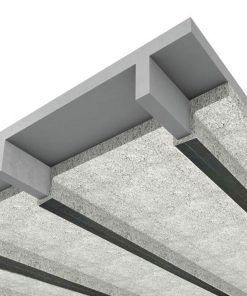

PRODUCT DESCRIPTION

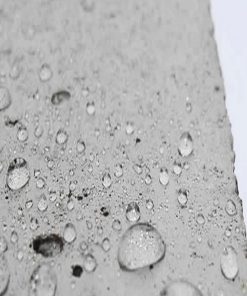

The Water Repellent Nano Coating for Fire Brick (code WNFB™) is an advanced nano waterproofing solution designed to protect firebricks. Utilizing cutting-edge nanotechnology, the particles composing this nano-brick coating have diameters ranging from 1 to 100 nanometers. When applied, these millions of microscopic or nanometer-sized particles uniformly spread across the surface, deeply penetrating the refractory brick. This infiltration effectively blocks all openings and pathways through which harmful substances could enter the bricks. Additionally, it imparts a waterproof feature to the brick facade, safeguarding it against water penetration, dust, and other destructive elements. By extending the bricks’ lifespan, these nanomaterials’ application enhances their durability. Furthermore, the self-cleaning nano-hydrophobic coating bestows a dust-proof property, ensuring a clean appearance.

One of the notable advantages of WNFB™ is its environmental compatibility. This nano brick coating is simple, requiring only essential tools such as a spray, brush, or roller.

The Price of Nano Materials for Building Facades

The price of the nano-brick coating varies and is typically presented per liter unit in the market. Several factors influence the pricing, including the product brand, the currency of the manufacturing country, market fluctuations, and the composition of the nano brick facade waterproofing. Due to these variables, providing a single price for this nano brick waterproofing is impossible. We recommend reaching out to our experts at Afzir Retrofitting for advice and to inquire about the exact pricing of various nano insulation products for building facades, such as nano brick coatings, nano paint for building facades, and nano waterproofing products.

Features

- Suitable for all types of refractory brick facades

- Based on nano technology

- Contains very fine nano particles with a diameter of 1 to 100 nm

- Water repellency

- Water-based

- Keeping the surfaces clean due to reducing the penetration of pollution

- Easy to apply

- Fast setting

- Resistant to environmental conditions

- Maintaining the breathability of the brick

- Not changing the appearance of the brick

Applications

- Suitable for all types of refractory brick facades

- Outdoor Structures and Walls

- Historical and Cultural Buildings

- Commercial and Industrial Structures

- Residential Buildings

- Fireplaces and Chimneys

Packaging

- –

Colour

- colorless

technical specifications

|

Physical basis |

colorless |

|

Shelf time |

12 months |

| Maintenance condition |

5-40℃ |

|

chemical basis |

Modified Alkaline Silane |

|

density |

1.4 Kg/L |

| PH |

13-14 |

- Understand the Product: Familiarize yourself with the nano coating’s composition, application techniques, and performance characteristics.

- Surface Preparation: Ensure a thorough cleaning and proper drying the brick surface before application.

- Application Techniques: Follow recommended techniques for even and uniform coating application.

- Dilution and Mixing: Dilute the coating accurately and mix thoroughly according to manufacturer instructions.

- Safety Measures: Prioritize safety by wearing appropriate PPE during application.

- Compatibility Testing: Test a small area for compatibility and desired results before full-scale application.

- Collaborate with Suppliers and Experts: Seek guidance and expertise from suppliers and professionals in the field.

- Regular Maintenance and Inspection: Schedule routine maintenance and inspections to ensure continued performance.

- Stay Updated on Technological Advancements: Stay informed about industry developments and advancements in nano-coating technology.

- Documentation and Record Keeping: Maintain thorough application process documentation for future reference and quality control.

- Familiarize Yourself with the Product: Understand the nano coating’s specifications and performance characteristics.

- Surface Preparation: Clean and prepare brick surfaces before applying the coating.

- Follow Application Guidelines: Adhere to the manufacturer’s instructions for consistent and uniform coating application.

- Dilution and Mixing: Dilute the coating accurately and thoroughly for optimal performance.

- Safety Measures: Prioritize worker safety by providing appropriate PPE and following safety protocols.

- Quality Control and Testing: Perform regular inspections to ensure proper adhesion and coverage.

- Collaborate with Suppliers and Experts: Seek guidance from suppliers and experts for product recommendations and troubleshooting.

- Project-Specific Considerations: Tailor the application approach to project requirements and environmental factors.

- Clear Documentation: Maintain records of surface preparation, coating measurements, and application techniques.

- Ongoing Maintenance and Support: Educate clients on maintenance routines and offer continued support for long-term effectiveness.

Preparation:

- Before applying the product, thoroughly clean the surface to remove contaminants like oil, dust, and paint. Ensure the surface is completely dry.

Mixing:

- Mix WNFB™ coating with 30 parts water.

Application Steps:

- Apply WNFB™ coating to the desired surface using a spray or brush.

- Allow the coating to dry.

- The surface is ready for use.

Limitations:

- Do not reapply nanomaterials to the surface after applying and drying them.

- Ensure complete coverage and even distribution of the materials on the surface.

Product Storage:

- Store the product in dry places.

- Keep it covered and dry in the environment.

- Maintain a storage temperature between 5 to 40 degrees Celsius.

- Avoid freezing the product.

- Seal the container tightly after each use.

- The shelf life of the product is a maximum of 1 year.

- Define Quality Standards: Establish the desired quality specifications for the nano-coating.

- Sampling and Testing: Develop a sampling plan and perform regular tests to ensure compliance with quality standards.

- Calibration of Testing Equipment: Regularly calibrate testing equipment to maintain accurate and reliable results.

- Document Procedures and Results: Maintain detailed records of quality control procedures and test outcomes.

- Continuous Monitoring: Implement a system to monitor the coating application process and ensure consistency.

- Training and Competence: Train personnel in quality control and assess their competence.

- Supplier Quality Assurance: Collaborate closely with suppliers to maintain consistency in raw material quality.

- Feedback and Improvement: Gather feedback from customers and contractors to identify areas for improvement.

- External Quality Assurance: Consider third-party testing and certification to validate product quality.

- Continuous Improvement: Foster a culture of continuous improvement and implement corrective actions based on data analysis

technical documents

Photo Gallery

Technical documentation request

Be the first to review “Water Repellent Nano Coating for Fire Brick”