PRODUCT DESCRIPTION

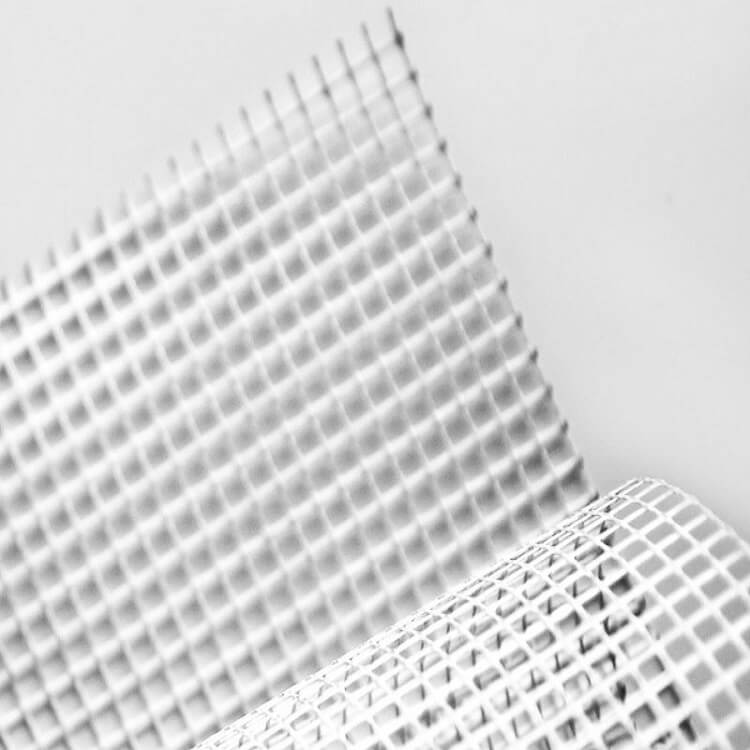

AR Fiberglass Mesh, also known as alkali-resistant fiberglass mesh, is recognized as a resilient type of FRP mesh that withstands alkaline attacks and chemical reactions. This FRP fiber mesh is constructed from a combination of glass fibers and specialized resin, available in various weights and mesh sizes. Consequently, we observe significant differences among the AR fiberglass mesh available in the market based on their specific applications.

AR Fiberglass Mesh maintains its physical and mechanical structure across different environments without experiencing damage, ensuring long-term performance. This innovative product offers high resistance against tension, pressure, heat, moisture, corrosion, and more. It is considered waterproof, fire-resistant, and electrical-resistant. Additionally, it is compatible with various adhesives, including cementitious plaster and gypsum plaster, as well as different types of glues and resins like epoxy, vinyl ester, polyester, etc., allowing for easy installation and application. The alkali-resistant fiberglass mesh is lightweight, flexible and can easily cover and reinforce surfaces of any geometric shape.

Due to its mechanical specifications and unique characteristics, alkali-resistant fiberglass mesh is widely and effectively used in various construction industry applications, particularly in restoring, repairing, and strengthening structures. Its common applications include crack repair, stabilizing plaster and cement, reinforcing stone facades, waterproofing and sealing different water structures, humidity exposure, FRP wall mesh installation, and more. In the following sections, the role of AR fiberglass mesh in each of these mentioned applications will be presented.

