PRODUCT DESCRIPTION

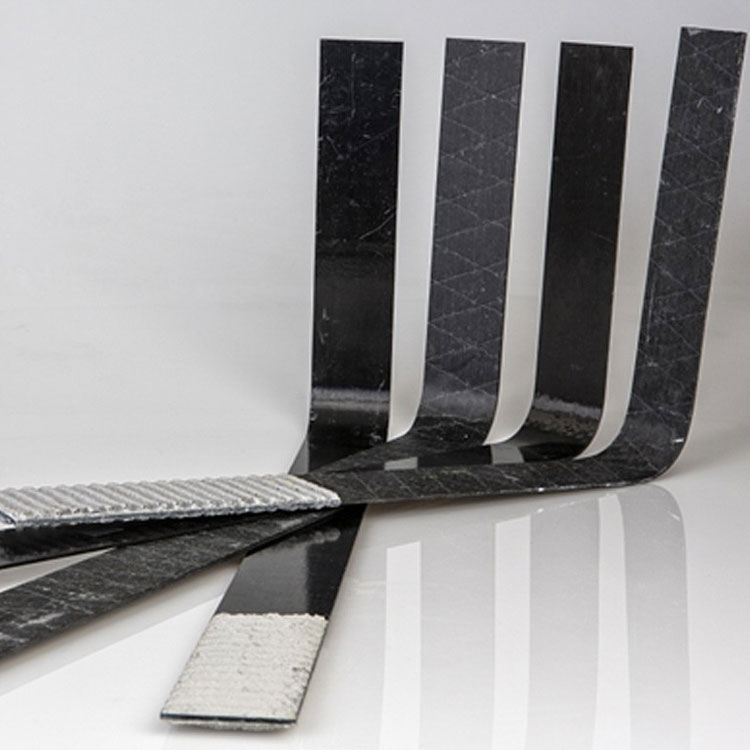

The Afzir LUCL™ L-shaped UD carbon laminates or plates offer a versatile solution for strengthening and reinforcing various structural components. Designed with high-strength carbon and epoxy materials, these prefabricated laminates provide exceptional durability and reliability.

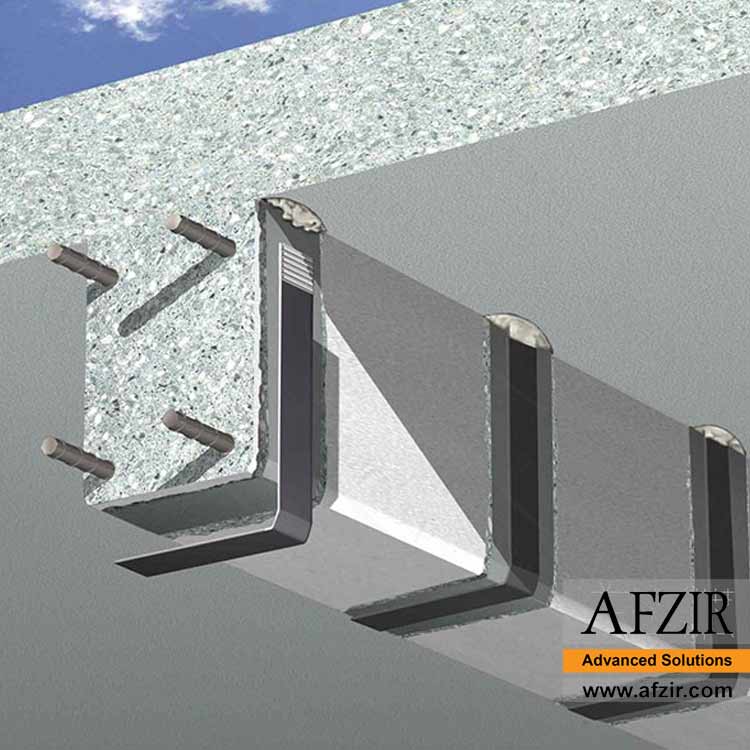

Incorporating LUCL™ laminates as outer bond reinforcements significantly improve the shear strength and stiffness of concrete, stone, and wood elements. This enhances the components’ overall structural integrity and load-bearing capacity, making them more resilient and capable of withstanding heavy loads and forces.

The installation process is straightforward, using a two-part, 100% strong, high-strength structural adhesive system. This adhesive ensures a secure and long-lasting bond between the laminate and the structural members. Compared to traditional steel reinforcements, these carbon laminates offer distinct advantages. They are lightweight, resulting in reduced additional loads on the structure, and they are non-corrosive, eliminating the risk of rust and corrosion-related issues.

