PRODUCT DESCRIPTION

The WNCC™ water repellent nano-coating for concrete and cement is specifically designed for moisture insulation and building facade protection. This advanced coating incorporates modified hydrophobic silanes formulated using cutting-edge nanotechnology. Nano coatings and materials for building facades consist of extremely small particles with diameters ranging from 1 to 100 nanometers. Applying this nano waterproofing coating to concrete and cement surfaces forms a membrane composed of millions of hydrophobic nanoparticles.

The unique nanometer properties of the WNCC™ hydrophobic coating allow for deep penetration into the desired surfaces. This membrane effectively prevents water, dust, pollutants, chemicals, and other substances from entering the concrete. As a result, surfaces treated with this nano insulation are protected from damages caused by water and moisture penetration, such as corrosion, scaling, weathering, freezing, and the growth of fungi and molds. Additionally, these nano-coatings’ dust-repellent and water-repellent properties ensure that the concrete or cement facades always maintain a clean appearance.

Please note that the price of the nanomaterials for building facades, including the nano waterproof coating for cement and concrete (WNCC™), may vary due to market fluctuations. We cannot provide a specific price for each liter of this nano waterproofing product. For accurate and up-to-date pricing information and expert consultation on nano-face materials, nano coatings, nano seals, and more, we recommend contacting our experts at Afzir Collection.

Introducing our Water Repellent Nano Coating for Concrete and Cement, a cutting-edge solution designed to provide unparalleled protection and longevity to building facades. This advanced coating harnesses the power of nanotechnology to create a durable, hydrophobic barrier on concrete and cement surfaces, effectively shielding them from water, moisture, and other damaging elements.

Features

- Suitable for concrete and cement surfaces

- Based on nano technology

- Contains very fine nano particles with a diameter of 1 to 100 nm

- Hydrophobic properties

- Water-based product

- Maintaining cleaning due to reducing the penetration of pollution

- Ease of implementation

- Fast setting

- Resistant to environmental conditions

- Maintaining breathability of concrete

- Not changing the appearance of concrete

Applications

- Facade and concrete surfaces

- Facade and cement pieces

Packaging

- –

Colour

- Colorless

technical specifications

|

Physical basis |

colorless |

|

Shelf time |

12 months |

| Maintenance condition |

4-40℃ |

|

chemical basis |

Modified Alkaline Silicane |

|

density |

1.4Kg/L |

| mixing ratio |

1:30 =A:B |

|

Effective substance content |

52% |

| PH |

13-14 |

- Familiarize Yourself with Nano Coating Technology: Gain knowledge about the principles and applications of nano-coating technology.

- Conduct Comprehensive Surface Analysis: Thoroughly assess the condition and composition of concrete and cement surfaces before applying the nano-coating.

- Optimize Coating Application Techniques: Follow manufacturer guidelines for surface preparation, thickness, and curing to achieve uniform coverage.

- Consider Long-Term Performance: Evaluate the durability, weather resistance, UV protection, and sustainability of the nano-coating.

- Collaborate with Material Suppliers: Engage openly with suppliers for technical support and customized solutions.

- Perform Testing and Quality Control: Implement regular inspections, adhesion tests, and monitoring to ensure compliance with specifications.

- Stay Updated with Advancements: Stay informed about the latest trends and innovations in nano-coating technology through industry events and knowledge-sharing platforms.

- Read and Understand Product Instructions: Familiarize yourself with manufacturer guidelines for application techniques.

- Prepare Surfaces Properly: Ensure clean, dry, and crack-free concrete and cement surfaces.

- Test Compatibility and Adhesion: Perform small-scale tests to ensure proper bonding of the nano-coating.

- Use Appropriate Application Equipment: Select suitable brushes, rollers, or sprayers for even coverage.

- Ensure Ventilation and Safety: Work in well-ventilated areas and wear necessary protective gear.

- Allow Sufficient Curing Time: Follow manufacturer instructions for drying and curing.

- Document and Maintain Records: Keep detailed records of the application process for reference.

- Conduct Quality Control Checks: Regularly inspect coated surfaces for uniformity and adhesion.

Preparation of the Surface:

- Before application, ensure the surface is thoroughly cleaned of contaminants like oil, dust, and paint. The surface must be completely dry.

Mixing:

- Mix the WNCC™ coating with water at a ratio of 30 parts water to one part coating.

Steps for Application:

- Apply WNCC™ coating using a brush or a sprayer onto the desired surface.

- It is recommended to apply 2 to 4 coating layers to ensure proper penetration into the surface. Avoid reapplying if the surface has already dried.

- Allow the coating to dry completely before using the surface.

Limitations:

- Once the nano-coating has been applied and dried, do not apply additional nanomaterials to the surface.

- Ensure thorough coverage and distribution of the coating on the surface.

- The water used for mixing should not have high hardness.

Product Storage:

- Store the product in dry places, covering and protecting it from moisture.

- Maintain a temperature between 5 to 40 degrees Celsius.

- Avoid freezing the product.

- Seal the container tightly after each use.

- The shelf life of the product is up to 1 year.

- Define Quality Standards: Establish clear criteria for coverage, adhesion, thickness, and performance.

- Conduct Initial Testing: Test a small area before full-scale application to ensure compliance with quality standards.

- Implement Regular Inspections: Monitor coating quality throughout the application process.

- Adhesion Testing: Perform tests to evaluate the bond strength between the coating and the surface.

- Verify Water Repellency: Conduct tests to confirm the effectiveness of the water-repellent properties.

- Evaluate Durability: Assess the coating’s resistance to weathering and critical factors.

- Document and Track Results: Maintain records of inspections, tests, and corrective actions taken.

- Collaboration with Suppliers: Work closely with suppliers to establish quality control protocols.

- Continuous Training and Improvement: Provide training and stay updated on industry advancements.

technical documents

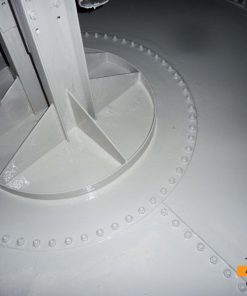

Photo Gallery

Technical documentation request

Be the first to review “Water Repellent Nano Coating for Concrete and Cement”