PRODUCT DESCRIPTION

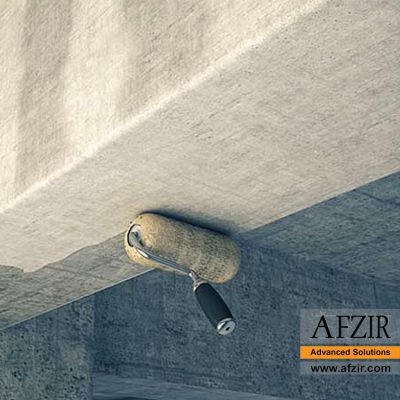

The WEP™240 Primer is a user-friendly 4:1 volumetric mix that cures quickly and has a low odor. Epoxy primers are widely chosen for their strong adhesion, excellent mechanical properties, and durable chemical resistance in wet and high-humidity environments.

The corrosion resistance of an epoxy primer is influenced by its thickness, and WEP™240 excels in penetrating fine cracks in building materials. Moreover, its diluted formulation creates a strong bond and achieves a smooth surface finish by effectively penetrating the capillary surface of the concrete.

Epoxy primers provide superior adhesion to metals and serve as an ideal base for additional undercoat and topcoat products. They are commonly employed to coat metal cans and containers, particularly those used for acidic food preservation, such as tomatoes.

FRP Primer exhibits excellent bonding capabilities with minimal surface preparation and even in the presence of moisture. However, removing contaminants like standing water, rust, and dirt is advisable before applying FRP Primer. Sanding or scuffing the substrate can enhance its bonding performance. FRP Primer may not adhere well to untreated plastics or surfaces contaminated with petroleum products.

Factors Affecting Price:

Several factors can influence the price of WEP™240 Primer and other epoxy primers. These factors include:

Product Quality:

High-quality epoxy primers with superior adhesion, durability, and chemical resistance typically command a higher price due to their formulation’s advanced technology and ingredients.

Quantity:

The quantity of primer being purchased can impact the price. Bulk orders or larger volumes often lead to volume discounts, resulting in a lower per-unit cost.

Packaging:

The type and size of packaging can affect the price. Specialized packaging options, such as convenient dispensing systems or individual cartridges, may come at a higher cost than standard packaging.

Brand Reputation:

Well-established brands known for their reliability and performance may have a higher price point compared to lesser-known or generic alternatives.

Market Demand:

Supply and demand dynamics in the market can influence pricing. If there is high demand for epoxy primers, prices may increase. Conversely, lower demand can lead to more competitive pricing.

Distribution and Logistics:

Factors such as transportation costs, storage requirements, and distribution channels can impact the product’s final price. It is essential to consider these factors when evaluating the price of WEP™240 Primer or any epoxy primer, as they can vary depending on the specific circumstances and market conditions.

Key Features

- Superior adhesion to concrete and various building materials

- Impressive initial and final resistances

- Outstanding chemical stability

- Resistant to impact and vibration

- Exceptional penetration into dry and wet substrates

- Up to 20% reduction in resin consumption during retrofitting operations

- Low concentration with high penetration power

- User-friendly and easy to apply

- No shrinkage during the drying process

- Extended pot life for convenient use

Applications

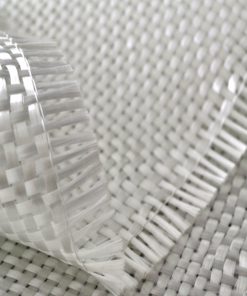

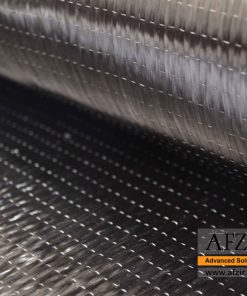

- Priming dense and hard concrete surfaces in both dry and wet conditions before FRP application

- Use as a primer for all types of repair mortars

- Enhancement of mechanical properties in hardened concrete by penetrating pores and forming durable polymers

