PRODUCT DESCRIPTION

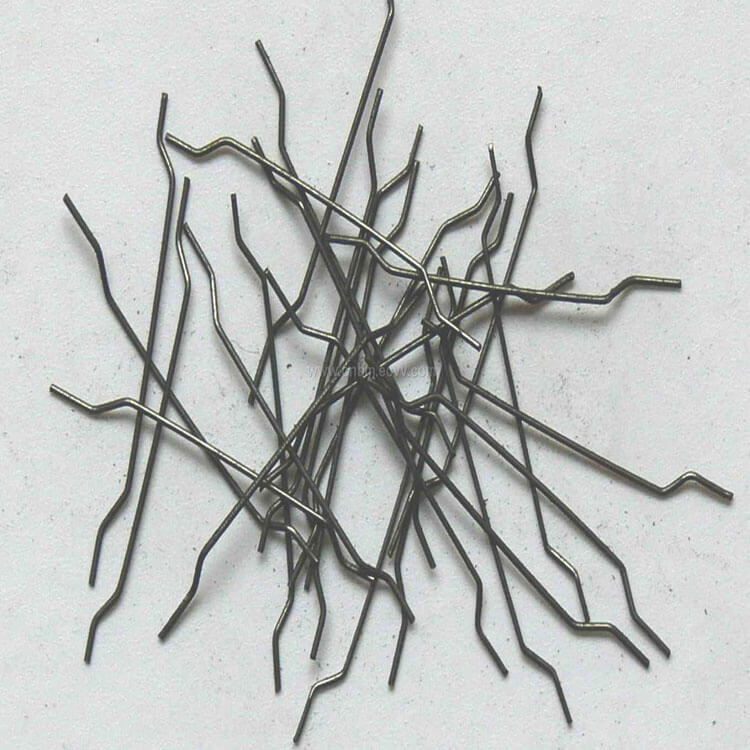

These enhanced types of steel fibers profoundly impact the performance and durability of SFRC. The inclusion of hooked or sinusoidal steel fibers in the concrete matrix creates a synergistic effect, leading to a significant improvement in several key properties.

Firstly, incorporating these specialized fibers enhances the tensile strength of the concrete. The hooks or sinusoidal shapes of the fibers create mechanical interlocking with the surrounding matrix, effectively transferring load and increasing the overall tensile capacity. This reinforcement mechanism helps to control cracking and improve the structural integrity of the SFRC.

Secondly, the hooked or sinusoidal steel fibers enhance the flexural strength and toughness of the concrete. They act as internal reinforcements, distributing stresses and resisting the formation and propagation of cracks. This improved resistance to cracking results in a more durable and resilient concrete structure, capable of withstanding dynamic loads and harsh environmental conditions.

Furthermore, the hooked or sinusoidal fibers improve the impact resistance and energy absorption capacity of SFRC. When subjected to sudden impacts or dynamic loads, such as those experienced in industrial flooring or transportation infrastructure, these fibers effectively dissipate energy and minimize the risk of spalling or surface failure. This characteristic is particularly valuable in high-traffic areas or applications where impact resistance is crucial.

Additionally, the enhanced steel fibers reduce shrinkage and thermal cracking in SFRC. By mitigating the effects of drying shrinkage and temperature variations, these fibers help maintain the concrete’s long-term stability and dimensional integrity. This feature particularly benefits large-scale construction projects or structures exposed to significant temperature fluctuations.

In summary, utilizing hooked or sinusoidal steel fibers in SFRC offers numerous advantages. These fibers improve the tensile strength, flexural strength, toughness, impact resistance, and durability of the concrete. With their ability to mitigate cracking, enhance energy absorption, and reduce shrinkage, these specialized fibers play a vital role in achieving high-performance SFRC for a wide range of applications in the construction industry.

Price of steel fibers:

The price of steel fibers can vary depending on several factors, including the type of fiber, quantity required, market conditions, and suppliers. Generally, steel fibers are priced per kilogram or pound. The cost range for steel fibers can vary from a few dollars per kilogram to several dollars per kilogram, depending on the specific type and quality of the fibers. Obtaining pricing information from reputable suppliers or manufacturers is essential to get accurate and up-to-date pricing for steel fibers.

Growth rate of steel fiber in the industry:

The rate of use and progress of steel fibers in the industry has been steadily increasing over the years. Steel fiber reinforced concrete (SFRC) has gained significant recognition and acceptance as a viable alternative to traditional concrete reinforcement methods.

Regarding the rate of use, there has been a growing adoption of SFRC in various sectors of the construction industry, including infrastructure projects, commercial buildings, industrial facilities, and residential construction. This can be attributed to the numerous benefits offered by SFRC, such as improved durability, enhanced mechanical properties, and increased resistance to cracking and impact.

