PRODUCT DESCRIPTION

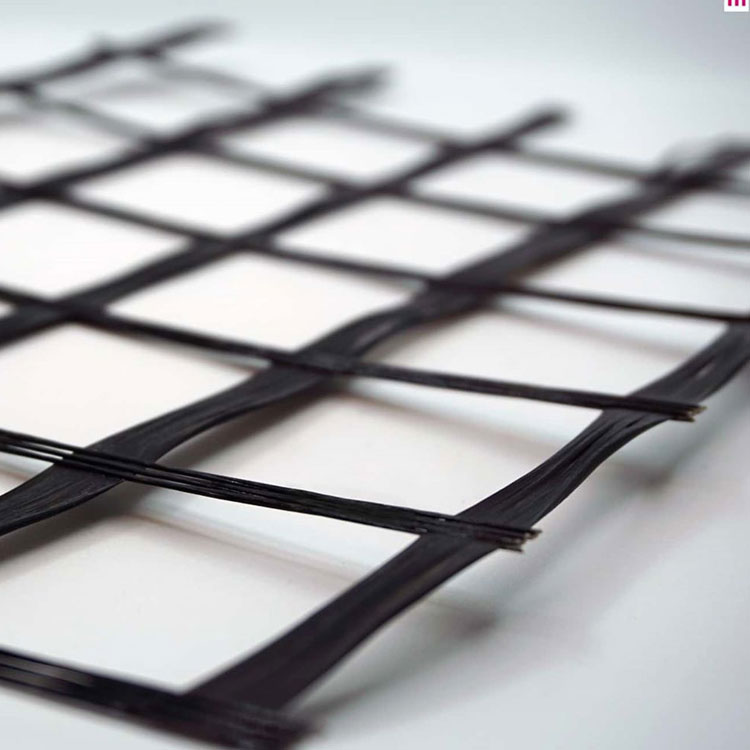

Carbon Fiber Mesh (CFM™) is an advanced construction material that provides high-strength reinforcement for various structures. It is a bidirectional carbon mesh fiber specifically designed to enhance the seismic resistance of buildings and infrastructure. CFM™ is commonly used with cement-based mortar to strengthen reinforced concrete and masonry structures, offering improved safety and performance compared to traditional methods.

The carbon fibers used in its production are lightweight and incredibly strong, offering a high tensile strength-to-weight ratio.

Advantages of carbon fiber mesh:

One of the critical advantages of carbon fiber mesh is its excellent strength-to-weight ratio. It exhibits remarkable tensile strength, allowing it to bear substantial loads and resist deformation. Moreover, carbon fiber mesh is highly resistant to corrosion, chemicals, and UV radiation, making it suitable for various environmental conditions.

Manufacturing Process:

The manufacturing process of carbon fiber mesh involves several steps. First, high-quality carbon fibers are selected and processed to ensure their uniformity and integrity. These carbon fibers are typically coated with a protective layer, such as epoxy resin, to enhance their durability and bonding properties. The fibers are then woven together using advanced techniques, resulting in a strong and flexible mesh structure.

Purchase Price of carbon fiber mesh

The pricing of carbon fiber mesh may vary based on factors such as the quality, size, and quantity required. Additionally, market demand and availability can also influence the price. It is recommended to contact suppliers or manufacturers for specific pricing information.

Rate of Progress and Growth in the Industry:

The carbon fiber mesh industry has experienced significant growth and progress in recent years. The demand for high-strength reinforcement materials in the construction sector, particularly for seismic strengthening applications, has contributed to expanding the carbon fiber mesh market. Technological advancements and ongoing research have further improved the performance and versatility of carbon fiber mesh, leading to its increased adoption in various construction projects worldwide.

Application of carbon fiber mesh in the industry

Carbon fiber mesh finds extensive application in the construction industry, particularly for strengthening and reinforcing structures. It is commonly used in seismic retrofitting projects, integrated with cement-based mortar to enhance the structural integrity and resistance to earthquakes. Carbon fiber mesh provides an effective alternative to traditional reinforcement methods such as steel bars or mesh, offering higher strength, better durability, and reduced weight.

Beyond its seismic strengthening applications, carbon fiber mesh is also utilized in other structural enhancement projects. It can reinforce concrete walls, slabs, beams, and columns, improving their load-bearing capacity and durability. Additionally, carbon fiber mesh is used to repair and restore historical structures, providing a non-intrusive and efficient solution.

The utilization of carbon fiber mesh in the construction industry continues to grow rapidly. Ongoing research and development efforts are focused on enhancing its performance, optimizing manufacturing processes, and exploring new applications. As a result, carbon fiber mesh is expected to play an increasingly significant role in the construction of resilient and durable structures.

