PRODUCT DESCRIPTION

GEP™ is a fast-setting, non-shrinking epoxy putty and mortar designed for general-purpose repairs. It establishes a strong bond with building materials and boasts impressive mechanical properties and chemical stability. Due to its outstanding qualities, it serves as an ideal product for a wide range of applications.

Whether you need to patch up cracks, fill gaps, or restore damaged surfaces, GEP™ excels in delivering reliable and durable results. Its quick-setting nature ensures efficient repairs, saving you valuable time and minimizing disruptions. The non-shrinking formula guarantees a tight and seamless finish, eliminating the risk of cracks reappearing over time. With its exceptional bond strength, GEP™ creates a long-lasting connection between different materials, including concrete, wood, and metal. Its impressive chemical stability also ensures resistance to various environmental factors, such as moisture, chemicals, and temperature fluctuations. This versatility and reliability make GEP™ a trusted choice for professionals and DIY enthusiasts. Whether you’re working on small household repairs or larger-scale projects, GEP™ provides the peace of mind that your repairs will withstand the test of time.

Key Features

- Excellent adhesion to concrete and other building materials

- Achieves high initial and final resistance

- Demonstrates excellent chemical stability

- Provides stability against shock and vibration

- Colored components for easy mixing

- User-friendly with minimal odor

- Non-dripping and non-flowing

- Non-shrinking during curing

- Does not cause steel corrosion

- Suitable for horizontal and vertical surfaces

- Capable of repairing concrete

Applications

- Leveling and bedding of bridge decks or metal bumpers

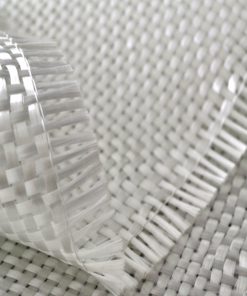

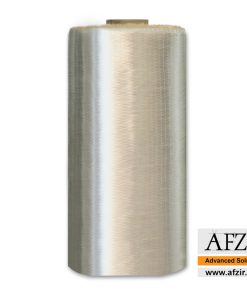

- Leveling and bedding of surfaces for installation of FRP fibers and FRP laminate in retrofitting projects

- Repairing damaged concrete surfaces in horizontal, vertical, or overhead positions

- Filling screw holes and bolts

- Ceramic tile substructure

- Installation of surface packer for injection in concrete cracks and filling resulting holes

- Bonding metal plates, tape, and composite sheets to concrete and other building materials

- Leveling the bottom layer of roofs and beams

Packaging

- in 12 kg packaging (total components)

Colour

- Gray paste (after mixing)

technical specifications

|

Appearance |

gray paste (after mixing) Part A: hard gray paste Part B: Transparent |

|

Mixing ratio |

A: B = 5: 1 |

|

Specific weight |

1.75Kg/L |

|

Compressive strength (after 7 days) |

65MPa |

|

flexural strength (after 7 days) |

20MPa |

| Adhesion stability (concrete peels off) |

2.5MPa |

| Operating temperature |

-35℃-65℃ |

|

Final setting time (at 25°C) |

7 days |

| Gel time |

60 minutes |

Summary of suggestions and tips for engineers working with FRP epoxy putty:

- Familiarize yourself with the specific FRP epoxy putty properties and application requirements.

- Ensure proper surface preparation before applying the epoxy putty.

- Follow manufacturer instructions for accurate mixing of components.

- Apply the epoxy putty evenly and uniformly, considering any thickness requirements.

- Use appropriate personal protective equipment (PPE) during handling and application.

- Consider reinforcement materials for enhanced structural strength if needed.

- Allow sufficient curing time before subjecting the repaired area to loads.

- Regularly inspect and maintain the repaired or reinforced areas.

- Keep detailed records of epoxy putty applications.

- Stay updated on industry best practices and advancements.

- Collaborate and network with colleagues and experts in the field.

- Conduct tests or seek professional consultation for critical or complex projects.

- Store and handle the epoxy putty properly to maintain its effectiveness.

- Dispose of leftover or expired materials responsibly.

Summary of suggestions and tips for conductors working with FRP epoxy putty:

- Familiarize yourself with the specific FRP epoxy putty product and its application guidelines.

- Ensure proper surface preparation for adequate bonding.

- Follow manufacturer instructions for accurate mixing of epoxy putty components.

- Apply the epoxy putty evenly and uniformly, ensuring complete coverage.

- Consider curing requirements and provide the appropriate environment.

- Allow sufficient curing time before subjecting the repaired area to stress or load.

- Ensure epoxy putty application does not interfere with electrical conductivity or connections.

- Regularly inspect and maintain the repaired areas.

- Keep records of epoxy putty applications and relevant data.

- Stay updated on industry standards and best practices.

- Collaborate with colleagues and experts for knowledge exchange.

- Seek professional consultation for critical projects.

- Adhere to safety protocols and use proper personal protective equipment.

- Dispose of leftover or expired materials responsibly.

Application Instructions for FRP Epoxy Putty:

Surface Preparation:

- Ensure the surface is clean, dry, and free from dust, grease, or loose materials.

- Remove any existing coatings or contaminants that may affect adhesion.