Another notable advantage of the Afzir LUCL™ laminates is their ease of installation. Unlike steel reinforcements, which often require complex and time-consuming installation procedures, these laminates can be easily affixed using the adhesive system. This saves time, reduces labor costs, and minimizes disruptions to ongoing construction or renovation projects.

Furthermore, the lightweight nature of carbon laminates simplifies handling and transportation, making them an attractive choice for projects where logistical challenges are a concern.

Overall, the Afzir LUCL™ L-shaped UD carbon laminates offer a reliable, efficient, and cost-effective solution for reinforcing and strengthening various structural components. With their exceptional performance, ease of installation, and durability, these laminates contribute to the longevity and safety of various construction projects.

What is determined the purchase price of L-shaped UD carbon laminates?

Multiple factors determine the purchase price of L-shaped UD carbon laminates. These include the cost of materials such as carbon fiber and epoxy resin, the manufacturing process’s complexity, the order’s quantity and scale, any customization requirements, the quality and certifications of the laminates, and supplier and market-related factors. Considering these aspects is crucial in assessing the pricing and finding an appropriate balance between cost, quality, and specific project needs.

Key Features

- Corrosion resistant

- Very high resistance and durability

- Reinforcement of cutting and breaking

- Appropriate ability

- light weight

- Low overall thickness, can cover more.

- Easy transportation

- Easy installation – no need for installation and carrying equipment

- Outstanding resistance

- Minimal preparation is required for shear fasteners

- Less damage to the beauty of the structure

Applications

- L-shaped carbon laminate profiles are utilized to enhance structural performance and resistance in various applications, including:

- Increasing beam bearing capacity

- Minimizing width of concrete cracks

- Stress reduction in steel reinforcement

- Improved fatigue resistance

- Facilitating structural system modifications

- Removing walls or columns

- Creating access and openings by removing floor and wall sections

- Rectifying design or construction errors

- Adjusting design philosophy to meet specific requirements

Packaging

- Long leg length: 500-1500 mm

- Short leg length: 200-800 mm

Colour

- Black

technical specifications

| specification | L-shaped carbon laminate |

| density | 1.55 g/cm3 |

| color | black |

| Long leg length | 500-1500mm |

| Short leg length | 200-800mm |

| thickness | 2mm |

| width | 50mm |

| specification | 2400MPa |

| Tensile modulus | 131GPa |

| Elongation | 1.87% |

| Fiber volume fraction | 70% |

| Matrix type | Resin epoxy, vinyl ester |

Here’s a summarized list of tips for engineers working with L-shaped carbon laminates:

- Familiarize yourself with product specifications.

- Conduct a thorough structural analysis.

- Collaborate with reputable material suppliers.

- Ensure compatibility with existing structural elements.

- Follow proper installation techniques and guidelines.

- Implement quality control and inspection processes.

- Monitor and assess performance over time.

- Stay updated with industry trends and advancements.

These tips will help engineers effectively utilize L-shaped carbon laminates to enhance structural performance and ensure successful project implementation.

Here’s a summarized list of tips for contractors working with L-shaped carbon laminates:

- Understand the design intent and specifications.

- Coordinate with engineers and suppliers.

- Ensure proper surface preparation.

- Follow the manufacturer’s installation guidelines.

- Train and educate workers on installation techniques.

- Implement quality control measures.

- Maintain documentation of the installation process.

- Collaborate with engineers during testing.

- Address safety considerations throughout the installation.

These tips will help contractors install L-shaped carbon laminates effectively, ensuring compliance with design requirements, high-quality work, and a safe working environment.

Surface Preparation:

- The surface where LUCL-shaped laminates are installed should be clean, healthy, and frost-free.

- Before installation, remove all dust, weak layers, oil, and other destructive substances from the concrete surface.

- Patch large holes using an approved repair mortar.

- The adhesion strength of the concrete can be confirmed by an engineer’s opinion after surface preparation using a pull-off test. The minimum tensile strength should be 1.3 MPa, and the minimum compressive strength should be more than 17 MPa.

Cutting:

- Use a double-sided saw with a shredder or serrated blade to cut the sheets to the appropriate length.

Epoxy Adhesive:

- Epoxy EPT™ 10020 is recommended for adhering to the laminates.

- Follow the factory specifications for properly mixing the epoxy adhesive to achieve a homogeneous mixture.

Here’s a summarized list of quality control guidelines for L-shaped carbon laminates:

Pre-Installation Inspection:

Verify laminate quality and compliance with specifications.

Adhesive Compatibility:

Confirm adhesive compatibility with laminates and follow the manufacturer’s guidelines.

