PRODUCT DESCRIPTION

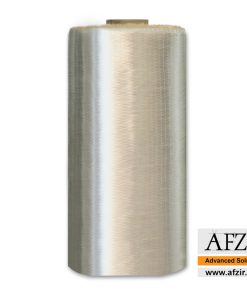

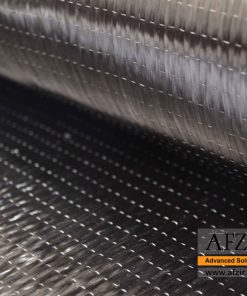

The FRP laminate epoxy resin adhesive is a versatile and reliable product suitable for various applications. Its primary purpose is to bond FRP laminates to concrete surfaces, making it an ideal choice for reinforcing structures. This two-component adhesive consists of two resins and a hardener, providing excellent bonding capabilities for internal and external surfaces.

One of the key advantages of the FRP laminate epoxy resin adhesive is its ability to maintain its mechanical and chemical properties even under temperature changes. It exhibits exceptional adhesion and strength, ensuring a durable and long-lasting bond that can withstand the damaging effects of vibrations.

The thixotropic nature of this adhesive is noteworthy as it does not contain solvents or water. This feature allows for easy application on various substrates, including those that are challenging to adhere to. As a result, the FRP laminate epoxy resin adhesive finds wide application in electronics, industrial manufacturing, structural engineering, and even in the jewelry industry, thanks to its versatility and reliable performance.

Which factor can affect the price of FRP Epoxy Laminate Adhesive?

Several factors can influence the price of FRP epoxy laminate adhesive. Here are some key factors:

Brand and Quality:

Different brands may offer FRP epoxy laminate adhesives at varying prices based on their reputation, quality, and performance. Higher-quality adhesives often come with a higher price tag.

Quantity:

Bulk purchasing of FRP epoxy laminate adhesive typically results in discounted prices. The larger the quantity you purchase, the lower the unit price may be.

Formulation and Features:

Adhesives with specialized formulations or additional features, such as enhanced strength, fast curing time, or specific certifications, may have higher prices compared to standard adhesives.

Market Demand and Competition:

Market demand and competition can affect pricing. If the request for FRP epoxy laminate adhesive is high and there are limited suppliers, prices may be higher. Conversely, if there is intense competition among suppliers, it could lead to more competitive pricing.

Location:

Prices vary based on regional factors, including transportation costs, taxes, and local market dynamics.

Supplier and Distribution Channels:

Different suppliers and distribution channels may have different pricing structures, margins, and overhead costs, which can impact the final price of the adhesive.

It’s essential to consider these factors and consult with suppliers or manufacturers to get accurate pricing information based on your specific requirements and location.

Key Features

- Exceptional adhesion resistance throughout the bonding process.

- Easy application and user-friendly.

- Excellent resistance to sustained loads.

- Adequate adherence to surfaces, such as concrete, steel, and stone.

- Minimizes cracking through non-shrinkage hardening.

- Resilient against impacts and temperature fluctuations.

- Superior ability to penetrate and seal fine cracks on concrete surfaces.

- Displays excellent chemical stability.

- Well-suited for vertical surface applications.

- Demonstrates high mechanical strength.

- No need for primer application

Applications

- Covering concrete surfaces against moisture with FRP epoxy laminate resin adhesive

- Can be used in urban areas

- Bonding new concrete to old concrete with FRP laminate epoxy adhesive

- Connecting FRP laminate to concrete surfaces

- Use FRP laminate epoxy adhesive as sealant and insulation on doors and windows

- Jointing of precast segmental bridge units

- Bonding rubber bearing pads for highways and railway

Packaging

- –

Colour

- grey

technical specifications

|

Chemical base |

Resin epoxy |

|

density |

1535 Kg/m3 |

| compressive strength |

85 MPa |

|

Tensile strength |

17 MPa |

| Fracture strain |

4% |

|

Curing temperature |

5℃-30℃ |

Surface Preparation:

Ensure the bonding surfaces are clean, dry, and free from dust, grease, or loose particles. It is recommended to roughen the surfaces to promote better adhesion.

