PRODUCT DESCRIPTION

Our Two Component Acrylic Paint Waterproof (designated as APW™ code) is a high-quality solution designed to provide exceptional waterproofing and protection for a wide range of surfaces. This versatile paint can be applied effortlessly using spray, roller, or brush techniques, making it suitable for various projects, including pool walls, concrete structures, and any surface that requires reliable waterproofing.

One of the standout features of our Two Component Acrylic Paint Waterproof is its long-lasting durability, which eliminates the need for frequent repainting. This saves valuable time and significantly reduces maintenance costs associated with concrete structures. Utilizing this innovative paint can achieve reliable and cost-effective waterproofing solutions.

Our Two Component Acrylic Paint Waterproof formulation involves combining high-quality acrylic resin with acrylic base colors. This unique blend results in a two-part acrylic insulation that effectively seals swimming pools, concrete structures near water, and other moisture-prone surfaces. The core material of the insulation is a two-component resin derived from premium acrylic polymers, ensuring exceptional strength and durability.

When combined with a precisely calibrated ratio of specially formulated colors, the two-component acrylic insulation resin transforms into a smooth paste that serves as the final product. This paste offers superior adhesion and a protective barrier against water, ensuring reliable waterproofing and resistance to weather conditions and temperature changes. Regardless of external factors, our Two Component Acrylic Paint Waterproof provides long-lasting protection.

To ensure optimal performance, our Two Component Acrylic Paint Waterproof requires on-site mixing. Combining the provided cement powder with the acrylic resin allows you to create a customized solution that meets your specific project requirements. The flexibility of this system allows for different proportions of the two components, resulting in a product with varying levels of flexibility to cater to various applications.

With our Two Component Acrylic Paint Waterproof, you can achieve efficient and durable waterproofing solutions that protect your structures and provide cost savings in the long run. Experience the benefits of our high-quality, easy-to-use paint and enjoy peace of mind with reliable waterproofing.

Features

- High elasticity

- Simple implementation

- No need for specialized and skilled personnel

- Anti-algae growth

- Unification of the final color of the pool or concrete structure and the insulation coating

- reduction in costs

Applications

- Sealing pools, water tanks, water pipes, dams, tunnels, bridges, channels, foundations of buildings, Kitchen, Toilets, seams and cracks

- Roof insulation: The product can be used to insulate all types of concrete, wooden, metal and gable roofs. This product is a good alternative to bituminous.

- Use as thermal insulation

- Due to the high technical characteristics of the product, it can be used as traffic colors. Because this product maintains its durability under traffic loads and all kinds of weather conditions.

- Coloring tables, Urban furniture painting, Covering the exterior of buildings

- Increased resistance to weather conditions

- Anti-rust metal structures

Packaging

- Acrylic resin in 5 and 20 kg buckets and cement powder in 25 kg bags.

Colour

- grey and white

technical specifications

|

color |

Grey and white |

| density |

1.65 g/cm3 |

|

water adsorption |

0.30% |

| Optimal thickness |

1 mm |

|

Initial setting time |

3 hours |

| Storage time |

1 year |

- Familiarize Yourself with Product Specifications: Understand the product’s requirements and instructions.

- Conduct Surface Preparation: Ensure the surface is clean and repaired before application.

- Follow Mixing Guidelines: Accurately mix the components according to recommended ratios.

- Test Compatibility and Adhesion: Perform a small-scale test to assess adhesion and compatibility.

- Choose the Appropriate Application Method: Select the suitable paint application method.

- Follow Proper Safety Measures: Use protective gear and ensure proper ventilation.

- Allow Sufficient Curing Time: Give the product enough time to cure fully.

- Regular Maintenance and Inspection: Schedule routine checks to maintain the effectiveness of the waterproofing.

- Seek Manufacturer Support: Contact the manufacturer for guidance and assistance.

- Understand Product Specifications: Familiarize yourself with the paint’s requirements and instructions.

- Prepare the Surface Thoroughly: Ensure a clean and repaired surface before applying the paint.

- Follow Mixing Instructions: Accurately mix the components according to recommended ratios.

- Conduct Compatibility and Adhesion Tests: Test the paint’s compatibility and adhesion on a small scale.

- Select Appropriate Application Techniques: Choose a suitable method for applying the paint.

- Prioritize Safety Measures: Use protective gear and ensure proper ventilation.

- Allow Sufficient Curing Time: Give the paint enough time to cure fully.

- Implement Regular Maintenance: Schedule routine checks to maintain waterproofing effectiveness.

- Seek Manufacturer Support: Contact the manufacturer for guidance and assistance.

Surface Preparation:

- Ensure the surface is clean, free from dust, dirt, and grease.

- Repair any cracks, holes, or imperfections on the surface.

- Remove loose particles and debris using a brush or vacuum cleaner.

Mixing:

- Wear appropriate protective gear such as gloves and goggles.

- Open the containers of the two components: acrylic resin and color mixture.

- Stir each component separately to ensure uniformity.

- Pour the required amount of acrylic resin into a clean mixing container.

- Gradually add the color mixture to the resin, following the recommended mixing ratio provided by the manufacturer.

- Thoroughly mix the components using a mechanical stirrer or paddle until a homogeneous paste is obtained.

Application:

- Choose a suitable application method based on the project requirements, such as spray, roller, or brush.

- If spraying, adjust the nozzle settings to achieve the desired coverage and consistency.

- Start applying the Two Component Acrylic Paint Waterproof from the highest surface point, working your way down.

- Ensure even and consistent coverage, avoiding excessive buildup or thin spots.

- Use long, overlapping strokes to achieve a smooth and uniform finish.

- Pay special attention to corners, edges, and hard-to-reach areas, ensuring complete coverage.

- Allow the first coat to dry as per the manufacturer’s instructions.

- Apply a second coat if necessary for enhanced protection and coverage. Follow the recommended drying time between coats.

Curing:

- After the final coat, allow the Two Component Acrylic Paint Waterproof to cure undisturbed for the specified duration, typically 24 to 48 hours.

- Protect the painted surface from moisture, heavy traffic, and extreme temperatures during curing.

Clean-Up:

- Clean tools and equipment immediately after use with water or a recommended cleaning agent.

- Dispose of any leftover paint or empty containers following local regulations.

Note: It is essential to carefully read and follow the specific instructions provided by the Two Component Acrylic Paint Waterproof manufacturer, as application techniques and drying times may vary based on the product’s formulation and intended use.

- Pre-Production Quality Control: Verify raw materials and test components for quality.

- Production Process Control: Establish SOPs, calibrate equipment, and conduct in-process checks.

- Finished Product Inspection: Inspect visually, perform quality tests, and compare results with criteria.

- Packaging and Labeling: Ensure suitable packaging and accurate labeling of containers.

- Storage and Shelf-Life Control: Implement proper storage conditions and monitor inventory rotation.

- Document Control and Recordkeeping: Maintain comprehensive documentation of quality control activities.

- Continuous Improvement: Seek feedback, address quality issues, and promote employee engagement

technical documents

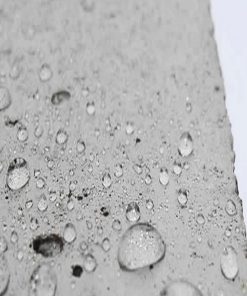

Photo Gallery

Technical documentation request

Be the first to review “Two Component Acrylic Paint Waterproof”