PRODUCT DESCRIPTION

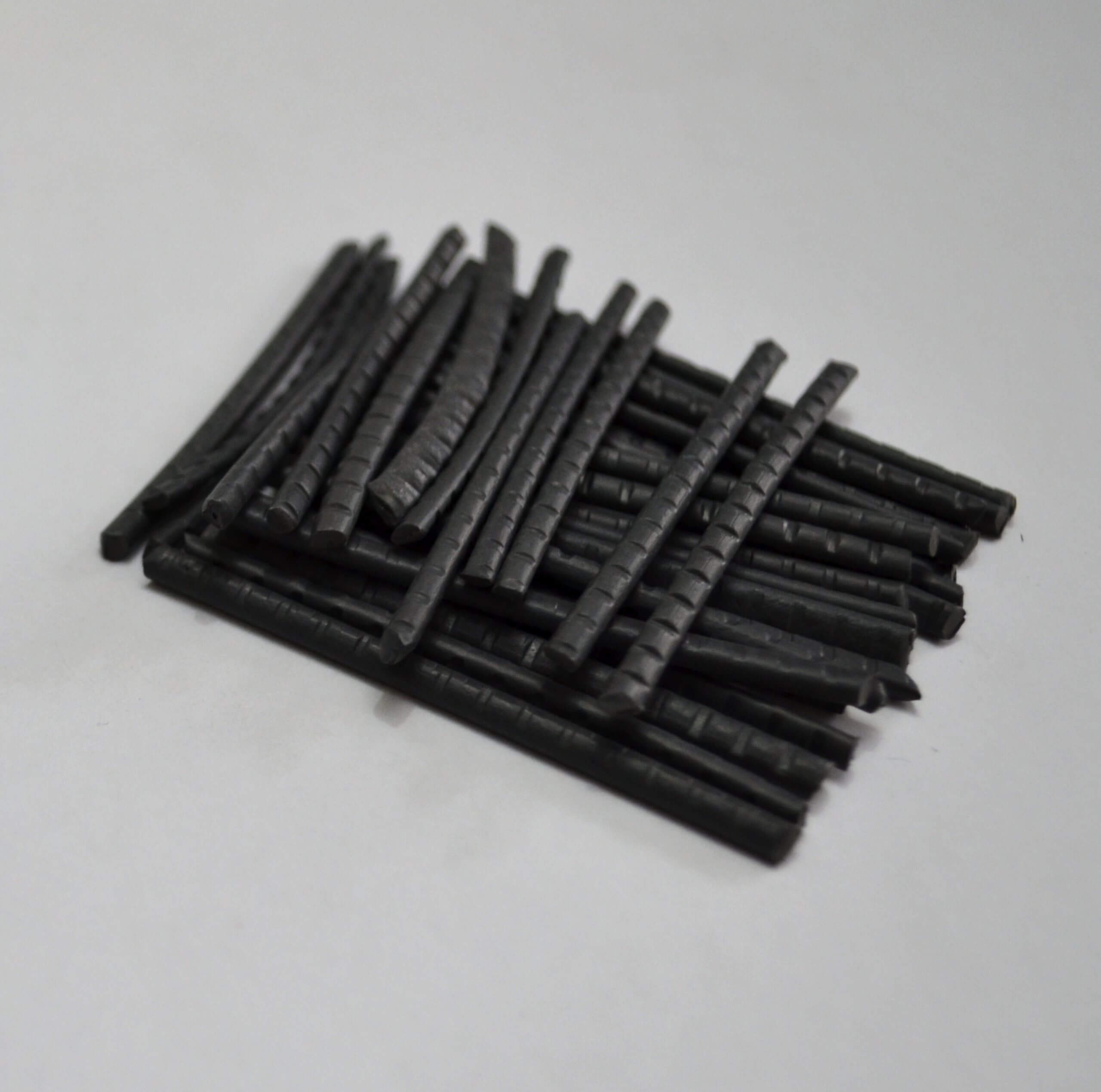

Macro Synthetic Reinforcing Fiber is a specialized product developed by Afzir Company to enhance the performance and durability of concrete structures. These fibers are made from high-strength materials and are designed to be added directly to the concrete mixture during the mixing process. By integrating these fibers into the concrete matrix, the resulting composite material significantly improves strength, crack control, and overall mechanical properties.

