PRODUCT DESCRIPTION

FRP Profiles:

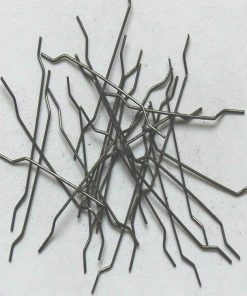

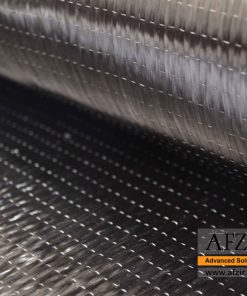

FRP profiles are composite materials made of carbon fiber, glass fibers, or aramid fibers embedded in a polymer resin, such as epoxy or polyester. These profiles come in different shapes, like angles, channels, plates, etc. They are an alternative to steel profiles in environments with corrosion or strong magnetic fields. The production methods include pultrusion and fiber twisting. FRP profiles have a specific gravity of about a quarter and a third of aluminum compared to steel. They offer excellent tensile strength and should not be bent during installation due to using heat-treated polymers. The unique construction of FRP profiles allows for limitless possibilities in profile shapes.

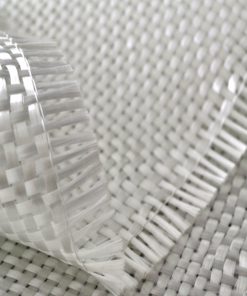

FRP Gratings:

FRP gratings are made from unsaturated polyester and fiberglass using pultrusion technology. These gratings are designed with a specific opening rate. They possess the strength of steel while being resistant to corrosion. FRP gratings are widely used due to their high strength, lightweight nature, long lifespan, and enhanced safety features. All FRP gratings meet stringent international standards. Compared to steel grating, molded fiberglass grating has a higher strength-to-weight ratio, making it easy to handle and quick to install.

FRP profiles and composite sections are particularly suitable for structures exposed to highly corrosive environments or those with intense magnetic fields. Combining the exceptional properties of FRP materials with their durability in harsh conditions, they serve as a viable alternative to traditional steel and concrete materials. These FRP solutions offer superior strength, extended lifespan, and cost-effectiveness, making them an excellent choice for various structural applications.

Several factors can influence the price of FRP profiles and composite sections. These factors include:

-

Dimensions:

The size and dimensions of the profiles or sections can impact the cost. Larger or customized sizes may require additional materials and manufacturing processes, leading to higher prices.

-

Design Complexity:

Complex designs with intricate shapes or unique features may involve additional production steps or specialized manufacturing techniques, which can increase the price.

-

Quantity:

The quantity of FRP profiles or sections needed for a project can affect pricing. Bulk orders or larger quantities often come with volume discounts or more favorable pricing.

-

Material Selection:

Different types of FRP materials or composite formulations may have varying costs. Factors such as the quality of resin, reinforcement fibers, and additives can influence pricing.

-

Surface Finish or Treatment:

Additional surface finishes, coatings, or treatments, such as gel coating or protective layers, can add to the overall cost of FRP profiles or sections.

-

Project Requirements:

Specific project requirements, such as certifications, industry standards, or testing, can impact the price. Compliance with certain regulations or specifications may involve additional costs.

-

Market Conditions:

Market dynamics and supply-demand factors can influence the pricing of FRP profiles and composite sections. Fluctuations in raw material costs, manufacturing capacity, or market competition can all contribute to price variations.

It is essential to consult with manufacturers, suppliers, or distributors to obtain detailed pricing information based on your specific project requirements and specifications, f carbon fiber, glass fibers, or aramid fibers embedded in a polymer resin, such as epoxy or polyester. These profiles come in different shapes, like angles, channels, plates, and more. They are an alternative to steel profiles in environments with corrosion or strong magnetic fields. The production methods include pultrusion and fiber twisting. FRP profiles have a specific gravity of about a quarter and a third of aluminum compared to steel. They offer excellent tensile strength and should not be bent during installation due to using heat-treated polymers. The unique construction of FRP profiles allows for limitless possibilities in profile shapes.

Key Features

- Lightweight and high strength for easy handling and installation.

- Non-metallic construction for rust and corrosion resistance.

- Flame-retardant and nonmagnetic insulation.

- Excellent impact resistance with slight deformation.

- Versatile design and specifications to meet diverse demands.

- Anti-skid surface with comfortable stepping.

- Long service life and low maintenance.

- Wide range of colors for an appealing appearance.

Applications

- chemical processing

- food facilities

- marine

- oil & gas

- electricity application

- manufacturing

- construction numerous architectural uses

- pharmaceutical

- metals & mining

- pulp & paper

- recreation and water parks

- telecommunications and IT server farms

- shipping centers

- transportation facilities

- water & waste treatment

Packaging

- FRP Profiles are produced with different materials in the form of CFRP profiles (carbon profiles), GFRP (glass profiles), AFRP (aramid or Kevlar profiles) and in the form of corner sections, sheets

Colour

- Fits customer needs

technical specifications

- Familiarize yourself with FRP materials: Understand the properties and limitations of FRP profiles and grating.

- Follow industry standards and guidelines: Adhere to relevant standards for design, installation, and performance.

- Conduct structural analysis: Determine load-bearing capacity and design requirements.

- Collaborate with manufacturers and suppliers: Seek their expertise in product selection and installation techniques.

- Optimize material selection: Consider factors such as chemical resistance and traffic loads.

- Ensure proper installation: Follow recommended procedures for surface preparation, adhesive application, and fastening.