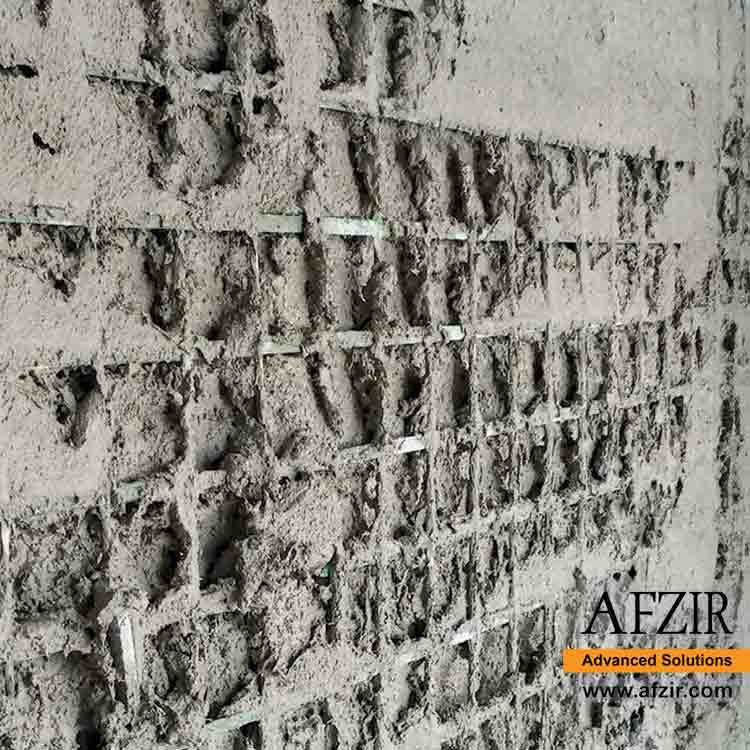

Innovative Implementation of AR Fiberglass Wall Mesh:

Wall Post or AR Fiberglass Mesh is an innovative idea for restraining non-structural walls. Fiberglass mesh, as the main component in this category of Wall Post, independently performs the role of vertical and horizontal metal braces and reinforcing bars in traditional Wall Post with superior performance and behavior. In addition to restraining the components of the wall, AR Fiberglass mesh prevents cracking by providing surface integration of the wall. The superiority of fiberglass mesh over metal has made AR Fiberglass mesh a cost-effective and efficient alternative to traditional (metal) Wall Post.

Crack Control with AR Fiberglass Mesh:

Glass fiber mesh is resistant to alkaline substances and has higher tensile strength than steel and excellent adhesion. When applied to crack repairs, it securely holds the crack in place and prevents its expansion. AR Fiberglass mesh can be used as a reinforcing material during the construction of various surfaces to reduce the likelihood of cracks in susceptible areas significantly.

Plaster Reinforcement:

Fiberglass mesh acts as a supportive or restraining mesh in wall plastering. It enhances the structure’s resistance against cracks caused by shrinkage and settlement of mortar during drying, as well as damages resulting from moisture penetration and environmental factors. Therefore, using AR Fiberglass mesh in plastering significantly increases the structure’s service life and reduces the need for repairs and maintenance.

Reinforcement of Stone Cladding:

Stone cladding is a non-structural element of a building constantly exposed to moisture and adverse environmental conditions, making it highly susceptible to damage. Reinforcing the back of the stone with AR Fiberglass mesh makes it resistant to fractures, cracks, and other damages caused by moisture and environmental factors. Additionally, the fiber mesh behind the stone improves the bond between the stone and the backing mortar, preventing detachment over time.

Insulation and Waterproofing:

AR Fiberglass mesh is waterproof and resistant to alkaline attacks and chemical reactions. Therefore, it can provide good performance as a moisture barrier or waterproofing material in applications such as swimming pools, water structures, and surfaces exposed to moisture. This fiber mesh prevents water leakage.

Reinforcement of Prefabricated Components:

Fiberglass mesh or fiber mesh resistant to alkaline substances increases the tensile and compressive strength, moisture resistance, heat resistance, crack resistance, and other properties of prefabricated concrete components. The use of AR Fiberglass mesh ensures a longer lifespan for the components.