The progress in the industry has been notable as well. Extensive research and development efforts have been dedicated to optimizing the performance of steel fibers and exploring their applications in different scenarios. This has led to advancements in the design guidelines, manufacturing processes, and testing methods related to SFRC.

Moreover, advancements in fiber technology have resulted in the development of new and improved types of steel fibers. These advancements include variations in fiber shape, aspect ratio, and surface treatments, which further enhance the performance and versatility of SFRC.

Furthermore, industry standards and regulations have been established to ensure proper implementation and quality control of SFRC. Organizations such as the American Concrete Institute (ACI) and various national and international bodies have published guidelines and codes that provide recommendations for designing, constructing, and testing SFRC structures.

Overall, the use rate of steel fibers in the industry is increasing, and significant progress has been made in research, technology, and standardization. This trend indicates the growing recognition and acceptance of SFRC as a reliable and effective construction material, contributing to the advancement of the industry.

Features

- Increased tensile strength

- Increased energy absorption and impact resistance

- Increased resistance to fatigue and rupture strain

- Increased resistance to thermal stress and shrinkage

- Increasing shear, bending and compressive strength

- Saving time, money and materials

- Increased malleability or ductility

Applications

- Reinforcement of concrete floor of factories

- Bridges and highways

- Dams and hydraulic structures

- Railway structures

- Port construction projects and marine structures

- Tunneling and mining

Packaging

- In 10-20 kgs bags

Colour

- Copper

- Gray

technical specifications

|

Equivalent diameter |

0.8-1.2 mm |

| tensile strength |

1050MPa |

| Fiber length |

30-50 mm |

|

appearance |

Bright and clean wire |

| Fiber type |

Sinusoidal and hooked fibers |

- Familiarize yourself with design guidelines and steel fiber reinforced concrete (SFRC) codes.

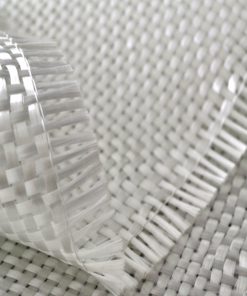

- Understand the properties and characteristics of different steel fibers, including shape, aspect ratio, and surface treatments.

- Conduct thorough material testing to evaluate the performance of steel fibers in SFRC mixtures.

- Collaborate with reputable steel fiber suppliers or manufacturers for guidance and a reliable supply.

- Consider reasonable construction practices for proper placement and finishing techniques of SFRC.

- Engage in continuous learning, attend conferences, and share knowledge with industry professionals to stay updated on advancements in SFRC.

- Understand the project requirements and communicate effectively with the engineer or designer.

- Provide training to your workforce on handling, mixing, and placing SFRC.

- Implement strong quality control measures to monitor SFRC consistency and fiber distribution.

- Select and maintain appropriate equipment and tools for SFRC placement.

- Collaborate and communicate effectively with engineers or designers throughout construction.

- Prioritize safety measures and adhere to relevant safety guidelines.

- Maintain accurate documentation of SFRC mix proportions, fiber amount of usage, and placement techniques.

Mixing Process:

- Add steel fibers to the concrete mix during proper proportioning.

- Follow recommended fiber dosage rate and ensure thorough mixing for uniform distribution.

Placing and Consolidation:

- Use standard concrete placing practices and consolidate with appropriate tools.

- Pay attention to congested areas and maintain uniform flow to prevent segregation.

Finishing and Curing:

- Finish the surface while preserving fiber distribution.

- Apply recommended curing methods for proper hydration and strength development.

Safety Precautions:

- Follow safety measures and use personal protective equipment (PPE) when handling steel fibers.

- Handle fibers carefully to prevent injury.

Documentation and Quality Control:

- Maintain records of fiber dosage, mix proportions, and placement procedures.

- Conduct quality control tests to ensure compliance and document any deviations.

Fiber Selection and Testing:

- Verify fiber compliance and batch consistency.

Fiber Dispersion:

- Ensure uniform distribution during mixing.

Fresh Concrete Testing:

- Assess workability, consistency, and air content.

Strength and Durability Testing:

- Test compressive and flexural strength.

- Consider additional durability tests.

Fiber Content Verification:

- Compare actual and specified fiber content.

Fiber Length Distribution:

- Measure and analyze fiber lengths for consistency.

Document Control:

- Maintain records of fiber properties, mixes, and tests.

Non-Destructive Testing (NDT):

- Use NDT techniques for concrete assessment.

Regular Auditing and Review:

- Evaluate processes and conduct audits for compliance and improvement.

technical documents

Photo Gallery

Technical documentation request

Be the first to review “Steel Fiber”