PRODUCT DESCRIPTION

Introducing Speed Plug Powder Waterproof (SPPW™), the ultimate solution for sealing concrete projects. This exceptional product is designed to effectively address and eliminate leakage issues in concrete structures, ensuring long-lasting protection and durability.

Speed Plug Powder Waterproof is available in a convenient powder form, ready to be mixed with water for immediate use. Its fast-setting formula, based on cement, quickly reacts upon contact with water, solidifying in just 20 seconds. This rapid hardening process forms a robust barrier, effectively blocking the passage of water and preventing further leaks.

Ideal for structures experiencing high hydrostatic pressure, such as dams, Speed Plug Powder Waterproof excels at swiftly repairing and fixing leaks. Its remarkable performance surpasses other concrete sealing products, making it the go-to choice for critical applications.

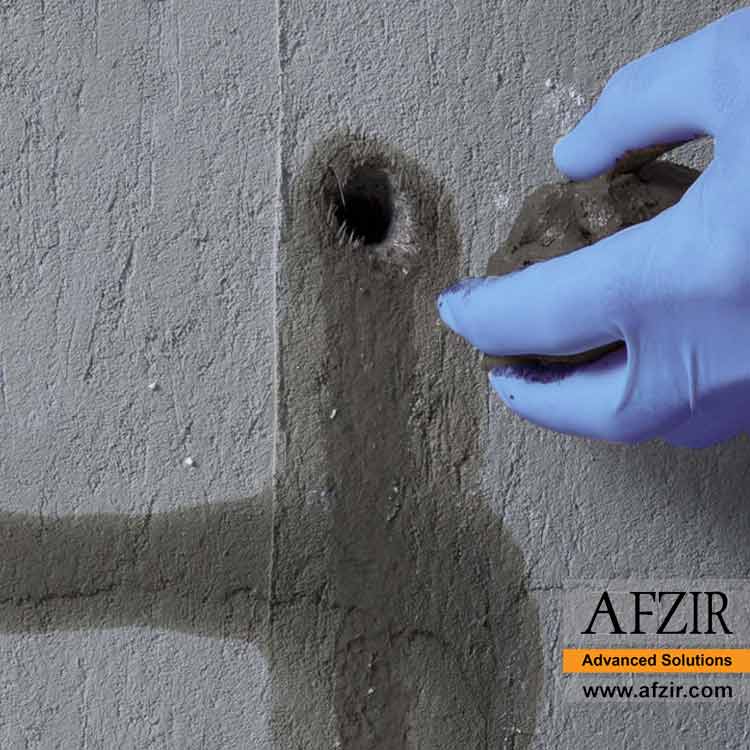

Using Speed Plug Powder Waterproof is straightforward. Begin by opening the leak area in a V-shaped seam, allowing for proper application. If the leakage is substantial, installing a drainage pipe is available for efficient water removal. After thoroughly cleaning and preparing the surface as recommended, apply the prepared mortar immediately by hand, ensuring even coverage. Hand application is preferred for optimal results, though alternative methods like a trowel can also be used.

Preparing an amount of mortar that can be consumed within 20 seconds is crucial, as Speed Plug Powder Waterproof rapidly solidifies once mixed. This ensures maximum effectiveness and avoids wastage of the product.

When a high-water flow and a drainage pipe are utilized, once the leakage is fixed, the pipes should be cut off, and the repaired area should be sealed using instant adhesive mortar, guaranteeing a seamless finish and lasting protection.

The recommended mixing ratio for Speed Plug Powder Waterproof is 1 part water to 3 part mortar. Considering this ratio and the specific weight of the mortar in its paste state, the precise amount required can be determined based on the crack’s volume. As a general guideline, for a square area measuring 1 square meter with a depth of 5 mm, approximately 6 kg of Speed Plug Powder Waterproof should be used.

Choose Speed Plug Powder Waterproof for unmatched reliability, efficiency, and effectiveness in sealing concrete structures. Experience the peace of mind that comes with a superior waterproofing solution that delivers outstanding results every time.