Types of AR Fiberglass Mesh

One of the most important things to consider when buying AR fiberglass mesh is the mesh specifications. The dimensions of the mesh and especially the weight of the glass fibers used in the construction of the fiber network directly affect its specifications. AR fiberglass mesh sizes of 3*3, 4*4, 5*5, 8*8, and 10*10 are common types of AR fiberglass mesh available in the market. In addition to the mesh size, each type of AR fiberglass mesh also has different weights, which will vary depending on the mesh quality. Weights such as 110 grams, 125 grams, 145 grams, and 200 grams are known for being alkali-resistant AR fiberglass mesh and are primarily specific to the mentioned mesh dimensions. However, due to the wide variety of AR fiberglass mesh available in the market, it is possible to purchase these meshes with more diversity in shape, dimensions, and weight. Some AR fiberglass meshes can even be purchased with weights less than 75 grams. The most important factor to consider when buying alkali-resistant AR fiberglass mesh is the intended use. For example, depending on your application, a 75-gram mesh may be a more suitable option compared to a 125-gram mesh.

Below are some examples of the appropriate use of AR fiberglass mesh based on their weight, provided as a guide:

If you need to use fiberglass mesh for reinforcing decorative building stones in interior facades, you can purchase a 75-gram mesh.

If you need mesh for various building stones, including epoxy stones, you can choose 110-gram meshes.

For suitable use in facade stones, it is necessary to use 125-gram meshes. These meshes have better durability as backer meshes.

If you need to increase the strength of different stones such as marble and granite, you can use 145-gram meshes.

How much does AR Fiberglass Mesh cost?

One common question among buyers of meshes and alkali-resistant AR fiberglass mesh is the cost per square meter of AR fiberglass mesh. Generally, it is not possible to talk extensively about the price of this type of product because various factors can affect the price of AR fiberglass mesh. The type of fiberglass mesh structure, the quality of materials used, and the weight are among the factors that can influence the price per square meter of alkali-resistant AR fiberglass mesh. It is evident that as the weight and gram weight of the alkali-resistant AR fiberglass mesh increase, the cost of the mesh will also increase. The best solution to obtain more information about the price per square meter of AR fiberglass mesh is to visit the Afzir Company’s website and gather information about the cost per square meter of this type of FRP mesh. Afzir Company is known as one of the most specialized references in the sale of various AR fiberglass meshes. You can contact Afzir’s experts for more information about the price per square meter of fiberglass mesh.

Features

- Using E-glass fibers as its basic mesh

- If the ARFM ™ fiberglass mesh is used in an alkaline resistant system, it will have the ability to withstand alkaline environments.

- High strength and durability of fiberglass mesh

- Light weight

- Variation in mesh spring and weight distances

- Ease of use

- High cost-effectiveness.

- Suitable for all kinds of architectural elements with different shapes and dimensions

- High flexibility

Applications

ARFM ™ fiberglass mesh is known as a widely used product in the construction industry due to its features such as long life in addition to strength and resistance. Among them are:

- Use in FRCM composite system to strengthen the building

- Replacement of traditional Wall Post

- Strengthening and stabilizing sealing and insulation in pools, reservoirs, etc.

- Stabilization of walls

- A good alternative to metal mesh under the roof

- Stabilizing the facade of the building and creating a suitable platform for installing tiles, mosaics, etc.

- For wall plastering

Packaging

- ARFM ™ fiberglass mesh is produced in the dimensions of 4×6, 2.5×2.5, 5×5 and 3×3 square inches and weighs of 110, 125, 145 and 200 grams, respectively.

Colour

- White

technical specifications

| Specification |

AR fiberglass mesh |

| color |

white |

|

Weight per unit area |

60-200g/m2 |

|

Mesh size |

4*4 5*5 7*9 10*10 |

Refer to the technical data sheet of the product.

Alkali-resistant AR fiberglass mesh demonstrates high resistance against chemical reactions, substances, and corrosive environments. The advantages of using this type of fiber mesh are widely observed in various applications. The superior benefits of AR fiberglass mesh compared to steel are restraining non-structural walls and strengthening them against various damages caused by displacements and seismic vibrations. The application of fiberglass mesh as a Wall Post is explicitly mentioned and approved in Appendix no. 6 of Standard no. 2800 and Publication 819. AR fiberglass mesh provides higher strength than steel at a significantly lower weight.

