PRODUCT DESCRIPTION

Glass fibers are the predominant fibers used in the FRP (Fiber-Reinforced Polymer) industry. UD Glass Wrap is a high-strength glass fabric with fibers oriented in the 0° direction. E-glass fibers are the most widely used in the textile industry and for composite materials and are present in 90% of retrofitting systems. They offer high electrical insulation properties, good thermal resistance, and are cost-effective. S-Glass fibers have higher thermal resistance and about one-third higher tensile strength than E-glass fibers. Specialty AR-glass fibers are specifically resistant to the alkaline environment found in concrete but come at a higher cost.

UD Glass Wrap is lightweight, strong, and less brittle. One of the main advantages of fiberglass is its ability to be molded into complex shapes, which explains its wide use in applications such as bathtubs, boats, aircraft, roofing, and more.

Critical properties of fiberglass include:

Mechanical strength: Fiberglass has higher specific resistance than steel, making it suitable for high-performance applications.

Electrical characteristics: Fiberglass is an excellent electrical insulator even at low thicknesses.

Incombustibility: Being a mineral material, fiberglass is naturally non-combustible, does not support flame propagation, and does not emit smoke or toxic products when exposed to heat.

Dimensional stability: Fiberglass has a low linear expansion coefficient and is not sensitive to temperature and humidity changes.

Compatibility with organic matrices: Fiberglass can be combined with various synthetic resins and mineral matrices like cement.

Non-rotting: Fiberglass does not rot and is resistant to damage caused by rodents and insects.

Thermal conductivity: Fiberglass exhibits low thermal conductivity, making it highly useful in the building industry.

Dielectric permeability: Fiberglass is suitable for electromagnetic windows due to its dielectric properties.

Different types of glass fibers used in various applications include:

- A-glass: Resistant to chemicals, similar to window glass.

- C-glass: Highly resistant to chemical impact.

- E-glass: Known for its electrical properties.

- AE-glass: Alkali-resistant glass.

- S-glass: Utilized for its mechanical properties.

In the construction industry, unidirectional glass fibers are used in precast concrete to delay crack growth and enhance structural integrity. The demand for glass fibers has increased due to their excellent crack resistance, bearing capacity, and tensile strength. Glass fiber-reinforced composites (GFRCs) are used in construction and infrastructure projects to address corrosion issues and reinforce damaged beams, columns, bridges, and other structures.

Fiberglass also plays a significant role in the automotive industry thanks to its high strength-to-weight ratio. Unidirectional GFRPs are utilized as lightweight, high-strength materials in various vehicle components. The dimensional stability, impact resistance, and thermal properties of glass fibers contribute to producing electric vehicles with improved capabilities, strength, fuel efficiency, and extended range.

Furthermore, fiberglass offers numerous advantages in the automotive industry. Its higher strength-to-weight ratio is crucial in automobile manufacturing, allowing lightweight designs without compromising structural integrity. Unidirectional glass fiber-reinforced plastics (GFRPs) are employed in different parts of vehicles, taking advantage of their lightweight nature and high strength. These materials enhance dimensional stability during manufacturing and provide excellent impact and thermal resistance.

The use of fiberglass in automotive applications has several benefits. Firstly, it helps reduce vehicles’ overall weight, improving fuel efficiency and reducing emissions. Additionally, fiberglass components exhibit higher durability and resistance to corrosion, making them suitable for various environmental conditions. The versatility of fiberglass allows for the production of complex shapes and designs, enabling automotive manufacturers to create streamlined and aerodynamic structures.

Moreover, fiberglass contributes to the ongoing trend of electric vehicles (EVs). Due to its lightweight properties, fiberglass helps offset batteries’ weight in EVs, enabling longer driving ranges and increased energy efficiency. Additionally, the electrical insulation properties of fiberglass make it an ideal material for components in electric vehicles, ensuring safety and optimal performance.

The automotive industry continues to explore innovative ways to incorporate fiberglass and other advanced materials into vehicle manufacturing. The ongoing research and development efforts aim to enhance automobiles’ performance, efficiency, and sustainability, further driving the adoption of fiberglass as a critical material in this sector.

Key Features

- Uniform tensile strength and good vertical performance

- Easy impregnation and mold drapability with efficient entrapped air removal.