- If necessary, roughen the surface to improve the bond strength of the epoxy putty.

Mixing:

- Follow the manufacturer’s instructions for mixing the epoxy putty components.

- Use the recommended ratios and blending techniques to achieve the desired consistency.

- Use clean tools and containers for mixing to prevent contamination.

Application:

- Apply the mixed epoxy putty onto the prepared surface using a suitable tool, such as a putty knife or spatula.

- Spread the putty evenly and uniformly, ensuring complete coverage of the repair area.

- Shape and smooth the putty as needed to achieve the desired surface finish.

- Pay attention to any specific thickness requirements or layering techniques specified by the manufacturer.

Curing:

- Allow the epoxy putty to cure according to the recommended curing time provided by the manufacturer.

- For proper curing, provide the necessary environmental conditions, such as temperature and humidity.

- Avoid mechanical stress or load on the repaired area during the curing process.

Inspection and Maintenance:

- Regularly inspect the repaired area for any signs of damage or deterioration.

- Address any issues promptly to maintain the integrity of the repair.

Follow any additional instructions or maintenance recommendations provided by the manufacturer.

Raw Material Inspection:

- Inspect and verify the quality and specifications of the FRP epoxy putty raw materials before use.

- Check for any deviations or inconsistencies that may affect the performance of the epoxy putty.

Mixing and Consistency:

- Ensure the epoxy putty components mix accurately according to the manufacturer’s instructions.

- Monitor the consistency of the mixed epoxy putty to ensure it meets the desired specifications.

- Perform periodic checks to confirm consistent mixing and maintain a uniform product.

Application Testing:

- Conduct application tests to verify the compatibility and effectiveness of the epoxy putty on different surfaces and conditions.

- Assess the ease of application, adhesion properties, and curing time to ensure they meet the required standards.

- Evaluate the cured epoxy putty’s strength, durability, and appearance.

Adherence to Standards and Specifications:

- Refer to relevant industry standards, specifications, and guidelines for applying FRP epoxy putty.

- Ensure compliance with specific project requirements and regulations.

- Regularly review and update quality control procedures to align with any changes in standards or specifications.

Quality Assurance Documentation:

- Maintain detailed records of quality control inspections, tests, and results.

- Document any deviations or non-conformities encountered during the QC process.

- Establish a traceability system to track the batch or lot numbers of the epoxy putty used in each project.

Equipment Calibration and Maintenance:

- Regularly calibrate and maintain equipment used in the QC process to ensure accuracy and reliability.

- Keep records of equipment maintenance and calibration activities to ensure traceability and consistency.

Training and Competence:

- Train QC personnel on the proper procedures and techniques for inspecting and testing FRP epoxy putty.

- Ensure QC personnel understand the product specifications, application guidelines, and quality control requirements.

Continuous Improvement:

- Establish a feedback loop with end-users to gather feedback on the performance and quality of the FRP epoxy putty.

- Use the feedback to identify areas for improvement in the manufacturing process or product formulation.

- Implement corrective actions and preventive measures to enhance the quality of the epoxy putty and optimize its performance.

technical documents

Photo Gallery

Technical documentation request

Frequently Asked Questions

What is FRP epoxy putty?

FRP epoxy putty is a two-component gray paste of resin and mineral powders with high viscosity. Epoxy putty can be used for laying surfaces or as concrete repair mortar. Epoxy putty has very high mechanical characteristics, such as high penetration resistance, high adhesive strength, high impact wear resistance, etc.

What applications does FRP epoxy putty include?

FRP epoxy putty is widely used for the purpose of bedding materials for concrete surfaces in retrofitting projects. In addition, this putty can be used to fill holes, fix surface damages of concrete, stick metal plates and composite sheets to concrete surfaces, etc.

What materials is FRP epoxy putty made of?

FRP epoxy putty is made of epoxy resin concentrated with special mineral and industrial powders.

Which surfaces can epoxy putty be used on?

FRP epoxy putty, due to its high viscosity, can be used on vertical surfaces without spilling, in addition to horizontal surfaces.

What is the mixing ratio of epoxy putty components?

FRP epoxy putty is made with a ratio of 5 parts of component A to 1 part of component B.

What color is FRP epoxy putty?

Epoxy FRP putty consists of two components. The first part of this product is a hard gray paste and the second part is transparent. After mixing these two components together, a gray paste is obtained.

What is the resin used in FRP putty?

In making this type of FRP putty, epoxy resin has been used due to its excellent mechanical characteristics and properties.

What features does FRP epoxy putty include?

Epoxy FRP has unique features such as excellent adhesion to most construction materials, especially concrete, high stability against impact and vibrations, ease of application, low odor during application, high viscosity, which is used on surfaces. It has given verticality without scaling, high resistance to corrosion, etc., are among the features of FRP epoxy putty.

How much is special epoxy putty?

Epoxy FRP putty has a specific weight equal to 1.75 kg per liter.

How much is the price of FRP epoxy putty?

Epoxy putty is priced and sold per kilogram. It is not possible to provide a single price due to the fluctuations in the market. For inquiries or detailed information on the price of FRP epoxy putty, you can contact our experts in Afzir.

Be the first to review “FRP Epoxy Putty”