PRODUCT DESCRIPTION

Carbon Fiber Reinforced Polymer Rebar (CRR™) is a high-strength, lightweight polymer that incorporates carbon fiber. This innovative rebar offers a viable alternative to traditional steel reinforcement in various concrete structures, including parking structures, bridge decks, highways in extreme environments, and structures prone to corrosion and magnetic fields. The exceptional properties of CFRP Rebar make it particularly well-suited for the construction industry, facilitating the creation of sturdy structures such as condominiums, office buildings, and shopping malls.

FRP carbon rebars are composite materials comprising a combination of carbon fiber and a heat-resistant polymer resin, such as epoxy hardener or polyester resin. Steel rebars in structures exposed to severe corrosion present concerns regarding rust and concrete failure, and alternative solutions like galvanized coatings, polymer-impregnated concretes, and epoxy coatings have been explored. However, the popularity of FRP rebars, especially those made from carbon materials, has been growing due to their superior mechanical strength and excellent curing properties. The resistance to deformation and modulus of elasticity of carbon rebars are influenced by factors such as the percentage of fiber volume, the type of epoxy or polyester resin used, and meticulous control during production. Commonly available sizes for this type of FRP reinforcement range from grade sizes 6 to 14, and even larger sizes up to 25 can be obtained.

The utilization of CFRP carbon rebars offers numerous advantages in construction projects. Firstly, their lightweight nature simplifies transportation and installation, reducing labor and overall project costs. This is particularly beneficial when dealing with weight restrictions or challenging access conditions. Additionally, CFRP carbon rebars exhibit excellent resistance to corrosion, eliminating concerns about rust and concrete deterioration. This extends the lifespan of structures, reducing maintenance and repair expenses in the long run.

Moreover, CFRP carbon rebars provide enhanced structural performance. Their high tensile strength enables them to withstand heavy loads and extreme conditions, ensuring the durability and stability of concrete structures. This makes them an ideal choice for projects where structural integrity is crucial, such as high-rise buildings and infrastructure subjected to magnetic fields or corrosive environments.

Furthermore, the use of CFRP carbon rebars aligns with sustainable construction practices. They have a lower carbon footprint compared to traditional steel rebars and contribute to reducing overall energy consumption during construction. This eco-friendly characteristic promotes environmental stewardship and supports green building initiatives.

In conclusion, CFRP carbon rebars (CRR™) offer a versatile and superior alternative to steel reinforcement in concrete structures. Their lightweight nature, corrosion resistance, high tensile strength, and sustainability make them a preferred choice in construction projects. By embracing CFRP carbon rebars, builders and engineers can achieve long-lasting, resilient, and cost-effective structures in a variety of challenging environments.

Key Features

- Effective anchoring into adjacent members

- Non-corrosive

- Light-weight

- High-strength

- Low impact on member appearance and aesthetically pleasing

- Effective topside reinforcing product for slabs and beams

- Suitable replacement for steel rebars

- Tensile strength greater than steel

- Transparent to magnetic fields and radio frequencies

- Electrically and thermally non-conductive

- Impervious to chloride ion and chemical attack

Applications

- Pit Stabilization

- Surface Strengthening:

- Masonry Structure Reinforcement

- Capacity Upgrading

Packaging

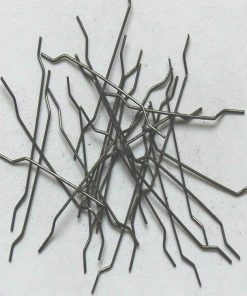

- In a variety of rebar diameters

Colour

- black

technical specifications

| Tensile strength |

2068MPa |

| Modulus of elasticity |

131GPa |

| elongation |

1.58% |

|

Fiber volume fraction |

70% |

| Matrix type |

Epoxy resin, vinyl ester |

Application Instructions for CFRP Carbon Rebars:

-

Surface Preparation:

Ensure that the surface where the CFRP carbon rebars will be installed is clean, free from dirt, dust, grease, or any loose particles. It should also be structurally sound and free from any defects that may affect the bonding of the rebars.

-

Adhesive Selection:

Choose an appropriate epoxy adhesive specifically designed for bonding CFRP carbon rebars. Follow the manufacturer’s instructions regarding the mixing ratio and application method.