- High mechanical strength, even in wet conditions

- Excellent electrical insulation properties

- Lower cost compared to carbon fiber

Applications

- Seismic retrofitting and structural improvement of buildings

- Retrofitting of industrial structures

- Reinforcement of pipes and tanks of various types

- Manufacturing of GRP composite parts

- Utilized in the electrical industry as an insulator

- Applied as a coating in the aerospace industry

Packaging

-

Fabric rolls: 500-1000 mm Width and 50000-100000 mm Length

Colour

- white

technical specifications

|

Arial Weight |

200-880 gr/m² |

| Fabric Thickness |

0.16-0.34 mm |

|

Weave Pattern |

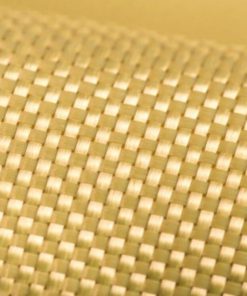

unidirectional |

|

Primary Fiber Direction |

0° (UD) |

|

Width (mm) |

50-100 mm |

| color |

white |

|

Comparison of properties of UD Glass Wrap with conventional construction steel |

||

|

parameter |

unidirectional fiber |

steel |

|

Tensile Strength |

2200 MPa |

360 MPa |

|

Tensile Modulus |

70 GPa |

200 GPa |

| Density | 2550 Kg/m³ |

7850 Kg/m³ |

| Corrosion resistance | Yes |

No |

| Acid resistance | Yes |

No |

The reinforcement of structures is typically carried out to achieve various objectives, including increasing the bearing capacity, addressing corrosion and erosion defects, enhancing structural ductility, accommodating changes in the structure’s use, and compensating for design and execution errors.

Bidirectional glass fibers are highly corrosion-resistant and possess high tensile strength. Their lightweight nature, which aligns with retrofitting goals, has led to increasing utilization of these fibers in seismic retrofitting and improvement projects.

When undertaking reinforcement projects, thoroughly examining the structure’s current condition is essential. This includes assessing the current bearing capacity of elements, identifying defects, reviewing calculation files, and analyzing existing documents and drawings related to the structure.

General principles for the design of UD Glass Wrap reinforcement systems are based on the limit state approach to ensure acceptable performance and safety. Due to the relatively lesser knowledge of FRP composites than other materials like concrete, the application of strength reduction coefficients is necessary, aiming for a design reliability coefficient exceeding 3.5. Additionally, testing methods such as core drilling, compressive strength testing, and ultrasonic testing are employed to measure the properties of existing materials, including compressive strength and modulus of elasticity.

Unidirectional glass fibers exhibit specific behaviors in different loading conditions. Under direct tensile loading, these fibers do not exhibit plastic behavior before failure. The tensile behavior of materials follows an elastic linear stress-strain relationship until sudden failure occurs. Factors such as fiber type, orientation, and quantity play significant roles in determining FRP composites’ tensile strength and hardness.

Regarding compressive behavior, UD Glass Wrap, primarily used as an outer covering, should not be relied upon as compression reinforcement. However, in columns, the confinement behavior of compressive-resistant fibers indirectly contributes to an increased capacity of the column.

Evaluation and acceptance of FRP systems involve assessing factors such as fiber direction, presence of layer separation, adhesion to the surface, layer location, and compliance with design drawings. A supervisory body typically performs these evaluations.

To ensure proper usage of unidirectional glass fibers in projects, control measures should be implemented based on laboratory information provided by the supplier company. Once installed, the strength of CFRP composites is evaluated through tests like the adhesive tensile test (Pull-Off test) conducted on core samples. The adhesive resistance must exceed 1.4 MPa to prevent separation and rupture in concrete. Inadequate strength or separation from concrete indicates system defects and a failure to achieve the expected performance.

Evaluation and approval of installed fibers should consider additional factors, including the occurrence of separation, adherence to specified layer placement direction (with deviations of even 5 degrees impacting resistance), thickness after resin curing, and fiber splice length.

Rehabilitation objectives

Glass fibers have been extensively used in various industries. Their mechanical properties are comparable to carbon fibers and polymers.