Surface Preparation:

- Ensure proper cleaning, removal of weak layers, and application of repair mortar.

- Verify a dry, frost-free, and contaminant-free surface.

Adhesive Application:

Monitor even and correct adhesive application following the manufacturer’s instructions.

Alignment and Positioning:

Ensure accurate placement according to design specifications.

Bonding Strength:

Conduct bond strength tests to evaluate adhesive performance.

Visual Inspection:

Regularly inspect for defects, delamination, or uneven bonding.

Documentation and Record Keeping:

Maintain detailed records of inspections, test results, and actions taken.

Ongoing Monitoring and Maintenance:

Continuously monitor laminate performance and implement maintenance plans.

By adhering to these quality control guidelines, you can ensure the successful installation and long-term performance of L-shaped carbon laminates in reinforcing concrete structures.

technical documents

Photo Gallery

Technical documentation request

Frequently Asked Questions

What is L-shaped carbon laminate?

L-shaped carbon laminate is almost the same as FRP sheets or laminates made of a combination of unidirectional or bidirectional carbon fibers with glue or resin and with or without a layer of tissue fibers on each side. With the difference that these L-shaped carbon laminations are made up of a 90-degree bend in their longitudinal direction. This type of lamination is mostly used in the corner areas of the sections to be strengthened.

What is the characteristic of L-shaped carbon laminate?

The most important feature and the most important difference between L-shaped carbon laminate and other FRP laminates is the difference in its appearance. This feature has caused these laminates to be able to install in L-shaped areas or corners of structural sections and create a strong conflict between the surface and the laminate. This feature increases the improvement of the mechanical characteristics of sections in such areas. In addition to the mentioned features, L-shaped carbon laminates benefit from other advantages such as high wear resistance, high corrosion resistance, light weight, high durability and stability, high bending strength, high shear resistance, etc.

How can L-shaped carbon laminate be used?

Before installing L-shaped carbon laminations, the desired surface must first be dried using a wire brush, sandblasting, milling and other methods to clean and dry it from any pollution and moisture. Then, the L-shaped carbon laminations should be cut using a saw based on the dimensions of the cross-section or the area to be strengthened. Finally, the surface and laminate are impregnated with resin and the laminate is installed on the surface. Let the resin reach its final setting.

What kind of applications does L-shaped carbon laminate include?

L-shaped carbon laminates are widely used in building retrofitting as retrofitting materials. L-shaped carbon laminate, in order to increase the bearing capacity of beams, reduce concrete cracking, reduce spring, increase shear strength, reduce stress in reinforcing steel reinforcements, increase resistance to fatigue, correct errors in design and implementation, etc. It is applicable.

L-shaped carbon laminate can be installed with what resin?

The best adhesive or resin for the installation and implementation of FRP carbon laminate is special laminate epoxy resin (ERA™420). Because the resin used in the installation of this type of laminations must have the appropriate viscosity to be applied on vertical and sub-series surfaces. In addition, the resin used must be able to establish a strong connection between the surface and the desired laminate. FRP (ERA™420) epoxy laminate adhesive product can be a good choice in such situations.

How is L-shaped carbon laminate made?

In general, L-shaped carbon laminate is made by placing several layers of one-way or two-way carbon fiber fabric on top of each other using adhesive matrices such as epoxy resin, vinyl ester resin in a 90-degree mold with certain dimensions. These L-shaped carbon laminates can be produced using manual layering, machine layering, pultrusion and other methods of making composite products.

Why is the L-shaped carbon laminate made in the form of an English L?

These laminates are usually used for angled surfaces (90-degree angle) and sub-series surfaces of beams and slabs. For this reason, they are made in an L shape to include the members on both sides.

What are the physical characteristics of L-shaped carbon laminate?

The physical appearance of this type of carbon lamination is an L-shaped sheet with a 90-degree angle, which is available in different sizes and thicknesses.

What color is L-shaped carbon laminate?

As you know, carbon fiber is black. For this purpose, the L-shaped carbon laminate is black in color due to the use of carbon fibers as the basic material for making the laminate.

How much is the price of L-shaped carbon laminate?

The price of L-shaped carbon laminate is determined based on the dimensions, the number of layers of carbon fabric fibers and the adhesive matrix used in its construction. L-shaped carbon laminate is sold based on n units of laminates with the same specifications (number = n). Due to the fluctuations in the market, it is not possible to provide a fixed price. For this purpose, you can contact our experts in Afzir to inquire about the exact price of L-shaped carbon laminate.

Be the first to review “L-shaped Carbon Laminate”