The Macro Synthetic Reinforcing Fiber acts as a reinforcement system within the concrete, providing additional strength and toughness.

Unlike traditional steel rebars, these synthetic fibers offer several advantages. Firstly, they are corrosion-resistant, eliminating the risk of rust and ensuring long-term durability. Additionally, their lightweight nature makes them easier to handle and transport compared to heavy steel reinforcement. This feature also simplifies construction by reducing labor requirements and construction time.

Another key benefit of the Macro Synthetic Reinforcing Fiber is its ability to control cracking in concrete structures. The fibers create a three-dimensional network that resists crack formation and propagation by dispersing throughout the concrete mix. This not only improves the overall aesthetics of the concrete but also enhances its durability and resistance to environmental factors such as freeze-thaw cycles and chemical exposure.

The fibers are specifically engineered to provide excellent adhesion and compatibility with concrete. Their natural polymer structure, with propylene bonds, ensures optimal bonding with the cement matrix, leading to enhanced cohesion and overall performance.

The Macro Synthetic Reinforcing Fiber is suitable for a wide range of applications, including but not limited to residential, commercial, and infrastructure projects. It can be used in various concrete elements such as slabs, beams, columns, walls, and precast components. The versatility of the fibers allows for reinforcement solutions to meet the specific requirements of each project.

When considering the cost-effectiveness of the Macro Synthetic Reinforcing Fiber, it offers a compelling advantage. While the initial material cost may vary depending on the project’s scale and requirements, the long-term benefits outweigh the investment. The enhanced strength, durability, and crack control these fibers provide can lead to reduced maintenance costs and extended service life of concrete structures.

Overall, the Macro Synthetic Reinforcing Fiber is a reliable and efficient solution for reinforcing concrete. Its strength, durability, crack control capabilities, and compatibility with various concrete applications offer a sustainable and cost-effective alternative to traditional reinforcement methods.

purchase price of Macro Synthetic Reinforcing Fiber

Available at a competitive price, the Macro Synthetic Reinforcing Fiber offers exceptional value for its performance-enhancing qualities. The pricing of the fibers varies depending on the quantity ordered and specific project requirements. For detailed pricing information and bulk order inquiries, please get in touch with our sales department or visit our website.

Regarding the progress rate, the Macro Synthetic Reinforcing Fiber significantly accelerates the construction process. By reinforcing the concrete and minimizing the occurrence of cracks; it helps improve the overall efficiency of construction projects. The fibers facilitate a faster construction timeline, eliminating the need for additional time-consuming steps such as rebar installation. With the Macro Synthetic Reinforcing Fiber, construction projects can achieve quicker progress without compromising on the strength and durability of the concrete structures.

Features

- Increased tensile, shear, and bending strength of concrete

- Corrosion resistance in concrete

- Enhanced durability and hardness of concrete

- Improved resistance against impact and fatigue

- Increased resistance to thermal stresses and cracking

- Effective control of concrete shrinkage cracks

- Enhanced dynamic resistance of concrete

- Long-term stability of structures

- Improved resistance to seismic loads

- Easy implementation during construction

- Economical alternative to reinforced concrete with traditional reinforcement.

Applications

- Industrial floors of military warehouses, power plants, parking lots and sheds

- Using polymer fibers for existing slabs in residential and commercial structures

- The use of macro synthetic fibers in the concrete paving of airport roads, highways and sidewalks

- Ribbed plastic fibers suitable for concrete shotcrete applications

- Production of reinforced concrete parts with polymer fibers

- As a concrete additive to strengthen and reinforce the concrete walls of tunnels and mining mines

- Can be used in the deck of metal and concrete bridges

- Concreting steel deck roofs

- The ability to produce concrete with high resistance to impact and wear

- Concrete macro synthetic fibers are suitable for mixing in concrete repair mortars

- Macro synthetic polymer is suitable for the concrete of different parts of the structure

- Ribbed plastic fibers are used to produce concrete with high impact and tensile strength

- Construction of reinforced concrete structures with resistant polymer fibers such as military and nuclear structures

Packaging

- depending on the type of application in lengths of 30, 40 and 50 mm

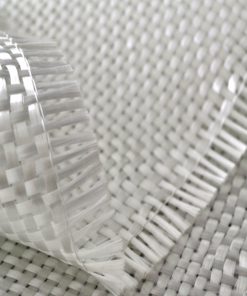

Colour

- white

- Gray

technical specifications

| color |

grey & white |

|

material |

polypropylene |

|

Fiber length |

30,40,50 mm |

| diagonal |

2-3mm |

|

Shelf time |

Two years in original packaging |

|

storage temperature |

5-35 ℃ |

| density |

0.9 g/cm3 |

| tensile strength |

690MPa |

| Alkali resistance |

good |

| Water absorption |

0 |

|

corrosion resistance |

great |

- Familiarize yourself with the product.

