application: Apply the coating evenly and uniformly, maintaining consistent spray distance. Apply multiple coats if needed, allowing drying time between coats.

- Finishing: Inspect for and address any irregularities or defects in the coating’s appearance.

- Curing and Drying: Follow the manufacturer’s instructions for curing and drying, ensuring proper ventilation and protection from adverse conditions.

- Inspection and Quality Control: Conduct thorough inspections for uniform coverage and thickness. Address any non-compliance promptly.

- Safety Precautions: Adhere to safety measures, including wearing appropriate PPE and following fire safety and ventilation requirements.

- Pre-Application Inspection: Check substrate cleanliness and condition, and verify ambient conditions.

- Material Verification: Confirm the correct coating product and check batch numbers.

- Application Thickness: Measure and monitor coating thickness using appropriate tools.

- Adhesion and Uniformity: Inspect for proper adhesion and assess coating uniformity.

- Drying and Curing: Follow manufacturer’s instructions for drying and curing, monitoring conditions.

- Post-Application Testing: Conduct additional tests if required by specifications or standards.

- Documentation: Maintain detailed records of quality control activities and deviations.

- Corrective Actions: Address non-compliance promptly, following manufacturer’s guidelines or project specifications.

technical documents

Photo Gallery

Technical documentation request

Frequently Asked Questions

Why is MD mineral base fireproof coating used?

Expandable fireproof mortar based on mineral and cement (code MDFC™95) for the protection of steel and concrete in fire.

What materials does Afzir Company's mineral fireproof mortar contain?

Afzir Company's blue-based medium density mineral fireproof mortar is produced on the basis of refractory minerals and contains expanding materials such as vermiculite, dolomite, perlite, as well as materials such as light expanding sand, hydraulic mortar (cement), foaming materials, etc.

Why is Afzir company's mineral fireproof mortar used for environments with special restrictions?

This type of mortar can be used for internal and external environments of steel and concrete surfaces and prevents the heat caused by fire from reaching the surface of the main material. The blue base of this type of fireproof mortar can help a lot in environments that have certain restrictions (such as hospitals).

How does fireproof mortar work?

After applying the fireproof mortar, the mortar is expanded and its thickness increases to such an extent that the fire has the least effect on the surface under the work.

Can this type of coating be used on wood?

Due to the water base of Afzir's fireproof mortar, it does not emit dangerous gas during a fire. For this reason, this type of insulation can be used on the surface of wood in addition to concrete and steel.

In what colors is the fireproof coating available?

MD mineral base fireproof coating is available in gray color.

What tools are used to implement fireproof coating?

For implementation, it is better to use wet mechanical spray or shotcrete fireproof coating device.

Be the first to review “Middle Density Spray Applied Fireproof Coating”