Mixing:

Thoroughly mix the two components of the epoxy adhesive, typically component A (white paste) and component B (grey paste), in the specified proportions provided by the manufacturer. Follow the mixing instructions carefully to achieve a uniform and consistent mixture.

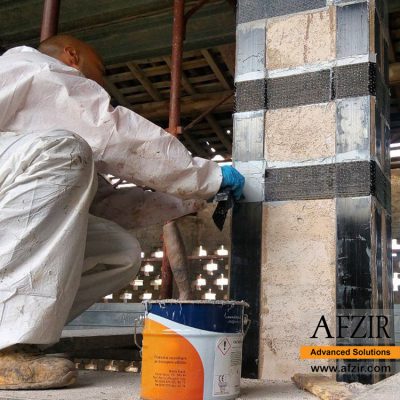

Application:

Apply the mixed epoxy adhesive to one of the bonding surfaces using a suitable applicator, brush, or trowel. Ensure an even and sufficient coverage to achieve proper bonding.

Joining and Clamping:

Carefully align the surfaces to be bonded and firmly press them together. Apply sufficient pressure or use clamps to hold the surfaces in place during curing. Follow the manufacturer’s recommendations for clamping time and pressure, if specified.

Curing:

Allow the adhesive to cure according to the recommended curing time provided by the manufacturer. Maintain the recommended temperature and environmental conditions during the curing process for optimal bond strength.

Finishing:

After fully cured, an excess adhesive can be removed using appropriate cleaning methods or tools. Follow the manufacturer’s instructions for post-application cleaning and finishing, if applicable.

technical documents

Photo Gallery

Technical documentation request

Frequently Asked Questions

What is Frp Laminate Epoxy Adhesive?

Frp epoxy laminate adhesive has a highly adhesive that can provide excellent bonding between concrete and Frp sheets or laminates or other building materials. These adhesives are made of epoxy resin and hardener in predetermined proportions.

What are the features of Frp laminate epoxy adhesive?

FRP epoxy laminate adhesives have excellent properties such as very good resistance under constant loads, excellent adhesion to all types of concrete, steel, stone, etc., non-shrinkage and hardening, impact resistance and temperature change, excellent chemical stability and ... enjoys.

What color is Frp laminate epoxy adhesive?

Frp epoxy laminate adhesives are gray after final mixing of its components.

What are the uses of Frp epoxy laminate adhesive?

The most common application of Frp laminate epoxy adhesive, due to its very high adhesive strength, is seen in the installation of Frp laminates on concrete surfaces for reinforcement. However, this adhesive is also used in the installation of most building materials, such as steel, on concrete surfaces.

How many parts is Frp laminate epoxy adhesive?

Frp epoxy laminate adhesive consists of two components. One component of these adhesives is epoxy resin and the other is a hardener.

How much is Frp laminate epoxy adhesive gel?

Frp laminate epoxy adhesive provides 30 minutes of working time or gel time at 20 °C.

What is the price of Frp laminate epoxy adhesive?

Frp laminate epoxy adhesive is sold in the market per kilo. It is not possible to offer a single price due to fluctuations in the market. For this purpose, you can contact our experts in Afzir to inquire about the exact price of Frp laminate epoxy adhesive.

How to make Frp laminate epoxy adhesive?

You can apply for Frp laminate epoxy adhesive through suppliers of building materials as well as suppliers of reinforcement materials. Afzir Reinforcement Company is one of the most experienced companies in the field of supplying reinforcement materials, consulting, design and execution.

At what levels can Frp laminate epoxy be applied?

Frp epoxy laminate adhesive, due to its good viscosity, can be used on both horizontal and vertical surfaces.

What is the proper temperature for applying Frp laminate epoxy adhesive?

The best temperature for the best results from Frp laminate epoxy adhesives is 5 to 30 degrees Celsius.

Be the first to review “FRP Epoxy Laminate Adhesive”