PRODUCT DESCRIPTION

Is Anti-static Flooring Primer Essential for Preparing the Floor Surface?

Anti-static flooring primer plays a crucial role in preparing the floor surface for flooring installation. Applying a layer of primer or coating to all types of flooring is essential before proceeding with the application process. This layer significantly enhances the durability of the surface by effectively bonding with the concrete substrate. Without the implementation of this primer layer, the flooring’s longevity is compromised, leading to reduced durability.

What are the Advantages of Anti-static Flooring Primer in Concrete Coating?

The application of an anti-static flooring primer offers several advantages, including deep penetration into the concrete, resulting in a seamless concrete coating. Furthermore, this primer aids in aligning the behavior of the concrete and the flooring material, promoting better compatibility and reducing potential issues. Additionally, it enhances the flexibility of the flooring, ensuring it can withstand various stresses and strains.

It’s worth noting that besides the anti-static primer, other primers can be used for lining purposes as well.

How to Choose the Right Primer for Your Flooring Project?

These alternative primers offer different properties and benefits, catering to specific flooring requirements. They may provide enhanced adhesion, moisture resistance, or specific chemical resistance based on the flooring materials and the environment in which they are applied.

What Surface Preparation is Required for Applying Primers?

Choosing the appropriate primer for the specific flooring project is essential to ensure optimal performance and longevity. Factors such as the type of flooring material, the condition of the substrate, and the expected level of wear and tear should be considered when selecting the primer.

Why is Proper Surface Preparation Crucial for Primer Bonding?

The primer application process typically involves thorough surface preparation, such as cleaning, repairing cracks or imperfections, and ensuring proper moisture levels. This preparation is crucial to achieve a solid bond between the primer and the substrate, ensuring the longevity and performance of the entire flooring system.

What Role Does Anti-static Flooring Primer Play in Overall Flooring System Performance?

The use of an anti-static flooring primer, as well as other suitable primers, is a vital step in preparing the floor surface for optimal flooring implementation. These primers contribute to the flooring system’s durability, adhesion, and overall performance. Careful consideration of the specific flooring requirements and proper surface preparation is key to achieving a successful and long-lasting flooring installation.

When considering re-coating a surface previously treated with an antistatic flooring primer, several compatible products can be used for the re-coating process. These include:

1. Alkyd, phenolic alkyd, silicone alkyd, and urethane alkyd coatings.

2. Two-component epoxy coatings.

3. Polyurethane coatings.

4. Acrylic coatings.

In situations where an additional layer needs to be applied immediately after the anti-static floor lining, the following protective coatings can be used:

1. Two-component acrylic coatings.

2. Acrylic latex coatings.

3. Chloro ruber (Chlorocaoutchouc) coatings.

4. Polyamide Epoxy High Build Coatings.

5. Two-component polyurethane coatings.

These compatible coatings provide options for re-coating the surface or applying additional layers to enhance protection and performance further. Following the manufacturer’s guidelines and ensuring proper surface preparation before applying any protective coating is important.

Features

- Static Electricity Dissipation

- Spark Prevention

- Durability and Protection

- Adhesion and Compatibility

- Ease of Application

- Resistance to Chemicals and Stains

Applications

- Protective covering of factories concrete floors

- Protective cover of production halls of military units

- Protective cover of electronic kits and circuits

- Covering warehouses of flammable materials

- Protective cover of control rooms

Packaging

- –

Colour

- Black

technical specifications

|

color |

black |

|

Mixing ratio |

A:B= 100:18 |

| density |

1.2g/cm3 |

|

Gel time |

5 min |

| Initial setting time |

6 hours |

|

Final setting time |

24 hours |

| Shelf time |

1 year |

- Surface preparation: Ensuring thorough surface preparation for optimal application.

- Follow manufacturer’s instructions: Adhering to the instructions provided by the primer manufacturer.

- Test compatibility: Conduct a compatibility test before full-scale application.

- Use proper safety measures: Implementing appropriate safety precautions during handling.

- Consider environmental conditions: Consider temperature and humidity during application.

- Plan for proper coating thickness: Determining and achieving the recommended thickness.

- Monitor curing time: Allow sufficient time for the primer to cure before further actions.

- Maintain proper maintenance: Following maintenance guidelines to preserve the flooring system.

- Familiarize with the product: Understand the primer’s properties and requirements.

- Proper surface preparation: Ensure thorough preparation of the floor surface.

- Follow manufacturer’s guidelines: Adhere to mixing, application, and curing instructions.

- Test compatibility: Perform a small-scale test before the full application.

- Apply primer evenly: Use appropriate techniques for even and consistent coverage.

- Monitor environmental conditions: Maintain suitable temperature, humidity, and ventilation.

- Allow sufficient curing time: Follow recommended curing time before subjecting to use.

- Provide maintenance instructions: Inform clients about proper maintenance procedures.

- Ensure safety: Follow safety protocols throughout the application process.

Surface Preparation:

- Prepare the floor surface by ensuring it is clean, dry, and free from damage or contaminants.

Mixing:

- Follow the manufacturer’s instructions to mix the components of the primer properly.

Application:

- Use the recommended application method (roller, brush, or sprayer) to apply the primer evenly.

- Work in sections and avoid excessive pooling.

Curing:

- Allow the primer to cure according to the manufacturer’s instructions.

- Maintain the specified curing conditions, such as temperature and humidity.

Additional Coatings:

- Apply additional coatings after the primer has fully cured, if desired or necessary.

- Ensure compatibility between the primer and subsequent coatings.

Maintenance:

- Follow the manufacturer’s maintenance guidelines for the primer and any additional coatings.

- Clean the surface using appropriate methods and products.

It is essential to refer to the specific instructions provided by the Anti Static Epoxy Floor Coating Primer manufacturer for detailed and accurate application instructions, as different products may have variations in their application process.

- Inspection of Incoming Materials: Upon receipt, thoroughly inspect the primer materials to ensure they meet requirements and are in good condition.

- Batch Mixing and Testing: Follow proper procedures for mixing primer components and conduct regular batch testing to maintain consistency and verify specifications.

- Surface Preparation: Monitor and verify proper surface preparation, including cleanliness, dryness, and necessary repairs.

- Application Process: Supervise primer application to ensure even coverage, proper techniques, and absence of defects.

- Cure Time and Conditions: Monitor and adhere to recommended cure time and conditions for optimal primer performance.

- Adhesion Testing: Perform periodic adhesion tests to assess bond strength between primer and substrate.

- Static Control Testing: Utilize appropriate equipment to measure and verify the primer’s static control properties.

- Quality Assurance Documentation: Maintain detailed records of inspections, test results, and corrective actions taken.

technical documents

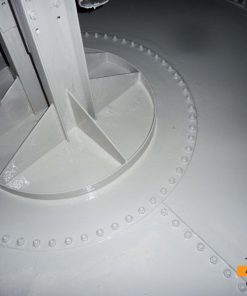

Photo Gallery

Technical documentation request

Be the first to review “Anti Static Epoxy Floor Coating Primer”