PRODUCT DESCRIPTION

Introducing Water Repellent Nano Coating for Clay Brick (WNCB™ code), an advanced solution designed to enhance the durability and protection of clay brick surfaces. This innovative nano-coating is formulated with cutting-edge technology to provide exceptional water repellency and moisture insulation for building facades.

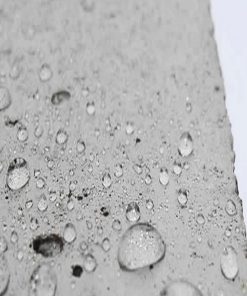

The WNCB™ code features a water-soluble or water-based formulation incorporating specially engineered silicone resins. The hydrophobic particles within the coating are finely dispersed through precise Nano structuring, ensuring uniform coverage and deep penetration into the surface and structure of clay bricks.

By effectively repelling water, this Nano-coating provides a formidable defense against the damaging effects of moisture absorption, chemicals, natural pollutants, and dust. Its waterproof and resistant properties create a reliable barrier, guarding against corrosion, scaling, weathering, freezing, fungal growth, and mold formation. With the WNCB™ code applied, the brick facades of buildings benefit from increased longevity and extended useful life.

Not only does this nano-coating offer exceptional protection, but it also provides self-cleaning properties. The moisture insulation it imparts to the brick facades results in surfaces that stay cleaner for longer, reducing the need for frequent maintenance and upkeep. This self-cleaning capability is especially advantageous in environments with dirt accumulation and atmospheric pollutants.

Applying the WNCB™ code is a hassle-free process that can be easily accomplished using standard application tools such as brushes, sprays, or rollers. Detailed instructions and guidelines are provided in the product documentation, ensuring straightforward implementation by professionals and non-specialists alike.

Choose our Water Repellent Nano Coating for Clay Brick (WNCB™ code) to elevate the performance and protection of your clay brick facades. Experience the benefits of enhanced water repellency, moisture insulation, extended durability, and self-cleaning properties, contributing to your buildings’ longevity and aesthetic appeal. Our dedicated team is ready to provide the support you need for any inquiries or further assistance.

Features

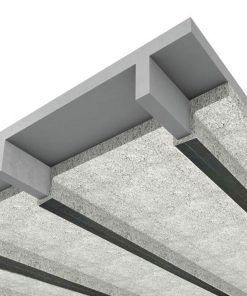

- Suitable for all types of clay brick facades

- Based on nano technology

- Contains very fine nano particles with a diameter of 1 to 100 nm

- Water repellency

- Water-based

- Keeping the surfaces clean due to reducing the penetration of pollution

- Easy to apply

- Fast setting

- Resistant to environmental conditions

- Maintaining the breathability of the brick

- Not changing the appearance of the brick

Applications

- Suitable for all types of clay brick facades, including Kazakh bricks and pressed bricks

Packaging

- –

Colour

- colorless

technical specifications

|

Physical basis |

colorless |

|

Shelf time |

12 months |

| Maintenance condition |

5-40℃ |

|

chemical basis |

Modified Alkaline Silane |

|

density |

1 Kg/L |

| Coverage |

20m² |

- Familiarize yourself with the product: Understand the properties and limitations of the WNCB™ code.

- Conduct surface preparation: Ensure clean and dry clay brick surfaces before application.

- Follow recommended application techniques: Adhere to the manufacturer’s guidelines for tools, coverage rates, and thickness.

- Consider environmental conditions: Consider temperature, humidity, and wind during application and curing.

- Test compatibility and performance: Conduct small-scale tests on representative samples of clay bricks.

- Collaborate with suppliers and manufacturers: Seek technical support and guidance for the specific project.

- Monitor and evaluate performance: Regularly assess water repellency, durability, and self-cleaning properties.

- Stay updated on industry advancements: Keep informed about new research and best practices in nanocoatings for clay bricks.

- Review product documentation: Understand the specifications and guidelines provided by the manufacturer.

- Plan and prepare the project: Assess the scope, timeline, and resources required for implementation.

- Ensure proper surface preparation: Clean and repair clay brick surfaces before applying the coating.

- Test application techniques: Conduct small-scale tests to assess compatibility and desired results.

- Use appropriate application tools: Select brushes, sprayers, or rollers as the manufacturer recommends.

- Consider weather conditions: Account for temperature, humidity, and wind during application and curing.

- Ensure proper ventilation: Provide adequate airflow for proper coating curing.

- Follow safety precautions: Adhere to guidelines and wear the necessary protective equipment.

- Clean tools and equipment: Thoroughly clean materials used for application after completion.

- Communicate with suppliers and manufacturers: Seek support and guidance throughout the implementation process.

Surface Preparation:

- Before application, ensure the surface is free from contaminants such as fat, dust, and paint. It should also be completely dry.

Mixing:

- Mix WNCB™ coating with three parts water.

Steps for Application:

- Apply WNCB™ coating using a spray or brush onto the desired surface.

- Allow the coating to dry before using the surface.

Limitations:

- Once the Nano materials are applied and dried, avoid reapplying them to the surface.

- Ensure thorough coverage and distribution of materials on the surface.

Product Storage:

- Store the product in dry locations.

- Keep the container covered and dry in the environment.

- Maintain a temperature range of 5 to 40 degrees Celsius.

- Protect the product from freezing.

- Seal the container tightly after each use.

- The maximum shelf life of the product is one year.

- Inspection of raw materials: Thoroughly check the quality of raw materials used.

- Batch testing: Test each production batch for consistency and key parameters.

- Adhesion test: Measure the bonding strength between the coating and the clay brick surface.

- Water repellency test: Evaluate the coating’s ability to repel water.

- Durability and weather resistance test: Subject-coated samples to accelerated aging and environmental factors.

- Self-cleaning property assessment: Test the coating’s ability to repel dirt and retain the self-cleaning effect.

- Quality control documentation: Maintain records of tests and corrective actions.

- Continuous improvement: Monitor performance, gather feedback, and implement enhancements.

technical documents

Photo Gallery

Technical documentation request

Be the first to review “Water Repellent Nano Coating for Clay Brick”