PRODUCT DESCRIPTION

The Anti-Static Industrial Polyurethane Flooring (ASPF™ code) is a cutting-edge flooring solution that provides exceptional electrical conductivity and static dissipative properties. Engineered with advanced technology, this flooring system offers superior performance and safety in various industrial and commercial settings.

The key feature of ASPF™ code is its ability to eliminate static electricity generated by foot traffic effectively. By incorporating conductive or isocyanate hardeners, this flooring solution ensures a seamless transfer of static charge, reducing the risk of sparks and electrical discharge. As a result, it finds particular relevance in environments where static electricity can pose a significant safety hazard.

This anti-static flooring system is highly suitable for a range of applications, including ammunition and explosives storage depots, flammable storage areas, electronics industry facilities, control rooms, and paint mixing rooms. Its anti-spark coating properties further enhance safety measures by preventing potential sparks caused by static electricity.

Aside from its exceptional anti-static capabilities, the ASPF™ code also possesses all the desirable qualities and characteristics of industrial polyurethane flooring. It offers outstanding durability, abrasion, and impact resistance, making it suitable for heavy-duty environments. The flooring’s seamless and smooth finish ensures easy cleaning and maintenance, making it ideal for industries with stringent hygiene requirements.

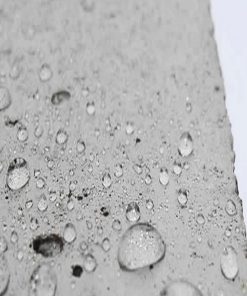

Moreover, the ASPF™ code demonstrates remarkable moisture and heat resistance, making it a reliable choice for environments such as food and beverage processing facilities. It can withstand exposure to various chemicals, making it a preferred option for laboratories and industrial settings where chemical resistance is crucial.

With its high-performance attributes, the Anti-Static Industrial Polyurethane Flooring (ASPF™ code) provides a reliable, long-lasting, and safe flooring solution for industries that demand stringent static control measures and durability. It combines cutting-edge technology with exceptional quality, ensuring a dependable and efficient flooring system that meets the diverse needs of modern industrial environments.

If, in a project anti-static polyurethane flooring has been used as a cover and after a while, it is decided to re-cover it, the following products can be used for recovering:

1. Acrylic: Acrylic coatings provide an alternative cover for anti-static polyurethane flooring, enhancing its durability and appearance.

2. Two-component epoxy: This protective coating offers excellent resistance to chemicals, abrasion, and impact, making it ideal for high-traffic areas.

3. Mastic epoxy: A thicker and more robust option, mastic epoxy coatings provide enhanced protection against heavy-duty wear and tear in industrial environments.

4. Moisture-cure polyurethane: These coatings offer moisture resistance and durability, making them suitable for areas prone to water exposure.

5. Two-component polyurethane: With exceptional chemical resistance and durability, two-component polyurethane coatings provide superior protection against chemicals and abrasion.

6. Two-component organic zinc-rich silicate: This coating type provides excellent corrosion protection, particularly in harsh industrial environments, and offers long-lasting durability.

Each of these products can be used for re-covering anti-static polyurethane flooring, ensuring added protection and meeting specific project requirements.

Key Features

- Transmission of electrical charges

- Prevent possible sparks caused by static electricity

- High abrasion resistance

- High compressive strength

- Resistance to dynamic loads and shock vibrations

- Resistant to tearing and cracking

Applications

- Protective cover for storage of flammable materials

- Protective cover for storage of ammunition and explosives

- Protective cover for military industries

- Protective cover for petrochemical, oil and gas industries

- Protective cover for the electronics industry

- Coverage of industrial and packaging factories

- Protective coverage of the pharmaceutical industry

- Protective cover for the textile industry

- Protective cover for cold storages and slaughterhouses

- Airport protective cover

- Protective cover for workshops and warehouses

- Protective cover for gyms

- Protective cover for hospitals and clean rooms

Packaging

- –

Colour

- Gray (Available in other colors)

technical specifications

| color |

Gray (Available in other colors) |

|

Mixing ratio |

A:B=100:20 |

| Density |

1.5 g/cm3 |

| Optimal thickness |

1000 μm |

| electrical resistance |

1 MΩ |

|

Gel time |

5 minutes |

| Initial setting time |

24 hours |

| Final setting time |

7 days |

| Pot life |

1 year |

- Understand the specific requirements: Gain a thorough understanding of the project’s needs and the environment to address static control, industry regulations, and other challenges.

