PRODUCT DESCRIPTION

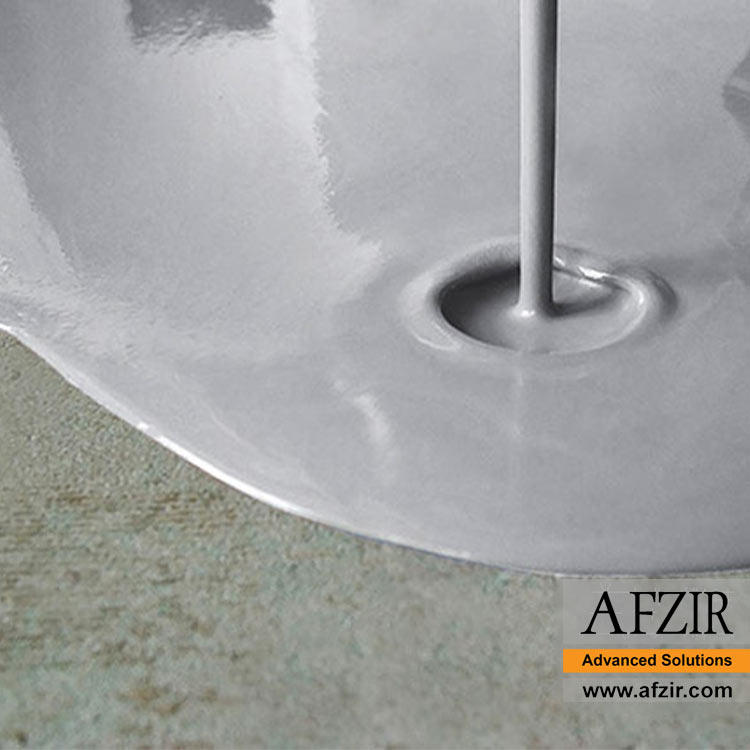

The Two-Component Self-Leveling Mortar (SLM™400 Code) is a superior and versatile solution designed for leveling uneven, damaged, or sloped surfaces before flooring application. This specially formulated two-part cementitious polymer cement mortar ensures a smooth, level finish with exceptional performance.

With its innovative composition, this self-leveling mortar offers compatibility with a wide range of flooring systems, including epoxy, polyurethane, and ceramic tiles. The presence of polymer additives enhances its flow properties and improves the alignment during the application, resulting in a flawless and uniform surface.

Notably, the unique blend of polymers used in this mortar provides exceptional adhesion properties, effectively bonding the mortar to the substrate. This not only increases the overall strength of the mortar but also ensures long-lasting durability.

The Two-Component Self-Leveling Mortar (SLM™400 Code) stands out for its ease of use and versatility in application methods. It can be conveniently applied using mechanical or manual techniques, offering flexibility to suit different project requirements.

This high-performance mortar offers efficient curing times, allowing for quicker project completion. After a mere 24 hours, the mortar achieves its final setting, and it can be walked on as early as 6 hours after application. Applying the mortar at a thickness of 60 mm per layer is recommended for optimal results.

Choose the Two Component Self-Leveling Mortar (SLM™400 Code) for its exceptional leveling capabilities, enhanced adhesion, and efficient curing times. Experience the reliability and quality it brings to your flooring projects. Contact us today to explore pricing and to acquire this top-of-the-line self-leveling mortar.

Features

- Polymer base modified mortar

- It has the property of self-alignment and high psychology

- Ability to smooth very uneven concrete surfaces

- Suitable for use on sloping surfaces

- The possibility of mortaring in thicknesses between 0 and 60 mm

- Excellent adhesion to dry or wet cement substrates

- Waterproof properties and resistance to positive and negative pressure up to 10 times.

- Fast hardening property

- Ease of implementation and no need for troweling

- Ability to run manually or mechanically

Applications

- Suitable for indoor and outdoor applications

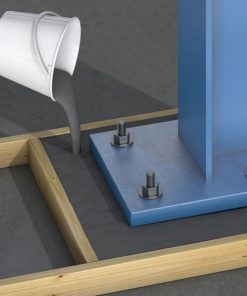

- For the implementation of level and sloping substrates and ramps

- For the implementation of concrete floor or yard area, especially uneven and compact concrete

- Repairing and increasing the life of damaged concrete floors in manufacturing plants, heavy industrial areas, helicopter platforms, etc.

- Suitable for local repairs

- Suitable for food factories

Packaging

- 30 kg bags

Colour

- Gray

technical specifications

| Mixing ratio |

31.25Kg per set |

| Thickness of layer |

Up to 60 mm |

| Ambient temperature |

5-35℃ |

| Pot life |

20min |

| Ambient humidity |

75% max |

|

application temperature |

5-15℃ |

| compressive strength (7 days) |

9N/mm2 |

| compressive strength (28 days) |

40N/mm2 |

| flexural strength (28 days) |

8N/mm2 |

- Familiarize yourself with the product specifications and application guidelines.

- Conduct proper surface preparation to ensure a clean and dry substrate.

- Follow the recommended mixing ratios for accurate and adequate mortar preparation.

- Choose suitable application methods, considering both manual and mechanical options.

- Consider ambient conditions such as temperature and humidity during application and curing.

- Adhere to recommended curing and drying times for optimal results.

- Ensure proper safety measures, including wearing appropriate personal protective equipment (PPE).

- Seek technical support from the manufacturer if needed for guidance or troubleshooting.

These recommendations will help engineers succeed with the Two Component Self-Leveling Mortar (SLM™400 Code).

- Thoroughly prepare the substrate by cleaning it and removing debris or contaminants.

- Follow the manufacturer’s instructions for accurately and appropriately mixing the two components.

- Apply the mortar evenly and smoothly, using suitable tools and techniques.

- Spread and level the mortar to achieve a uniform and flat surface.

- Allow sufficient time for the mortar to cure and dry without subjecting it to excessive traffic or loads.

- Conduct regular quality control inspections to ensure compliance with specifications.

- Maintain proper safety measures, including wearing appropriate personal protective equipment (PPE).

Substrate preparation:

Ensure the surface is dry and free from contaminants such as grease and dust, which may hinder adhesion. The floor temperature should be maintained above 5 degrees Celsius throughout the application and drying process of the lower layer. If there is an underfloor heating system, it should be turned off, or the substrate should be kept at a temperature of over 15 degrees Celsius for at least 48 hours before, during, and after applying the mortar.

Mixing method:

Follow the recommended ratio in the data sheet and pour the self-leveling cement base flooring onto the prepared subfloor. Use a trowel to spread and level the mortar. The mortar will self-level within the first 15 minutes of the 20-minute working time. At 30°C, a 3mm layer will be walkable after approximately 6 hours. The time may vary at lower temperatures and decrease at higher temperatures. It will also be reduced when applying thinner thicknesses on absorbent surfaces.

- Pre-Installation Inspection: Conduct a visual check of the substrate to ensure it is suitable and free from contaminants.

- Material Inspection: Verify the components for any defects and ensure proper packaging.

- Mixing Process: Follow the manufacturer’s instructions for accurately mixing the components.

- Application Verification: Monitor the application to ensure even and proper thickness.

- Curing and Drying: Allow sufficient time for the mortar to cure and dry according to recommendations.

- Bond Strength and Adhesion: Perform tests to verify the bond strength between the mortar and substrate.

- Surface Quality Inspection: Check for defects and ensure the surface meets the required standards.

- Documentation and Reporting: Maintain detailed records of inspections, test results, and any corrective actions taken.

technical documents

Photo Gallery

Technical documentation request

Be the first to review “Two Component Self Leveling Mortar”