PRODUCT DESCRIPTION

WHEN MIXED WITH WATER, the ERG™CR chemically resistant epoxy grout is formulated to transform into a non-shrinking mortar, ensuring quick and efficient curing. This versatile epoxy grout is ideal for various applications, including bedding, grouting, rebar planting, hole filling, and base plate height adjustment. This grout offers easy application in confined spaces with limited thickness by utilizing special epoxy resins and well-graded aggregates. In the following sections, we will explore the distinctions between epoxy and cement grout, the application methods, properties, technical characteristics, specifications, and various uses of epoxy grout mixtures.

Differences between epoxy grout and cement-based grout:

Unlike cement grout, which consists of a mixture of cement powder, epoxy grout comprises epoxy resin, hardener, and silica aggregates.

The following characteristics set epoxy grout apart from cement grout:

-

Enhanced load tolerance:

Epoxy grout exhibits superior static and dynamic load tolerance compared to cement-based grout.

-

Exceptional bonding:

Properly mixed and applied epoxy grout forms a bond of over 90 percent with steel plates and baseplates.

-

Improved connection and adhesion:

Epoxy grout establishes a stronger bond and adhesion between foundation concrete, column plates, and baseplates.

-

Increased strength:

Epoxy grout demonstrates higher tensile and flexural strength than cement grout, with chemical-resistant epoxy grout reaching 120 MPa compressive strength and 17 MPa tensile strength.

-

Rapid hardening:

Epoxy grout hardens at a faster rate than conventional grout, significantly reducing application time.

-

Optimal compressive strength:

Within 24 to 48 hours of grouting, epoxy grout achieves optimal compressive strength for load-bearing purposes.

-

Superior chemical resistance:

Chemical-resistant and anti-acid epoxy grout surpasses concrete and cement-based grout in terms of chemical resistance, making it ideal for challenging chemical environments.

-

Enhanced adhesive strength:

Epoxy grouts offer significantly higher adhesive strength than cement grouts, enabling them to withstand shear forces and transfer lateral loads caused by wind, earthquakes, and other factors from the plate to the foundation.

-

Impact resistance:

Cement-based grout is not designed to withstand impact loads and vibrations from heavy machinery. In contrast, epoxy grout maintains its integrity, preventing cracks and potential hazards when subjected to such stresses.

Choose ERG™CR chemically resistant epoxy grout for reliable and long-lasting performance in demanding grouting applications.

Regarding durability and longevity, the ERG™CR chemically resistant epoxy grout surpasses cement-based alternatives. Its ability to withstand impact loads and vibrations from heavy machinery ensures a secure and stable foundation, minimizing the risk of damage or accidents. In contrast, cement grouts are prone to cracking and deterioration under similar conditions, posing significant safety concerns.

The ERG™CR epoxy grout also offers excellent resistance to various chemicals and acids, outperforming traditional concrete and cement grouts. This makes it the ideal choice for industries such as manufacturing, chemical processing, and food production, where exposure to corrosive substances is constantly challenging. Its exceptional chemical resistance protects the grout’s structural integrity and safeguards the surrounding environment from potential leaks or contamination.

Furthermore, the ERG™CR epoxy grout provides ease of use and application. Its non-shrinking properties ensure a precise fit during the grouting process, reducing the risk of gaps or voids that can compromise structural stability. The quick curing time allows for faster project completion, minimizing downtime and maximizing productivity. Whether it’s bedding applications, grouting tasks, rebar planting, or hole filling, the ERG™CR epoxy grout delivers reliable results efficiently and effectively.

In summary, the ERG™CR chemically resistant epoxy grout offers a superior alternative to cement-based grouts. Its unmatched load tolerance, exceptional bonding strength, rapid hardening, and enhanced chemical resistance make it the preferred choice for demanding environments. With the ERG™CR epoxy grout, you can ensure long-lasting durability, safety, and performance for your grouting needs.

Features

- High resistance to chemicals and acids

- Excellent adhesion to concrete, steel, and most building materials

- Achieves excellent initial and final mechanical strength

- Demonstrates outstanding chemical stability

- Provides exceptional stability under static and dynamic loads

- Easy to mix and use

- Low odor and safe for users

- Maintains good consistency even in limited spaces and thin layers

- Non-shrinkage during the hardening process

- Prevents corrosion of reinforcements

- No need for primer during the applicat

Applications

- Structural filling of cavities and concrete holes

- Grouting in limited spaces under the columns, equipment and industrial machines that have fixed and moving loads.

- Installation of transmission cables and crane base

- Installing screws and rebar in concrete

Packaging

- Three components bucket in weights of 25 and 50 kg

Colour

- Grey slurry (after mixing)

technical specifications

|

Mixing ratio |

A : B : C = 2 : 1 : 2 |

| pot life |

20 min |

|

density |

2.23 Kg/L |

|

compressive strength |

119MPa |

|

Tensile strength |

16.8MPa |

| flexural strength |

34.5MPa |

- Familiarize yourself with the product: Understand its properties and specifications.