In general, the purpose of reinforcement is to enhance the structural capacity to withstand different forces, particularly earthquakes. However, reinforcement is not limited to earthquake resistance and can also address issues like building change of use and material quality deterioration.

Building retrofitting can be categorized into two types:

- Existing and in-use buildings

- Earthquake-damaged buildings

Due to the high cost and time required for demolishing and replacing existing buildings, the importance of building retrofitting has been steadily increasing.

Requirements for building retrofitting

The following scenarios necessitate the development and implementation of retrofitting plans:

Existing damage in old buildings

Common forms of damage in buildings include honeycombing, abnormal cracks, and corrosion in beams, columns, and roofs. Detecting such issues often requires various concrete testing methods, such as coring and rebar scanning.

Execution errors

Retrofitting experts need to investigate errors that occur during the construction phase. These errors can manifest in different ways, such as weak concrete specimens, inconsistency between design strength and actual strength, beam and column buckling, and honeycombing.

Change of building use

Changes in building usage require thorough examination by experts. Altering a building’s purpose introduces new forces on structural members that were not originally designed to bear them. These changes may lead to severe damage and failure in load-bearing elements like beams and columns. Consulting engineers with experience in evaluating existing structures and assessing the feasibility of usage changes are essential to develop accurate and detailed plans.

Detecting defects in a timely manner and selecting the appropriate solutions can save significant costs. It is crucial to seek assistance from experienced professionals in this field, as an improper choice of strengthening, repair, or retrofitting methods can worsen the situation.

Unidirectional carbon fiber reinforcement has become increasingly popular due to its high strength, lightweight nature, electrical non-conductivity, cost reduction, and other benefits. Unlike common retrofitting methods such as steel and concrete jackets, which introduce issues like weight gain, architectural changes, disruption to long-term building use, and increased costs, bidirectional carbon fiber reinforcement offers advantages such as corrosion resistance and prevention of recurring problems.

Employers have various retrofitting solutions to choose from, and they must select the most suitable method for their projects.

The implementation details of UD Glass Wrap depend on the structure’s geometry, substrate smoothness, and other factors. The contractor must adhere to the specifications provided by the consulting engineer when using FRP materials. These specifications include fiber type, resin type, number of layers, execution method, and more to ensure proper reinforcement operations.

Steps for implementing UD Glass Wrap:

Concrete repair and substructure preparation:

Before applying the fibers, all defects in the main concrete and underlying concrete that may compromise the integrity of the CFRP composite should be eliminated. Additionally, if rebar corrosion or rust in the concrete is possible, it must be cleaned and repaired.

Mixing resins:

Resins should be mixed according to the manufacturer’s instructions and project specifications. Proper temperature and quantity should be maintained during the mixing process.

Various methods for installing unidirectional glass fibers:

Once the substrate is prepared, the FRP fibers are installed using different methods specified by the consultant. Here are some installation methods:

a. Unidirectional glass fiber wet gluing system:

This method manually installs the fiber system without any dry or corroded resin. The fibers can be impregnated separately using a resin impregnation device and then applied to the concrete surface.

b. pre-impregnated fiber system:

Unidirectional pre-impregnated systems are resin impregnated at the factory but not cured. These fibers are bonded to surfaces with or without additional resin and cured on-site.

Failure to comply with the instructions provided by the consultant and the manufacturer may weaken the system’s load-bearing capacity and, in some cases, result in fiber separation from the surface. To ensure proper installation, the following should be observed:

Minimize sticking bidirectional glass fibers on the inner surface of corners and ensure sufficient development length.

The overlap should be applied to patched areas.

Following these steps and adhering to the guidelines set by the consultant and manufacturer will help achieve the desired UD Glass Wrap implementation quality.

After implementing the FRP system, it is essential to establish quality assurance and control programs led by the quality control unit (QC). Quality control should encompass a series of necessary inspections and tests.

The quality control inspectors should possess comprehensive knowledge of the FRP system and its installation process. During the installation of the UD Glass Wrap system, they should conduct daily inspections, focusing on the following aspects:

- Ambient temperature, relative humidity, and weather conditions.

- Surface dryness.

- Surface preparation methods.

- Observing the resin curing process.

- Identifying any layer separation, air bubbles, or defects.