- Conduct feasibility studies.

- Collaborate with manufacturers and suppliers.

- Consider design and engineering considerations.

- Implement quality control and testing measures.

- Stay updated with industry standards.

- Collaborate closely with contractors and construction teams.

- Monitor and evaluate performance.

- Engage in continuous learning and improvement.

- Document and share experiences within the engineering community.

- Gain knowledge about the product.

- Collaborate with engineers and designers.

- Plan and budget accordingly.

- Coordinate with suppliers.

- Train your workforce.

- Implement quality control during installation.

- Document and communicate procedures.

- Monitor and address concerns.

- Collaborate with engineers for testing.

- Focus on continuous improvement.

- Share experiences and knowledge.

- Adhere to safety guidelines.

Consumption measure:

The recommended consumption of plastic fibers in concrete typically ranges from 1 to 4 kg per cubic meter, depending on the specific application and desired performance. The exact quantity should be determined based on factors such as the intended use of the concrete and the required strength. Careful consideration of these factors will ensure the optimal dosage of Macro Synthetic Reinforcing Fiber for the desired results.

method of using:

Afzir’s concrete plastic fibers are designed to be easily incorporated into the concrete mixture. They can be poured directly into the concrete mixer during or after mixing. To ensure proper integration, it is crucial to perform high-speed mixing for at least 4 to 5 minutes per cubic meter of concrete. This thorough mixing allows the plastic fibers to be uniformly dispersed and effectively combined with the concrete mixture, ensuring they are spread evenly throughout. By following these guidelines, plastic fibers can enhance the concrete structure’s overall strength, durability, and performance.

Preparation:

Take necessary safety precautions and wear appropriate PPE before handling the fiber.

Mixing:

Add the recommended dosage of Macro Synthetic Reinforcing Fiber to the concrete mixer during or after mixing.

Mixing Time:

Conduct high-speed mixing for at least 4 to 5 minutes per cubic meter of concrete to ensure thorough dispersion.

Mixing Speed:

Follow the manufacturer’s instructions for the appropriate mixing speed.

Uniform Distribution:

Ensure the fibers are evenly spread throughout the concrete mixture to avoid clumping or uneven dispersion.

Quality Control:

Implement a quality control process to monitor fiber dispersion and adherence to the recommended dosage.

Placement and Finishing:

Proceed with standard concrete placement and finishing practices.

Testing and Evaluation:

Collaborate with engineers and testing laboratories to evaluate the performance of the reinforced concrete.

Documentation:

Maintain detailed records of the application process for future reference and quality assurance.

Training and Education:

Provide proper training to the workforce and stay updated with industry advancements for improved application techniques.

Establish Quality Control Plan: Develop a comprehensive plan with clear objectives and procedures for quality control activities.

Compliance with Standards: Ensure the Macro Synthetic Reinforcing Fiber meets industry standards and specifications.

Supplier Evaluation: Evaluate suppliers’ reputation and quality assurance processes to choose reliable sources.

Material Inspection: Inspect the Macro Synthetic Reinforcing Fiber for any damage, contamination, or deviations from specifications.

Dosage Verification: Accurately measure and verify the correct Macro Synthetic Reinforcing Fiber dosage in the concrete mixture.

Mixing Quality: Monitor the mixing process to ensure proper dispersion and uniform distribution of the fibers.

Sample Testing: Collect representative samples of the reinforced concrete for laboratory testing of mechanical properties.

Field Testing: Conduct on-site tests to evaluate the performance and durability of the reinforced concrete.

Documentation: Maintain detailed records of all quality control activities, including inspections, tests, and deviations.

Continuous Improvement: Regularly review and seek feedback to identify areas for improvement in the quality control process.

technical documents

Photo Gallery

Technical documentation request

Be the first to review “Macro Synthetic Reinforcing Fiber”