Features

- Without chlorine ion

- Easy to mix with drinking water

- High durability

- High adhesion with concrete

- No seams, hairline cracking and shrinkage

- Fast setting

- Fast operation

- No corrosion of rebars

Applications

- Sealing of tunnels and underground spaces

- Sealing pools and water tanks

- Sealing of channels and ditch system

- Sealing of sewer pipes and manholes

- Sealing of dams

- Sealing the elevator pit

- Sealing of sewage treatment plants

Packaging

- In 20Kg and 25Kg pockets

Colour

- Grey

technical specifications

|

Density |

2.15 gr/cm3 |

| Physical basis |

powder |

|

Setting time |

20 sec. |

| Chlorine |

no |

|

PH |

12 months |

|

Shelf time |

1 year |

| Maintenance situation |

away from cold and frost, heat and direct and long sunlight |

- Thoroughly assess the leakage area before applying Speed Plug Powder Waterproof.

- Follow proper surface preparation procedures, ensuring a clean and dry surface.

- Create a V-shaped seam to enhance penetration and sealing effectiveness.

- Consider drainage options if excessive water flow is present.

- Work efficiently, preparing and applying the mortar in small batches within 20 seconds.

- Apply Speed Plug Powder Waterproof by hand for better control and coverage.

- Adhere to the recommended mixing ratio of 1:3 (water to mortar).

- Use protective equipment for safety during application.

- Monitor and test the repaired area for effectiveness.

- Consult the manufacturer’s technical specifications and guidelines for best practices.

Familiarize yourself with the product and its application requirements.

Conduct a thorough site inspection before starting the application.

Plan and organize the workflow for efficient execution.

Train the workforce on mixing ratios, application techniques, and safety protocols.

Properly prepare the surface by removing debris and ensuring structural integrity.

Adhere to recommended mixing ratios of water to Speed Plug Powder Waterproof.

Use appropriate application techniques for even coverage and compaction.

Monitor and control curing conditions, considering temperature and humidity.

Conduct quality checks and tests to ensure a reliable seal.

Maintain open communication with the project team and address concerns promptly.

- Surface Preparation: Thoroughly clean the surface where the product will be applied. Remove any loose particles, dirt, or contaminants. Ensure the surface is dry before proceeding.

- Leak Opening: If there is a leakage, open the area in a V-shaped seam. This provides a secure space for the Speed Plug Powder Waterproof to be applied and enhances penetration.

- Drainage Consideration: Assess the water flow and determine if a drainage pipe is necessary to handle excessive water runoff. Install the drainage pipe strategically if required.

- Mixing Ratio: Follow the recommended mixing ratio of 1 part water to 3 parts Speed Plug Powder Waterproof. Measure the appropriate amounts to achieve the desired consistency.

- Mixing Process: In a clean container, gradually add the powder to the water while stirring continuously. Mix until a homogeneous mixture is obtained without any lumps.

- Application: Apply the prepared mortar immediately after mixing, within 20 seconds. Use a trowel or apply by hand, ensuring even coverage and proper compaction. Pay special attention to the leak area.

- Consumable Amount: Prepare an amount of mortar that can be consumed within 20 seconds to avoid wastage and ensure workability.

- Curing Time: Allow the applied Speed Plug Powder Waterproof to cure and harden according to the manufacturer’s instructions. Follow the recommended curing timeframes for optimal results.

- Quality Check: Regularly inspect the repaired area for any signs of leakage or defects. Perform appropriate tests to verify the effectiveness of the seal and make any necessary adjustments.

- Communication and Collaboration: Maintain open communication with the project team, including engineers, contractors, and clients. Share progress updates and address any concerns promptly.

- Adhere to manufacturer guidelines and instructions for Speed Plug Powder Waterproof.

- Ensure workers are trained and competent in handling the product.

- Thoroughly inspect and prepare the surface before application.

- Accurately measure and mix the product according to recommended ratios.

- Apply Speed Plug Powder Waterproof using recommended techniques for even coverage.

- Maintain high quality standards during application.

- Adhere to recommended curing and drying times.

- Conduct regular inspections and tests to check for defects or signs of leakage.

- Keep detailed records of the application process for future reference.

- Continuously assess and improve quality control processes for optimal results.

technical documents

Photo Gallery

Technical documentation request

Be the first to review “Speed Plug Powder Waterproof”