PRODUCT DESCRIPTION

Super laminates represent a significant leap forward in the field of FRP (Fiber Reinforced Polymer) products, marking a substantial development since the introduction of FRP in the construction industry two decades ago. These laminates effectively address the limitations of conventional laminate strips, offering solutions to long-standing challenges within the construction sector. In fact, some applications were only feasible with super laminates.

The production process of super laminates involves the utilization of specially-designed equipment. Carbon or glass fabric sheets, measuring up to 60 inches (1.5 m) in width, are saturated with resin and then subjected to a press that applies consistent heat and pressure to create the laminates. This method ensures uniformity and precision in the manufacturing process.

The outstanding flexibility of super laminates is showcased by their ability to be coiled into smaller diameters, as well as by their ease of folding, even in the case of large carbon panels. Furthermore, the production of super laminates can adhere to the highest quality standards, with ISO 9000 certification, thus contributing to the broader acceptance and adoption of FRP products in construction projects.

Overall, super laminates represent a significant advancement that addresses previous limitations and opens up new possibilities for applying FRP materials in the construction industry.

Factors Affecting the Price of Super Laminates in the Construction Industry:

- Raw Materials: Fluctuations in the cost of carbon or glass fibers and specialized resins used in production.

- Manufacturing Process: Complexity and efficiency of the manufacturing process, including advanced equipment and technologies.

- Quality and Certification: Compliance with rigorous quality control standards and certifications like ISO 9000.

- Market Competition: Competition among manufacturers and suppliers offering similar products.

- Application and Demand: Specific applications and demand for super laminates in the construction industry.

- Economy and Inflation: Economic factors such as inflation rates and currency fluctuations impact raw material costs and production expenses.

Super laminates represent a significant advancement in the FRP industry, overcoming the limitations of conventional laminate strips. They have opened new possibilities and addressed long-standing challenges in construction. The production process involves specialized equipment, saturating carbon or glass fabric sheets with resin, and subjecting them to heat and pressure for uniformity. Super laminates exhibit exceptional flexibility, allowing for coiling and folding, and can meet high-quality standards with ISO 9000 certification. These factors collectively contribute to the wider acceptance and adoption of FRP products in construction, making super laminates a valuable and innovative solution.

Key Features

- Manufactured with the highest quality control.

- Multiple layers of carbon or glass fiber for increased strength.

- Simultaneous strength and impermeability.

- Installation without the need for digging, utilizing manhole access.

- Anti-corrosion system for withstanding various chemicals.

- Non-toxic and odorless resins for installation in poor ventilation conditions.

- Does not reduce the inner diameter of pipes when composite sheets are used.

- Versatile application methods: single loop and continuous spiral.

Applications

- Pipe Repair

- Tank Repair

- Valve Repair

- Retrofitting

- Waterproofing

- Chemical Resistance

- Industrial Infrastructure

- Construction Projects

Packaging

- Standard rolls of carbon and glass bidirectional fiberglass sheets are available in one meter by two meters.

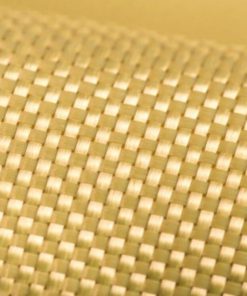

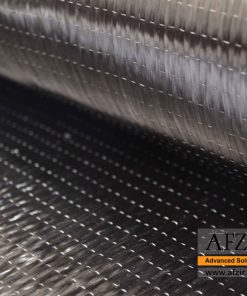

Colour

- Super Carbon Laminate: Black

- Super glass laminated: white

technical specifications

|

Super laminate thickness |

|

| Bidirectional super carbon laminate |

0.66mm |

| Bidirectional super glass laminate |

0.66mm |

Bidirectional super carbon laminate

|

Longitudinal direction of fibers (0 degrees and 90 degrees) |

|

|

Tensile strength |

697 MPa |

| Elasticity modulus |

49.277 MPa |

|

elongation |

0.85% |

|

lateral direction of fibers (90 degrees) |

|

| Tensile strength |

442.6 MPa |

| Elasticity modulus |

20.264 MPa |

|

elongation |

1.42% |

Bidirectional super glass laminate

|

Longitudinal direction of fibers (0 degrees and 90 degrees) |

|

| Tensile strength |

431 MPa |

|

Elasticity modulus |

24.140 MPa |

| elongation |

1.31% |

|

lateral direction of fibers (90 degrees) |

|

| Tensile strength |

418 MPa |

| Elasticity modulus |

20.25 MPa |

| elongation |

1.06% |

Surface Preparation:

Ensure that the surface to be laminated is clean, dry, and free from any contaminants or loose particles. Remove any existing coatings, rust, or corrosion as necessary.

-

Adhesive Selection:

Choose the appropriate adhesive or resin system based on the specific application and requirements. Consider factors such as compatibility with the substrate material, curing time, and desired strength.

-

Mixing and Application:

Follow the manufacturer’s instructions for mixing the adhesive or resin components. Apply the adhesive evenly onto the surface using a suitable application tool, ensuring complete coverage.

-

Lamination:

Carefully place the FRP super laminate onto the adhesive-coated surface. Smooth out any air bubbles or wrinkles using a roller or squeegee, ensuring proper adhesion and contact between the laminate and the substrate.