- The quality control unit should also conduct periodic inspections and evaluations of the implemented CFRP composite.

Evaluation methods for FRP systems:

General inspections:

Visual inspections examine any changes in color, fiber separation, cracking, or other factors. The presence of such factors indicates weaknesses in the system and improper execution. Surfaces covered with FRP materials should be regularly monitored and inspected, as repairs during operation are uncommon or rare.

Evaluation of concrete composite material separation:

Concrete composite material separation is a critical failure in FRP systems. It renders the FRP system practically inefficient. Pull-off tests should be performed at regular intervals per regulations to diagnose this condition. If minor damage is detected, such as resin injection, caution should be exercised during repair to prevent further damage. For more significant damage, such as scaling or widespread layer separation, adhesives, and composites may need to be removed. Defective materials should be removed from the concrete surface, and the cleaned area should be recoated with new materials.

Long-term monitoring and inspection:

Like other structural members, the reinforcement system with UD Glass Wrap requires regular monitoring and inspection. For bridges, such measures are typically conducted annually in general and every six years in detail. However, regular inspections of buildings are seldom performed. Building quality control engineers should advocate for regularly monitoring and inspecting reinforced members. CFRP composite reinforced buildings should be subject to regular monitoring and inspection of the reinforced members.

technical documents

Photo Gallery

Technical documentation request

Frequently Asked Questions

What are the advantages of UD Glass Wrap over carbon fibers?

UD Glass Wrap has far fewer mechanical properties than unidirectional carbon fibers. But one of the most striking advantages is that the price of UD Glass Wrap is more reasonable than unidirectional carbon fibers. To this end, fiberglass fabrics have gained more market share. Another advantage of fiberglass is its greater flexibility than unidirectional carbon fiber.

What are the suitable resins for gluing UD Glass Wrap on surfaces?

unidirectional glass fibers are well compatible with a variety of adhesives and chemical resins, including FRP epoxy resin, polyester resin and vinyl ester resin, and using them, UD Glass Wrap can be installed on different surfaces.

What are the applications of unidirectional glass fiber?

UD Glass Wraps are widely used in various industries such as seismic retrofitting and improvement of buildings, retrofitting of industrial structures, retrofitting of pipes and tanks, production of composite parts, electrical industries, aerospace industries, etc.

In what dimensions are unidirectional glass fibers available in the market?

In addition, UD Glass Wraps are available in standard sizes of 1270 to 2540 mm.

Which is better, glass fiber or carbon fiber?

Carbon fiber has a higher resistance than glass fiber. So that in some cases it can be used instead of steel. Although glass fibers have lower tensile strength or mechanical properties than carbon fibers, they have a very low tensile modulus. The low tensile modulus of glass fibers makes it easy to bend and withstand higher pressures without breaking.

How is UD Glass Wrap installed on surfaces?

To install UD Glass Wrap on surfaces, the surface must first be cleaned of any contaminants such as oil, paint, dust, etc. Then the relevant resin is mixed according to the manufacturer's instructions and applied to the desired surface using a brush. Finally, the fibrous fabric is cut into desired pieces and placed on the desired surface and impregnated with resin with a roller or brush. This process must be followed for each number of fiber layers. Finally, you must allow the cooking operation to complete.

How are fiberglass composite parts (GFRP) made?

Fiberglass composite parts are made from a combination of fiberglass fabrics with compatible resins. They are made using methods such as manual layering, palletrogen, machine layering, resin transfer molding, pressure molding, etc.

What are unidirectional glass fibers?

In general, unidirectional glass fibers are woven fabrics of fiberglass yarns in which fiberglass yarns are stacked in one direction and in one direction using thin polyester yarns. The combination of these fibrous materials with suitable resins, provides efficient material or materials with high mechanical properties.

What are the weights of UD Glass Wrap on the market?

Unidirectional glass fibers are available in weights of 200 to 1000 grams per square meter.

What is the price of unidirectional glass fibers?

The price of UD Glass Wrap is determined based on the weight and dimensions of the product. Due to market fluctuations, the prices of retrofit products also fluctuate. For this purpose, to inquire about the price of UD Glass Wrap, please contact our experts in Afzir.

Be the first to review “Unidirectional Glass Wrap”