Features

- Low weight per unit mesh area

- Easy and flexible installation

- Small installation thickness

- easy to carry

- Easy cutting and molding

- In wet conditions, it is implemented with cement or lime-based concrete repair mortar

Applications

- Increasing shear and bending strength of reinforced concrete beams

- Increasing the bending strength of reinforced concrete slabs

- Increasing the shear strength of reinforced concrete walls

- Improving the ductility and resistance of masonry walls

Packaging

- CFM ™ carbon mesh is produced in dimensions of 1.5*1.5, 4*3.54, 2.95*2.95 and 2.36*2.36 square inches and in weights of 65, 100, 130 and 200 grams respectively.

Colour

- Black

technical specifications

| Specification |

Carbon fiber mesh |

|

color |

black |

|

Weight per unit area |

65-200g/m2 |

|

Mesh size |

1.5*1.5 4*3.54 2.95*2.95 2.36*2.36 |

Refer to the technical data sheet of the product.

- Stay updated with design codes and guidelines.

- Conduct a thorough structural assessment before applying carbon fiber mesh.

- Develop a detailed strengthening plan, considering load transfer and compatibility.

- Ensure proper surface preparation for strong bonding.

- Implement rigorous quality control measures throughout the reinforcement process.

- Seek expert advice for complex structural challenges, if needed.

- Document and evaluate the performance of carbon fiber mesh over time.

By following these recommendations, engineers can effectively utilize carbon fiber mesh to strengthen structures and ensure optimal performance.

- Familiarize yourself with design codes and guidelines relevant to carbon fiber mesh installation.

- Collaborate closely with the engineer to understand the specific project requirements and reinforcement strategy.

- Ensure proper surface preparation, including cleaning and roughening, to facilitate strong bonding of the carbon fiber mesh.

- Adhere to quality control measures and follow recommended installation techniques to ensure the proper application of carbon fiber mesh.

- Use compatible adhesives or mortar systems as specified in the project plan.

- Pay attention to safety protocols and ensure the installation team is properly trained and equipped.

- Maintain clear documentation of the installation process, including any deviations from the original plan.

- Conduct regular inspections during and after installation to verify the quality of workmanship.

- Communicate any challenges or issues encountered during the installation process to the engineer for prompt resolution.

- Provide post-installation support and maintenance, if necessary, to ensure the long-term effectiveness of the carbon fiber mesh reinforcement.

Substrate Preparation:

Before installing CFM™ carbon fiber mesh, ensure that the surface of the substrate is thoroughly cleaned and free from any residues such as oil or grease. This is essential to promote optimal adhesion.

Installation:

- Using a trowel, carefully apply the first layer of repair mortar to the desired thickness, ensuring it is up to 3 mm.

- Insert the CFM™ carbon fiber mesh into the first layer of repair mortar, ensuring it is uniformly and securely embedded.

- Apply the second layer of repair mortar, approximately 3 mm, to completely cover and encapsulate the carbon mesh.

Following the manufacturer’s guidelines and recommendations for the specific CFM™ product being used is crucial. Adhering to proper installation techniques and ensuring a clean substrate will help maximize the effectiveness and performance of the carbon fiber mesh reinforcement.

Material Inspection:

- Verify carbon fiber mesh meets specifications.

- Check for defects or irregularities.

Adhesive or Mortar Inspection:

- Ensure quality and compatibility.

- Check storage and shelf life.

Surface Preparation:

- Verify cleanliness and proper preparation.

- Check for surface irregularities.

Installation Technique:

- Monitor accurate and uniform placement.

- Check alignment and positioning.

Adhesion and Bond Strength:

- Perform adhesion tests.

- Measure bond strength.

Thickness and Coverage:

- Measure applied repair material thickness.

- Ensure complete coverage of carbon fiber mesh.

technical documents

Photo Gallery

Technical documentation request

Frequently Asked Questions

What is the use of carbon mesh?

Carbon fiber mesh may be used to reinforce a wide range of concrete, steel and masonry structural elements including columns, beams, slabs, walls.

What are the advantages of carbon mesh?

Low density with high tensile strength and high modulus - resistance to very high temperature in non-oxidizing environment - excellent electrical and thermal conductivity.

What is the advantage of carbon mesh compared to mesh with aramid fibers?

For frost resistance, the reinforcing effect of carbon fiber mesh is better than basalt fiber mesh and better than aramid fiber mesh.

How is the carbon mesh packaging?

CFM ™ carbon mesh is produced in dimensions of 1.5*1.5, 4*3.54, 2.95*2.95 and 3.36*2.36 square inches and in weights of 65, 100, 130 and 200 grams, respectively.

Be the first to review “Carbon Fiber Mesh”