-

Curing Time:

Allow sufficient time for the adhesive or resin to cure according to the manufacturer’s recommendations. Maintain appropriate temperature and humidity conditions during the curing process.

-

Quality Control:

Regularly inspect the laminated area for defects or issues, such as air pockets, voids, or delamination. Address any concerns promptly to ensure the integrity of the laminate.

-

Finishing and Protection:

Once the laminate is fully cured, consider applying a protective coating or finish to enhance durability, resistance to UV radiation, and ease of maintenance, if required.

-

Documentation:

Maintain detailed documentation of the application process, including adhesive/ resin specifications, curing times, and quality control records for future reference and quality assurance.

- Prepare surfaces properly for optimal adhesion.

- Select compatible adhesives and resin systems.

- Follow the manufacturer’s storage, handling, and installation guidelines.

- Implement thorough quality control and inspection processes.

- Incorporate appropriate structural design considerations.

- Consider environmental factors for material and coating selection.

- Ensure engineers have proper training and expertise.

- Maintain documentation and perform testing for verification.

By following these tips, engineers can work effectively with FRP super laminates and achieve successful and durable installations.

Tips for Contractors Working with FRP Super Laminates:

- Understand the properties and requirements of FRP super laminates.

- Collaborate with engineers and design professionals.

- Provide adequate training and certification for your workforce.

- Prepare the substrate surface properly for optimal adhesion.

- Follow the manufacturer’s guidelines for installation.

- Implement rigorous quality control and inspection processes.

- Prioritize safety when handling FRP materials.

- Maintain effective communication and coordination with stakeholders.

By following these tips, contractors can ensure successful and high-quality installations of FRP super laminates in their projects.

Guide to Quality Control for FRP Super Laminates:

- Establish clear quality standards and specifications.

- Inspect incoming materials for defects and compliance.

- Test and verify adhesive/resin properties.

- Verify proper surface preparation before lamination.

- Monitor and inspect adhesive application for uniform coverage.

- Perform regular visual inspections for defects and irregularities.

- Utilize non-destructive testing methods to detect flaws.

- Conduct adhesion testing to assess bond strength.

- Maintain comprehensive documentation and traceability.

- Implement continuous monitoring throughout the project.

- Ensure compliance with industry standards and regulations.

technical documents

Photo Gallery

Technical documentation request

Frequently Asked Questions

What is Frp Super Laminate?

Frp super laminate is a sheet or laminate consisting of several layers of carbon fiber glass or glass stacked on top of a resin. The low thickness of this type of Frp laminates has greatly increased their flexibility. For this purpose, Frp super laminates can be easily installed around the circular sections and improve their mechanical properties.

What are the features of Frp Super Laminate?

The most important feature of Frp super laminate is its low thickness and good flexibility. This feature allows easy installation and connection of Frp laminate to external or internal aspects of circular sections such as pipes. In addition, Frp super laminates, low weight, high abrasion resistance, high heat resistance, high corrosion resistance, high resistance to chemical reactions, non-toxic, bi-free, high resistance Penetration, very good resistance to constant loads, etc. noted.

What are the components of Frp super laminate?

Frp super laminates, like other Frp laminates, are formed by placing several layers of fibrous fabric on top of a resin. The difference is that the number of layers of fibrous fabrics used in the manufacture of Frp super laminates is less than conventional Frp laminates due to its good flexibility. Super laminates can be produced using glass fibers or carbon fibers by manual lamination, machine lamination, palletrogen or other Frp fabrication methods.

What is the advantage of FRP super laminate over ordinary laminates?

Frp super laminates have a higher flexibility due to their relatively less thickness than conventional Frp laminates. The flexibility of reinforcement materials is an advantage in implementing restoration or reinforcement designs. Because flexible reinforcement products, including Frp super laminates, can well cover the lateral area of sections, especially circular sections, and provide good joints.

What are the applications of FRP super laminate?

FRP super laminate is widely used in various industries. One of the most common applications in the construction industry is the reinforcement of structural elements such as beams, slabs, walls, etc., and in the water and wastewater industry can be the production, repair and reinforcement of pipes, tanks and valves.

What is the best resin for applying and installing Frp super laminate?

As you know, both carbon and glass fibers are compatible with most resins, including epoxy resin, vinyl ester resin and polyester resin. But the best resin must be determined according to the purpose of application. The thickness of Frp laminates is much higher than Frp fiber fabrics. Therefore, the adhesive or resin used in Frp laminates must have good adhesion and saturation strength. Frp epoxy laminate resin (ERA ™ 420) is a suitable choice for installation and implementation of all types of Frp eminences.

How and where to get Frp super laminate?

To obtain Frp super laminate, you can consult with building reinforcement companies or suppliers of reinforcement materials. Afzir Reinforcement Company works in the field of consulting, design, execution and supply of materials required for the implementation of structural and restoration projects of the structure. Our expert experts in the collection are ready to answer you, engineers, employers, contractors and other activists in this field.

At what levels can Frp super laminate be used?

Frp super laminate is compatible with most surfaces of stone, wood, steel, concrete, etc. and adheres well to them. Frp super laminates are also designed to be installed in sections with circular or circular geometric shapes.

Be the first to review “Carbon Super Laminate Plain”