- Consider long-term maintenance: Assess cleaning, inspection, and repair needs for sustained performance.

- Stay updated on advancements: Stay informed about new technologies and techniques in FRP materials.

- Understand the project requirements: Familiarize yourself with the project specifications and design plans involving FRP profiles and grating.

- Select reputable suppliers: Choose reliable suppliers who provide high-quality FRP materials and have a good track record in the industry.

- Ensure proper storage and handling: Store FRP profiles and grating in a dry, controlled environment to prevent damage or degradation.

- Prepare the installation area: Clean and prepare the surface to ensure proper adhesion and installation of the FRP profiles and grating.

- Follow manufacturer’s guidelines: Adhere to the manufacturer’s recommended installation procedures and instructions for the specific FRP products being used.

- Use appropriate tools and equipment: Utilize the correct tools and equipment for cutting, drilling, and fastening FRP profiles and grating.

- Ensure proper alignment and spacing: Follow the design plans to ensure accurate placement and alignment of FRP profiles and grating.

- Perform quality control checks: Regularly inspect the installed FRP materials to ensure they meet the required specifications and standards.

- Provide proper support and protection: Take necessary precautions to protect the installed FRP profiles and grating during construction activities.

- Coordinate with other trades: Communicate and coordinate with other contractors involved in the project to ensure a smooth installation process.

- Train and educate the workforce: Provide training and instructions to the workers involved in installing FRP profiles and grating to ensure proper handling and installation techniques.

- Maintain records and documentation: Keep accurate records of installation procedures, inspections, and any modifications made during the project.

- Follow safety guidelines: Adhere to all safety regulations and guidelines to ensure a safe working environment for the workers and the successful completion of the project.

- Surface Preparation: Ensure the installation surface is clean, dry, and free from any debris, grease, or contaminants that may hinder proper adhesion. Remove any loose or damaged material from the surface.

- Adhesive Selection: The manufacturer recommends a suitable adhesive for bonding FRP profiles and grating. Follow the manufacturer’s instructions regarding the mixing ratios, application methods, and curing times.

- Cutting and Sizing: Use appropriate tools to cut and size the FRP profiles and grating according to the project requirements. Take necessary precautions to prevent splintering or damaging the material during cutting.

- Adhesive Application: Apply the adhesive to the prepared surface and the mating surfaces of the FRP profiles and grating according to the manufacturer’s instructions. Ensure that the adhesive is applied evenly and covers the entire bonding area.

- Positioning and Pressing: Place the FRP profiles and grating onto the adhesive-coated surface and align them properly. Apply even pressure along the length or surface area to ensure proper contact and bonding between the materials.

- Curing and Setting Time: Allow sufficient time for the adhesive to cure and set as per the manufacturer’s recommendations. Avoid any disturbance or movement of the installed FRP profiles and grating during curing.

- Quality Control Inspection: Conduct a visual inspection to ensure the FRP profiles and grating are securely bonded and properly aligned. Check for any gaps, voids, or signs of adhesive failure. Rectify any issues promptly.

- Cleaning and Maintenance: Clean any excess adhesive or smudges from the FRP profile’s surface and grate using the recommended cleaning agents. Follow proper maintenance procedures to extend the lifespan of the installed FRP materials.

- Documentation: Keep detailed records of the installation process, including photographs, drawings, and any modifications made. Document the adhesive type, batch numbers, and curing times for future reference.

- Inspection of Raw Materials: Thoroughly inspect the FRP profiles and grating materials to ensure they meet quality standards and are defect-free.

- Dimensional Accuracy: Verify the precise dimensions of the FRP profiles and grating, including length, width, thickness, and tolerances.

- Visual Inspection: Conduct a visual examination for surface defects like cracks, chips, delamination, or uneven texture.

- Mechanical Testing: Perform tests to assess mechanical properties such as tensile strength, flexural strength, impact resistance, and load-bearing capacity.

- Adhesive Bonding Quality: Evaluate the strength and integrity of adhesive bonding between components through pull-off or shear tests.

- Corrosion Resistance: Test the FRP profiles and grating for resistance to corrosion, either through accelerated corrosion tests or exposure to corrosive environments.

- Fire Performance: Assess the fire resistance capabilities of the materials by conducting tests that measure flame spread, smoke generation, and heat release.

- Ultraviolet (UV) Resistance: Test the ability of the FRP profiles and grating to withstand prolonged UV exposure without significant degradation or discoloration.

- Documentation and Traceability: Maintain comprehensive records of quality control activities, including test results, inspection reports, and material traceability.

- Continuous Monitoring: Implement a robust quality control program that includes regular monitoring of the production process, periodic sampling, and continuous improvement initiatives.

technical documents

Photo Gallery

Technical documentation request

Frequently Asked Questions

How are FRP profiles offered in the market?

Depending on the specific type of construction of these materials, FRP sections can be made in different types and profiles, which mainly include FRP circular sections, FRP square sections, FRP rectangular sections, FRP channel, FRP rod and H-shaped section.

What are the main materials used in FRP profiles?

The basic composition of FRP profiles is resin and glass fibers, which use resins as adhesives and glass fibers as a material that resists stress.

In what colors are FRP profiles marketed?

Different colors of yellow, green, blue and red can be used to make FRP profiles.

What dimensions of FRP profiles are offered to the customer?

Due to the manufacturing method and ease of cutting, FRP profiles can be produced in the dimensions and thicknesses desired by the customer.

Be the first to review “FRP Profiles and Grating”