- Consult with experts: Seek expert guidance from specialists or suppliers in anti-static flooring systems.

- Conduct proper substrate preparation: Prepare the concrete substrate adequately to ensure a sound foundation for the flooring.

- Choose the right product: Select the appropriate anti-static polyurethane flooring based on conductivity, thickness, chemical resistance, durability, and aesthetics.

- Follow installation guidelines: Adhere to the manufacturer’s guidelines for proper installation to ensure optimal performance.

- maintenance plan: Develop a comprehensive plan to preserve the flooring’s longevity and anti-static properties.

- Consider safety measures: Integrate safety measures such as signage, grounding systems, and appropriate footwear requirements.

- Stay updated on industry standards: Stay informed about relevant industry standards and regulations.

- Collaborate with other trades: Coordinate with electrical and HVAC contractors to integrate grounding systems effectively.

- Test and verify performance: Conduct regular testing to ensure the flooring continues to meet desired standards.

- Familiarize with project requirements: Review specifications to understand specific requirements.

- Collaborate with engineers and designers: Communicate and coordinate with project stakeholders to clearly understand design intent.

- Prepare substrate properly: Ensure concrete substrate is well-prepared before installation.

- Adhere to manufacturer guidelines: Follow recommended installation procedures provided by the manufacturer.

- Train and deploy skilled labor: Assign experienced workers trained in polyurethane flooring installation.

- Pay attention to environmental conditions: Monitor and maintain suitable temperature and humidity levels during installation.

- Perform quality control checks: Regularly inspect and verify the quality of the installation.

- Implement proper safety measures: Adhere to safety guidelines and provide necessary PPE and ventilation.

- Coordinate with other trades: Collaborate with other contractors involved in the project for proper integration.

- Provide clear documentation and maintenance instructions: Deliver comprehensive documentation and maintenance guidelines to the client.

- Verify that the substrate is clean, dry, and contaminant-free.

- Follow the manufacturer’s instructions to Apply a suitable primer designed for anti-static polyurethane flooring.

- Mix the anti-static polyurethane coating thoroughly with the recommended mixing ratios.

- Apply the coating using the chosen application technique, ensuring even coverage and uniform thickness.

- Allow the coating to cure per the manufacturer’s instructions, maintaining suitable environmental conditions.

- Optionally, apply additional layers or topcoats as required, following the respective product guidelines.

- Pre-Installation Inspection: Inspect substrate for cleanliness and defects.

- Material Inspection: Check materials for damage or inconsistencies.

- Adhesion Testing: Assess bond strength between substrate and flooring.

- Thickness Measurement: Measure flooring thickness for uniformity.

- Static Control Testing: Verify that anti-static properties meet requirements.

- Visual Inspection: Thoroughly inspect for visible defects and uniformity.

- Abrasion Resistance Testing: Evaluate the flooring’s ability to withstand wear.

- Chemical Resistance Testing: Test resistance to common chemicals.

- Compliance Verification: Ensure compliance with standards and specifications.

- Post-Installation Review: Conduct a final review and address any issues.

technical documents

Photo Gallery

Technical documentation request

Frequently Asked Questions

What are the characteristics of antistatic polyurethane flooring?

Antistatic industrial polyurethane flooring uses an electrically conductive hardener or isocyanate hardener, which allows the static electricity generated by traffic to be transferred.

Does antistatic polyurethane flooring have the ability to conduct electricity?

Yes, it is a feature of antistatic coating to transfer electrical charges.

In what environment is antistatic polyurethane flooring used?

Used in ammunition and explosives storage, flammable storage, electronics, control rooms and paint mixing rooms.

What product is used to replace the new floor covering with antistatic polyurethane floor covering?

Acrylic and epoxy coatings can be used if the project uses antistatic polyurethane flooring as a coating and after a while it is decided to re-coat it.

Why is antistatic polyurethane flooring known as anti-spark coating?

This product is also called anti-spark coating, as it prevents possible sparks from static electricity.

What is the setting time of antistatic polyurethane flooring?

This product reaches the initial setting after 24 hours and the final setting after 7 days.

What is the mixing ratio of the first component with the second component?

The components are combined in a ratio of A: B = 100: 20. In fact, for every 100 components of epoxy resin, 20 components of hardener or hardener are required.

In what colors is antistatic polyurethane flooring available?

This product is available in gray color and can also be offered in other colors.

What tools can be used to apply antistatic polyurethane flooring?

With a roller, brush or pistol, a protective coating can be applied.

Be the first to review “Anti-Static Polyurethane Flooring”