-

Rebar Placement:

Determine the required length and position of the CFRP carbon rebars based on the design specifications. Cut the rebars to the appropriate length and carefully position them on the prepared surface according to the reinforcement plan.

-

Bonding Process:

Apply the epoxy adhesive evenly onto the surface where the CFRP carbon rebars will be bonded. Ensure full coverage and proper thickness of the adhesive layer.

-

Rebar Installation:

Place the CFRP carbon rebars onto the adhesive-coated surface, pressing them firmly into place to achieve good contact between the rebar and the adhesive. Use appropriate tools or clamps, if necessary, to hold the rebars in position until the adhesive cures.

-

Curing Time:

Allow the epoxy adhesive to cure according to the manufacturer’s instructions. Maintain appropriate temperature and humidity conditions during the curing process to ensure optimal bonding.

-

Quality Control:

Inspect the installed CFRP carbon rebars for proper alignment, adhesion, and overall quality. Verify that they meet the required specifications and design requirements.

-

Post-Installation:

If necessary, apply additional protective coatings or finishes to the rebars or the surrounding area to provide further durability, corrosion resistance, or aesthetic enhancement.

- Familiarize yourself with CFRP carbon rebars and their application guidelines.

- Consider project requirements, structural design, and load conditions.

- Collaborate with experienced structural engineers for optimal design solutions.

- Conduct a comprehensive structural analysis for sizing and placement of rebars.

- Choose high-quality CFRP carbon rebars from reputable manufacturers.

- Perform testing and evaluation to ensure compatibility and performance.

- Select appropriate epoxy adhesive based on project requirements.

- Supervise installation for proper placement, alignment, and bonding.

- Maintain detailed documentation for future reference and quality control.

- Stay updated through continuing education and collaborate with professionals.

Following these recommendations will help engineers effectively utilize CFRP carbon rebars, ensuring successful design, installation, and performance of reinforced structures.

Training:

Ensure contractors receive proper training on handling, cutting, and installing CFRP carbon rebars.

Compliance:

Adhere to manufacturer’s guidelines and specifications for the storage, handling, and installation of CFRP rebars.

Quality Control:

Implement a robust quality control process to verify the proper placement and alignment of CFRP carbon rebars during installation.

Collaboration:

Maintain effective communication and coordination with engineers and designers to ensure proper integration of CFRP rebars into the construction process.

Adhesive Application:

Follow manufacturer’s instructions for applying the epoxy adhesive, ensuring correct coverage and thickness.

Safety Precautions:

Enforce safety protocols to protect workers during the handling, cutting, and installation of CFRP carbon rebars.

Inspection:

Regularly inspect the installation of CFRP rebars to detect any defects or issues that may compromise their performance.

Record-Keeping:

Maintain accurate records of CFRP carbon rebar installation, including documentation of placement, quantities, and any deviations from the design specifications.

Collaboration with Suppliers:

Work closely with reputable suppliers to ensure timely delivery of high-quality CFRP carbon rebars and necessary materials.

Education and Training:

Stay updated on industry advancements and best practices for working with CFRP rebars through continuous education and training programs.

By following these recommendations, contractors can ensure the successful and efficient installation of CFRP carbon rebars in construction projects while maintaining quality, safety, and compliance with design requirements.

Quality Control Items for CFRP Carbon Rebars:

- Material inspection

- Adhesive quality assessment

- Bond strength testing

- Rebar placement and alignment check

- Adhesive coverage verification

- Visual inspection for defects

- Pull-out tests for anchorage strength

- Documentation of quality control activities

- Compliance with industry standards

- Independent testing for verification.

technical documents

Photo Gallery

Technical documentation request

Frequently Asked Questions

What are the individual characteristics of carbon rebars?

Carbon rebars with very high tensile strength are mostly used in pre-stretched concrete systems and retaining walls to stabilize the pit such as the anchorage system. Carbon rebars also have good resistance to corrosion and chemical reactions.

What sizes of carbon rebars are available?

Common sizes for carbon rebars are grade sizes 6, 8, 10, 12, 14 and even up to 25.

What do you know about carbon rebars?

These types of rebars are rods made of carbon or composite resin that are prefabricated and have high strength and are used as internal or external reinforcement to create more strength and higher tensile warp.

How much is the tensile strength of carbon rebars?

The tensile strength is 2068MPa.

Be the first to review “CFRP Carbon Rebar”