PRODUCT DESCRIPTION

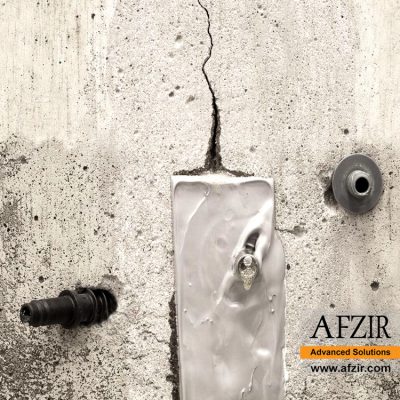

The epoxy injection adhesive is a two-component adhesive with a standard viscosity. It is commonly employed for repairing cracks in concrete structures. Specifically formulated to be used with automatic metering, mixing, dispensing, and injection equipment, this adhesive ensures convenient application. The recommended volumetric ratio for mixing the adhesive components is 4:1. Prior to application, thoroughly cleaning the concrete surface is crucial, eliminating any substances that may hinder bonding.

This product is formulated using ultra-thin epoxy resins. It is specifically designed for injection into capillaries and micro-cracks wider than 100 microns found in various structural elements like columns, beams, foundations, walls, and floor sections. Its injection results in permanent blockage of cracks while providing structural connectivity between concrete sections, effectively creating a unified structure. Compatibility is a noteworthy characteristic of this product, further enhancing its efficacy.

Properties of epoxy injection adhesive

This epoxy injection adhesive offers exceptional durability and long-lasting performance. Once cured, it forms a strong and resilient bond that effectively withstands the stresses and strains experienced by concrete structures over time. This not only ensures the structural integrity of the repaired areas but also helps prevent further damage and the need for additional repairs in the future.

In addition to its repair properties, this epoxy injection adhesive contributes to the aesthetic appeal of the repaired concrete surfaces. It possesses excellent leveling properties, allowing for a smooth and even finish that seamlessly blends with the surrounding concrete. This makes it an ideal choice for applications where functionality and visual appeal are essential.

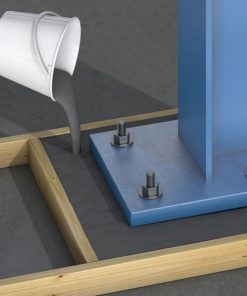

Moreover, the versatility of this product extends beyond crack repair. It can also be utilized to create structural connections and reinforce weakened areas within concrete elements. Injecting the adhesive into designated areas effectively strengthens the overall structure and enhances its load-bearing capacity. This adaptability makes it a valuable asset in various construction and renovation projects.

When using this epoxy injection adhesive, following the manufacturer’s instructions for proper handling, mixing, and application is essential. Adhering to the recommended procedures ensures optimal results and maximizes the adhesive’s performance. Additionally, it is essential to note that this product is intended for professional use and should be handled carefully, following all necessary safety precautions.

Overall, the epoxy injection adhesive is a reliable and efficient solution for repairing cracks, reinforcing concrete structures, and improving their overall durability. Its compatibility, ease of use, and ability to provide long-term structural benefits make it an essential tool for construction professionals seeking effective concrete repair solutions.

The rate of epoxy injection adhesive growth

The growth rate in the industry can be attributed to several factors. Firstly, the increased awareness about the importance of maintaining and preserving existing infrastructure has led to a higher demand for concrete repair and restoration. As a result, industries such as construction, civil engineering, and infrastructure development have embraced epoxy injection adhesives as a reliable solution for addressing concrete cracks and structural deficiencies.

Additionally, the advancements in epoxy technology have played a significant role in driving the industry’s growth. Manufacturers have developed high-quality formulations that offer improved bonding strength, enhanced durability, and faster curing times. These advancements have not only made the adhesives more effective but also increased their overall reliability, leading to greater customer satisfaction and market demand.

Purchase price of epoxy injection adhesive

When it comes to the price of epoxy injection adhesives, it can vary depending on factors such as the brand, quality, and quantity required.