- Proper surface preparation: Ensure clean and dry surfaces are free from contaminants.

- Accurate mixing: Follow recommended ratios and procedures for a homogeneous mixture.

- Appropriate application techniques: Choose suitable methods for proper coverage and consolidation.

- Consider expansion joints: Incorporate joint locations into the design to accommodate movements.

- Adhere to safety precautions: Wear proper PPE and follow the manufacturer’s safety guidelines.

- Conduct quality control tests: Verify grout properties to meet project specifications.

- Monitor curing conditions: Maintain suitable temperature and humidity for proper hardening.

- Regular maintenance and inspection: Assess grout condition and implement maintenance practices.

- Seek professional advice if needed: Consult experts or the manufacturer for guidance in challenging situations.

- Minimum application thickness: Ensure a minimum execution thickness of 20 mm.

- Maximum application thickness: Avoid exceeding a maximum execution thickness of 100 mm.

- Suitable temperature for grouting: Do not apply the grout at temperatures lower than 5°C.

- Avoid dilution with solvent: Refrain from diluting the grout with solvent as it can reduce its compressive and tensile strength.

- Consider substrate concrete age: The substrate concrete should be between 21 and 28 days, depending on its curing and drying conditions.

Surface Preparation:

- Ensure the concrete surface is clean, sound, and as free as possible from water and grease. Remove any damaged concrete.

Cleaning the Surface: - Approved chemicals can be used to clean the concrete surface effectively.

Mixing:

- Open the bucket and remove the sheet. Pour the hardener (part B) into the resin bucket (part A) and stir the mixture using a spatula or hand mixer until it achieves a uniform color.

- Low-speed and high-speed mixers can be used, but avoid using air bubbles in the mixture. Over-mixing can compromise grout quality.

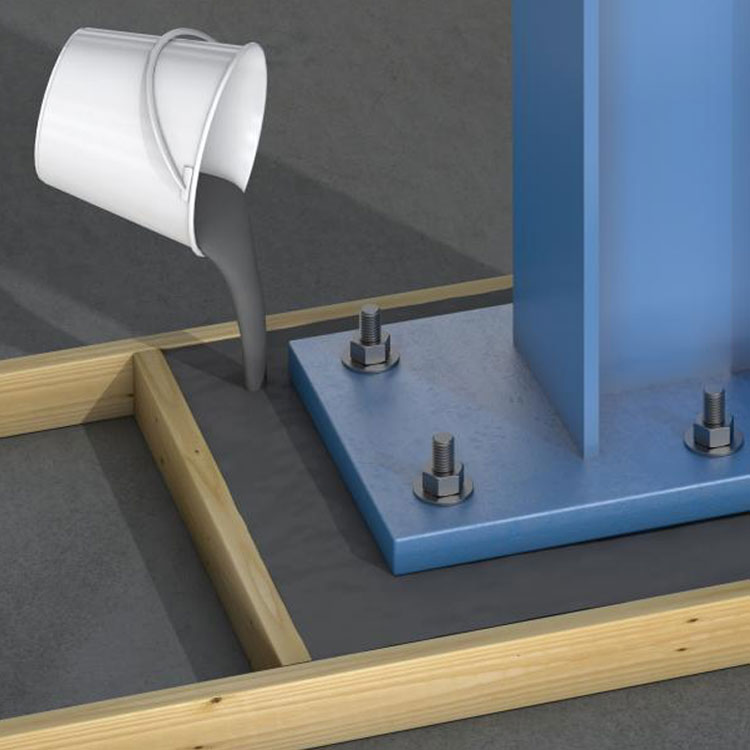

Pouring and Air Removal:

- Pour the mixed grout continuously from one side to eliminate air entrapment.

- Maintaining a continuous flow of grout is crucial.

- Sufficient grout should be prepared before starting the grouting process.

Pot Life and Timing: - Pay attention to the pot life of the product while grouting.

Curing Process:

- Epoxy grout requires curing to retain moisture. Use curing compounds or cover the grout with a wet sack after pouring. The duration of the curing process depends on weather conditions and typically lasts up to three days. Afterward, the grout will achieve favorable compressive strength for loading.

- Avoid inhaling epoxy grout fumes.

- When the concentration of grout vapor is high, it is recommended to use local ventilation devices and masks to minimize the inhalation of harmful gases.

- Keep epoxy away from fire as burning epoxy releases dangerous fumes.

- Take precautions to avoid skin or eye contact. In case of contact, wash the affected skin with soap and water. If the eyes are affected, rinse with water for 15 minutes.

- Before using epoxy grout, carefully read and understand all precautions, specifications, and properties provided by the product manufacturer.

technical documents

Photo Gallery

Technical documentation request

Be the first to review “Chemical Resistance Epoxy Grout”