- Obstruction of micro-cracks in concrete

- Stabilization of porous structures

- Coverage of dry and wet concrete surfaces

- Primer for epoxy industrial flooring applications

- Suitable primer for paint and flooring in hygienic environments

- Recommended primer for fire protection purposes

Packaging

- In a package of 10 kg (total components)

Colour

- Light yellow (after mixing)

technical specifications

| appearance |

Light yellow (after mixing) Part A: light yellow liquid Part B: clear liquid |

| Mixing ratio |

A:B= 4:1 |

| density |

1.30 Kg/L |

| number of layer |

One layer for compact surfaces and two layers for porous surfaces |

| pull off Adhesion testing |

2.5 MPa |

| curing temperature |

Between -35°C until 65°C |

| Initial setting time (at 25°C) |

24 hour |

| Final setting time(at 25°C) |

14 days |

| Pot life (at 25°C) |

90 min |

- Shake each section well before use.

- Add Part B to Part A.

- Mix the two components for two to three minutes using a slow drill equipped with a suitable mixer to achieve a uniform mixture.

- For smaller volumes, combine one volume of Section B with four volumes of Section A in a clean mixing bowl.

- Mix the combined components thoroughly.

- Always ensure the mixed resin

technical documents

Photo Gallery

Technical documentation request

Frequently Asked Questions

What is Epoxy Primer?

Frp epoxy primer is a two-component compound with low viscosity and concentration that is used to prepare the substrate before any repair and hardening operations. By applying epoxy primer to the desired substrate, the primer penetrates deep into small cracks or pores in the substrate and causes them to become blocked. This action increases and improves the mechanical properties of the substrate. In addition, the application of epoxy primers can help to better bond and reduce the consumption of resin in the installation of FRP products on concrete surfaces for reinforcement.

What is the property of epoxy primer?

FRP epoxy primer has good adhesion to most substrates such as concrete. In addition, its low viscosity, low concentration and high permeability make it easy to saturate the substrate and penetrate deep into the substrate. FRP epoxy primer is highly resistant to moisture and corrosion. These types of primers work quickly.

What are the uses of epoxy primer?

The most common application of FRP epoxy primer is to prepare the substrates before performing the retrofitting operation using FRP products. In addition, FRP epoxy primer, in order to block fine concrete cracks and improve the mechanical properties of hardened concrete, bedding for epoxy industrial flooring, primer for paint and flooring in sanitary environments, primer for fireproof coatings, stabilization Porous structures, etc. are used.

What is the penetration power of epoxy primer on surfaces?

FRP epoxy primer has high permeability. In such a way that it can block penetration and pores or small pores that cause moisture, destructive chemicals, etc. to the depth of the bed, such as concrete.

What is the gel time or working time of epoxy primer?

The working time of FRP epoxy primer at 25°C is about 90 minutes.

At what temperature can FRP epoxy primer be used?

The best temperature for maximum use of FRP epoxy primer is -35 to +65 degrees Celsius.

How to mix the components of FRP epoxy primer?

Shake each section well first. Part B is added to Part A and mixed for two to three minutes using a slow drill equipped with a suitable mixer, to obtain a uniform mixture. To make smaller volumes, pour one volume of Section B with 4 volumes of Section A in a clean container and mix well. Try to mix only the required amount of FRP epoxy primer, all of which can be consumed within the performance time or gel time.

What color is the epoxy primer?

FRP epoxy primer is made of two components A and B. Component A is a light yellow liquid and component B is a clear liquid. The combination of these two components ultimately provides a light yellow color.

What is the price of epoxy primer?

FRP epoxy primer is sold in the market in kilograms. Due to market fluctuations, the price of FRP epoxy primer also varies. Therefore, for detailed inquiries about the price of FRP epoxy primer, you can contact our experts in Afzir.

How to make FRP epoxy primer?

To prepare FRP epoxy primer, you can proceed through Afzir collection, which is one of the most active companies in the field of product supply, execution, design and consulting in the field of structural reinforcement.

Be the first to review “FRP Primer”