Generally, epoxy injection adhesives are considered a cost-effective solution due to their long-term benefits and durability. While they may have a higher upfront cost compared to traditional repair methods, their ability to provide long-lasting repairs and prevent future damage can result in significant cost savings over time.

It’s important to note that pricing can also vary based on regional factors, market competition, and specific project requirements. It’s advisable to consult with suppliers or manufacturers to get accurate pricing information based on your specific needs.

The growth rate in the epoxy injection adhesive industry has been driven by increasing awareness about infrastructure maintenance, the versatility of adhesives, and advancements in epoxy technology. While pricing can vary, epoxy injection adhesives are generally considered a cost-effective solution due to their long-lasting performance and ability to prevent further damage, making them a valuable investment for construction and repair projects.

Key Features

- Forms bonds with dry and wet surfaces.

- Excellent adhesion to concrete and most building materials as well as high tear strength.

- Gain excellent initial and final resistances.

- Moisture tolerance before, after and during hardening.

- Excellent chemical stability.

- Stability against impact and vibration.

- Good wetting ability and as a result full penetration into the cracks.

- Low concentration and high penetration power.

- Easy to use.

- No shrinkage during drying.

- It does not damage the armatures.

- Can be used in dry and wet conditions.

Applications

- EIR™, injection epoxy resin is used for injection in cracks, joints and cavities in concrete, stone and brick structures.

Packaging

- Two components (liquid) buckets

Colour

- Light yellow liquid

technical specifications

|

Appearance |

Light yellow liquid part A: colorless liquid part B : amber liquid |

|

Mixing ratio |

A : B = 4 : 1 |

| Operating temperature |

-35 ℃ – 65℃ |

|

Final setting time |

14 days (25 ℃) |

| Gel time |

40 minutes (25℃) |

| Density |

1.5 g/cm3 |

|

Adhesion stability (concrete peels off) |

2.5 MPa |

| Compressive strength (after 7 days) |

55 MPa |

| Flexural strength (after 7 days) |

35 MPa |

- Crack Width: Consider the suitable crack width (0.1-9 mm) for effective injection and bonding.

- Temperature Control: Maintain a minimum temperature of 5 °C and a maximum temperature of 40 °C during injection to preserve adhesive properties.

- Avoid Solvent Weakening: Do not thin the adhesive with solvents, as it weakens resistance.

- Substrate Concrete Age: Apply the resin between 21 and 28 days after concrete placement, considering curing and drying conditions.

- Follow Manufacturer’s Instructions: Adhere to product guidelines for mixing ratios, application techniques, curing times, and safety precautions.

- Cleanliness and Preparation: Thoroughly clean and dry the crack or surface to ensure proper adhesion.

- Equipment and Calibration: Use clean and calibrated injection equipment for accurate application.

- Curing Conditions: Provide appropriate temperature and moisture conditions for optimal curing.

- Safety Precautions: Adhere to safety guidelines and use appropriate personal protective equipment.

- Continuous Learning: Stay updated with industry advancements to enhance expertise in concrete crack repair.

- Surface Preparation: Ensure thorough cleaning and preparation of the surface before applying the epoxy injection adhesive.

- Follow Manufacturer’s Guidelines: Adhere to the instructions and guidelines provided by the adhesive manufacturer for proper mixing ratios, application techniques, and curing times.

- Quality Equipment: Invest in reliable and calibrated equipment suitable for epoxy injection processes.

- Safety Precautions: Prioritize worker safety by providing appropriate personal protective equipment (PPE) and following safety regulations.

- Temperature and Humidity Control: Maintain recommended temperature and humidity levels during application and curing.

- Monitor Injection Pressure: Pay attention to injection pressure to ensure proper flow and penetration of the adhesive into cracks.

- Allow Sufficient Curing Time: Give the epoxy adhesive enough time to fully cure before subjecting the repaired area to heavy loads or traffic.

- Regular Inspections: Conduct routine inspections to identify any damage or new cracks and address them promptly.