Additionally, AR fiberglass mesh can tolerate much higher temperatures and heat than steel. This type of mesh pattern, made of AR glass fibers, offers high mechanical specifications, short installation time, and cost-effectiveness in structural restoration, repair, and reinforcement applications. AR fiberglass mesh is compatible with various available resins and plasters, enabling its installation with these materials. Alkali-resistant AR fiberglass meshes are available in different mesh sizes and weights in the market. Therefore, employers, designers, and consumers must choose the appropriate mesh size and weight based on their specific application requirements. We recommend employers, designers, and consumers of AR fiberglass mesh consult our Afzir experts for further information and up-to-date pricing on alkali-resistant AR fiberglass mesh or other reinforcement products.

- Familiarize yourself with the properties and characteristics of AR fiberglass mesh.

- Follow manufacturer guidelines for handling, storage, and installation.

- Prepare the surface by ensuring it is clean and free from contaminants.

- Cut and size the mesh accurately according to the intended dimensions.

- Use compatible adhesives, resins, or plasters recommended by the manufacturer.

- Ensure proper embedment of the mesh into the adhesive or plaster.

- Secure edges and overlaps to prevent lifting or separation.

- Perform regular quality control and inspections of the installed mesh.

- Seek professional assistance for complex applications if needed.

- Follow safety guidelines and use appropriate protective gear.

These recommendations will help contractors achieve successful installations and maintain the desired quality and performance of alkali-resistant AR fiberglass mesh.

The alkali-resistant AR fiberglass mesh can be installed using plastering with gypsum or cement and installation with resin. The use of alkali-resistant fiberglass mesh is straightforward. For example, to use it as rebar mesh, you need to cut it to the desired dimensions using a cutter or scissors and prepare it for use. Then, the wall’s surface or the fiberglass mesh’s installation area should be cleaned from any contaminants, such as oil, paint, dust, etc., using a wire brush and grinder.

AR fiberglass mesh is installed in strips or overall in the innovative rebar mesh by applying cement plaster or gypsum plaster. However, some applications, such as reinforcing stone facades, involve using AR fiberglass mesh, which, after preparation, is applied using a specific resin such as epoxy resin. Therefore, the method of installing alkali-resistant fiberglass mesh can vary depending on the application.

- Visual Inspection: Thoroughly examine the mesh for defects and ensure proper labeling.

- Surface Preparation: Ensure the installation surface is clean, dry, and structurally sound.

- Adhesive Compatibility: Confirm that the adhesive or plaster suits the mesh.

- Mesh Embedment: Inspect proper adhesion and coverage without lifting or detachment.

- Overlaps and Joints: Verify alignment, secure joining, and integration of mesh edges.

- Cure and Drying Time: Allow sufficient time for the adhesive or plaster to cure and dry.

- Bond Strength Testing: Conduct periodic tests to evaluate adhesion between mesh and substrate.

- Overall Aesthetic Appearance: Assess the visual quality and look for cosmetic issues.

- Documentation and Recordkeeping: Maintain records of inspections and relevant documentation.

These steps ensure quality control while installing alkali-resistant AR fiberglass mesh, promoting a reliable reinforcement solution.

technical documents

Photo Gallery

Technical documentation request

Frequently Asked Questions

What is the use of fiberglass mesh?

Reinforcing fiberglass mesh is ideal for use in building construction, mainly for reinforcing concrete, cement, flooring, rendering, covering drywall joints, cracks and holes in drywall, plasterboard, stucco and other surfaces.

What is the characteristic of fiberglass mesh?

Fiberglass mesh has features such as flexibility, proper adhesion, high tensile strength, resistance to the corrosive environment of concrete and cement, etc.

What is the unit weight of fiberglass mesh?

The unit weight of fiberglass mesh is 60 to 200 grams per square meter.

Fiberglass mesh network is protected with what materials?

After production, the fiberglass mesh network should be covered with anti-alkali materials AR (resistant to alkaline environment).

What is the advantage of fiberglass mesh compared to steel mesh?

Low specific weight at the same time high tensile strength.

Be the first to review “Alkali Resistant Systems Mesh Fabric”