PRODUCT DESCRIPTION

The Two-Component Polymer Modified Waterproofing Coating (PWC™ code) is an advanced solution designed to seal surfaces effectively. It is specifically engineered to provide exceptional waterproofing and sealing properties, making it an ideal choice for various applications.

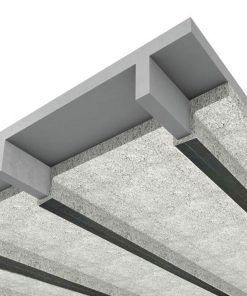

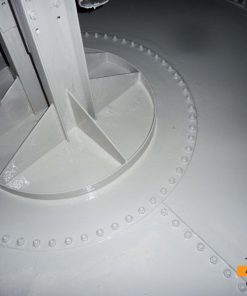

This two-component coating offers unparalleled durability, withstanding hydrostatic and mechanical pressures, with ease. This product delivers reliable and long-lasting results, whether used for insulating concrete structures near water, such as pools and water tanks, or sealing other cement coatings.

One of the key advantages of the Two-Component Polymer Modified Waterproofing Coating is its ability to tackle challenging conditions, particularly in water tank sealing. It effectively addresses problematic issues related to the hydraulic system, ensuring a robust and watertight seal. With this coating, customers can know that the fundamental sealing requirements have been met.

Additionally, the Two-Component Polymer Modified Waterproofing Coating excels in joint coverage. It can seamlessly cover joints up to 5 cm in width, ensuring comprehensive protection and preventing potential water ingress or leakage.

Easy to apply and versatile, this coating is suitable for various surfaces, including concrete, cement coatings, and more. Its two-component formulation provides excellent adhesion, bonding strongly to various substrates and ensuring long-term performance.

Choose the Two-Component Polymer Modified Waterproofing Coating for exceptional waterproofing and sealing capabilities. With its durability, reliable performance, and ease of application, this product is the go-to solution for superior protection against water damage in diverse applications.

Features

- The ability to withstand all kinds of hydrostatic and mechanical forces

- High adhesion with cement and concrete

- Very high flexibility

- Resistant to various chlorine and Chlorosulfate ions

- heat and cold Resistant cycles (-40 to 90 degrees Celsius)

- Resistant to abrasions and mechanical shocks

- Suitable for cooling factories and iron smelting industries

- Applicable on wet surfaces

- Unification of the final color of concrete and insulation coating

- Reducing costs in the long and short term

Applications

Two-component polymer insulation is used in many cases in the construction industry. Its most important application is in concrete and cement sealing. In general, the most important uses of this product are:

- Sealing pools and water tanks

- Sealing terraces

- Sealing of parking lots

- Sealing bridges

- Retaining wall sealing

- Sealing of canals and concrete drains

- Sealing the floor of the bathroom and toilets

- Sealing the walls and facade of the building

- Sealing wet environments such as kitchens or sewage treatment plants

Packaging

- Two component bags

Colour

- grey

technical specifications

|

weight |

2gr/cm2 |

|

color |

grey |

| Maintenance condition |

Store in a dry place away from sunlight |

|

cohesive bond strength |

>1.2 MPa |

| Compressive strength |

>24 MPa |

|

Flexural strength |

>8 MPa |

| penetration strength |

>1.5 MPa |

- Understand the Application Requirements: Familiarize yourself with project requirements and conditions.

- Surface Preparation: Ensure a thorough cleaning and removing contaminants before applying the coating.

- Proper Mixing: Mix the two coating components accurately and completely.

- Application Techniques: Use appropriate methods for uniform coverage and thickness.

- Safety Precautions: Prioritize safety by wearing proper protective equipment and ensuring ventilation.

- Quality Control and Testing: Conduct tests and inspections to ensure the coating meets specifications.

- Maintenance and Inspection: Educate clients on the importance of regular maintenance and cleaning.

- Stay Updated with Industry Standards: Stay informed about industry advancements and best practices.

- Product Familiarization: Understand the coating’s characteristics and application requirements.

- Training and Certification: Obtain proper training and certification for applying the coating.

- Surface Preparation: Thoroughly clean and repair the substrate before application.

- Mixing and Proportions: Follow instructions for accurate and complete mixing of the two components.

- Application Techniques: Use appropriate methods for uniform coverage and thickness.

- Safety Measures: Prioritize worker safety with proper protective equipment and ventilation.

- Curing and Drying Time: Allow the coating to cure and dry completely.

- Quality Assurance: Implement inspections and tests to ensure compliance with standards.

- Clear Documentation: Maintain accurate preparation, mixing, and application details records.

- Ongoing Communication: Keep clients informed and provide guidance on maintenance and care.

To use two-component polymer insulation, there is no need to mix it with water, and the existing powder and the desired resin are mixed together. One of the advantages of two-component polymer insulation is its quick and easy composition. The surface on which the two-component polymer insulation is to be applied must be free of any dust or oil particles and any sticky particles. Metal surfaces must also be clean before use, and any rust or oil stains must be removed from them. All surfaces should be as smooth as possible before use. Porous and water-absorbing surfaces must also be completely saturated before use; So that there is no excess water on their surface. The specialists of Afzir retrofitting company recommend for better sealing, the implementation of waterproofing in at least 2 layers as follows.

- Levels of terraces, toilets: 1.0 kg/m² in each layer.

- On the surfaces where the water is above 1 meter: 1.5kg/m² in each layer

- On surfaces where water is at least 1 meter above them: 2.0 kg/m² per layer

- For protective layer: 2.0kg/m² per layer (protective layer is recommended in places that are heavily exposed to water).

- Pre-Application Inspection: Inspect the substrate for defects and ensure it meets requirements.

- Adhesion Test: Conduct tests to evaluate coating adhesion strength.

- Mixing Proportions: Verify the correct mixing proportions of the coating components.

- Application Thickness: Measure and monitor coating thickness to maintain uniformity.

- Visual Inspection: Regularly inspect for surface imperfections during application.

- Curing and Drying Time: Monitor and record the coating’s curing and drying time.

- Post-Application Inspection: Conduct a final inspection to check for defects and ensure adherence to quality standards.

- Documentation: Maintain accurate records of inspections, measurements, and corrective actions taken.

technical documents

Photo Gallery

Technical documentation request

Be the first to review “Two Component Polymer Modified Waterproofing Coating”