- Proper Waste Disposal: Dispose of adhesive leftovers and waste materials following local regulations and environmentally friendly practices.

- Continuous Training and Education: Stay updated with industry advancements and participate in training programs to enhance skills and knowledge in epoxy injection applications.

- Suitable crack width for injection: Ensure that the crack width falls within the range of 0.1-9 mm for the effective application of EIR ™ epoxy injection adhesive. Cracks within this range are suitable for optimal bonding and repair.

- Minimum temperature during injection: The minimum temperature required during the injection process is 5 °C. It is important to maintain this temperature to ensure proper adhesive viscosity and flow characteristics for successful application.

- Maximum temperature during injection: The maximum temperature allowed during the injection process is 40 °C. Exceeding this temperature may affect the adhesive’s performance and compromise the bond strength, so it is crucial to adhere to this limit.

- Avoid dilution with solvent: It is important to note that EIR ™ epoxy injection adhesive should not be diluted with solvents. Diluting the adhesive with solvents can diminish its resistance properties and compromise the overall effectiveness of the repair. Therefore, using the adhesive in its original form is recommended without dilution.

- Age of the substrate concrete: The age of the substrate concrete plays a vital role in the application of the resin. Before applying the EIR ™ epoxy injection adhesive, ensure that the substrate concrete has aged between 21 and 28 days. The exact duration may vary depending on curing and drying conditions. Following curing guidelines and allowing the concrete to reach the appropriate age is essential before proceeding with the application.

Note: It is important to refer to the specific product’s technical data sheet and the manufacturer’s instructions for detailed application guidelines, safety precautions, and additional recommendations. Adhering to the instructions will ensure optimal performance and long-lasting results when using EIR ™ epoxy injection adhesive.

- Establish Quality Control Procedures: Develop a comprehensive plan outlining the steps for quality control.

- Training and Certification: Ensure personnel receive proper training and certification.

- Standardized Testing Methods: Use standardized tests to evaluate adhesive properties.

- Material Verification: Verify the quality and specifications of the epoxy adhesive.

- Equipment Calibration: Regularly calibrate injection equipment for accuracy.

- Surface Preparation Inspection: Thoroughly inspect the prepared surface before application.

- Mixing and Application Process Control: Implement strict controls for proper mixing and application.

- Cure Monitoring: Monitor the curing process and adhere to recommended times.

- Visual and Non-Destructive Testing: Perform inspections and non-destructive tests.

- Documentation and Reporting: Maintain detailed records of quality control activities.

- Continuous Improvement: Regularly review procedures and incorporate best practices for improvement.

technical documents

Photo Gallery

Technical documentation request

Frequently Asked Questions

Why is injected epoxy resin used?

After injection, this product causes permanent blockage of cracks and pores against the penetration of invading liquids and gases. It also connects concrete sections structurally and has the ability to integrate structural parts.

How many components is an injection epoxy resin made of?

Injectable epoxy resin is made of two hardening and curing agents.

Are colored injection epoxy resin components available?

Component A is a clear liquid, component B is an amber liquid, and finally is a pale yellow liquid.

What is the mixing ratio of injection epoxy resin components?

The components are combined in a ratio of 4 to 1. In fact, for every 4 components A, 1 component B must be mixed.

What should be the appropriate width for crack injection?

Suitable crack width for injection is 0.1 to 9 mm.

What is the age of concrete bed to apply injection epoxy resin?

The age of the substrate concrete for applying the resin should be between 21 and 28 days, depending on the curing and drying conditions.

What are the properties of injection epoxy resin?

They have desirable properties such as excellent adhesion, chemical resistance to acids, low drop, low curing time and moisture resistance.

What is the important and unique feature of epoxy injection resins?

An important feature of epoxy injection resins is high compatibility with moisture.

What is the price of injection epoxy resin?

Due to the nature of epoxy resin, which is a polymer product and is mass-produced, consumers can buy the product in the market with a wide range of prices. For information on the price of our company's products, you can contact the Afzir company experts.

Be the first to review “Epoxy Injection Resin”